Flat knitting is one of the most versatile textile technologies. The machines in use today range from hand driven machines to highly sophisticated electronic machines. Every type of machine has its advantages – and disadvantages. A large variety of products, from scarves to gloves, toe-socks to elaborate sweaters and technical items can be produced with flat knit technology. Claudia Ollenhauer-Ries from Germany reviews the various flat knitting technologies.

The flat knitting technology adds the textile design to the creation of apparel. Along with this comes the need of special know-how of the technology when going beyond plain basic shapes and workmanship. Even with basic designs, special treatments of the knitted goods and special machines for sewing have to be used.

Design work

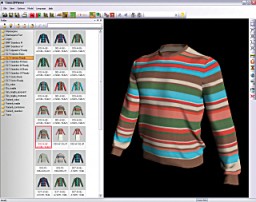

Designers often use samples, swatches and photographs to illustrate the look and technology desired in combination with sketches made by hand or by graphic computer software. They supply information about the gauge, the yarn, the knitting technology, the colours for sampling and supplementary colour ways as well as the measurements of the finished garment including the size specs. Some, but not all designers are trained on specific software provided by the knitting machine manufacturers, while others work with generic graphic software or specific graphic software for knitted structures. Some will also draw the sketches by hand.

Examples for graphic software to design knitwear including some simulation views and a database of yarns and patterns are: Kaledo Knit from Lectra, France, Eneas from Italy and Fashion Studio with its Easy Knit module from Nedgraphics, The Netherlands. These special design software programs are specially developed for the design of flat knitted items and could be used for circular knits as well.

Great brands of machine manufacturers

Among the international Flat Knitting machine brands are Stoll (Germany), Shima Seiki (Japan), Protti (Italy), Universal (Germany) and Steiger-Zamark (Switzerland/Italy). From China, come a handful of suppliers like Kauo Heng or Ningbo Yuren Knitting Machine. All of them have representatives in the major manufacturing destinations

Among the international leaders are Stoll (Germany), Shima Seiki (Japan), Protti (Italy), Universal (Germany) and Steiger-Zamark (Switzerland/Italy). From China, come a handful of suppliers like Kauo Heng or Ningbo Yuren Knitting Machine. Main accessories are the knitting needles, supplied by third party companies. Among these, Groz-Beckert (Germany), Sugiura Needle (Japan) and Christoph Liebers (Germany) are renowned suppliers. All of them have representatives in the major manufacturing destinations.

About technologies, gauges and yarn counts Flat knit items are distinguished by technology used, gauges and yarns used. The gauge (gg or E for English system) stands for the number of needles per inch: the lower the count is the coarser the knit, the higher the count, the finer the fabric. Typical gauges are 3, 5, 7, 10, 12, 14, 16 and 18gg (or written E3, E5 and so on). Most common are the gauges 5, 7 and 10.

Technologies used: single knit, ribs, cables, plating, jacquard, intarsia, multi gauge and whole garment knitting. Stoll-multi gauge is a registered trademark of Stoll’s and describes a technology of knitting several different gauges within one knitted piece. WholeGarment is a registered trademark of Shima Seiki and stands for the technology of knitting a complete garment including sleeve and collar as a ready-to-wear item. These two technologies multiply the possibilities of flat knitting – but require a lot of technical understanding. Of course, most of the leading knitting machines manufacturers offer these technologies – just using another designation.

The yarn counts used have to match the gauge, as the space between the needles restricts the thickness of the yarn. The yarn count should be given in tex (weight in grams divided by 1,000 m length, the tex number increases with the thickness of the yarn) or, more common for flat knits (at least in Europe), in metric count Nm (1 gram of yarn has a length of x metres, the Nm number decreases with the thickness of the yarn). Several ends of a fine yarn can be twisted (S or Z direction) or plied (no twisting) for the use in a coarser knit structure. A yarn with Nm 28/2 would be made of two ends of Nm 28 yarn and would have a final yarn count of Nm 14. A twisted yarn means one more preparation step in the twisting machine, thus more time and costs, and an even look of the yarn compared to a plied yarn. There is no mathematical rule which would correlate the gauge of the machine with the yarn count, as a lot depends on the structure of the yarn. A fluffy yarn would be finer in yarn count than a dense yarn. Both would be used on the same machine gauge.

Piece by piece

Flat knitting machines can produce several and different types of fabrics and preformed pieces like:

1. endless fabrics with a defined width, which is rather untypical for knitwear but could be relevant for technical uses;

2. sweater panels (front, back and sleeves) with a ribbed or tubular seam, defined length and width, typical for jacquard knits, which will be cut to shape and sewn with overlock/safety stitch afterwards. Cut & sew is a common name for this technique. Some twin machines with double carriages can knit two panels at the same time – saving time;

3. preformed front, back and sleeve panel for sweaters with narrowing/widening stitches, the so-called “fully fashioned” type. The measurements will be defined with a special patternmaking programme. No cutting will be necessary, the edges will be linked by special linking machines;

4. the already mentioned ready to wear sweaters, on which only further embellishment, labelling and saving of the two ends of the yarn at the beginning and end of the knit; no linking is necessary;

5. trimmings like collars, neckbands (used also for T-shirts and sweatshirts), belts or applications will be knitted separately, often with simpler machines designed for these purposes.

Assembling the pieces The knitted panels, if not fully fashioned, will have to be cut into shape. Patterns will be made of cardboard, size by size. Obviously, they will be much simpler than patterns for woven clothing. The knitted panels will be stacked on the cutting table and, if necessary, fixed with clamps. The cutting will be done with manual cutting devices i.e. band cutters, electric knives or scissors.

Cut & sew items will be sewn with safety stitch machines featuring an elastic chain stitch and an overlock seam. Usually, a bulky polyester sewing thread with high elasticity and good coverage of the selvedge will be used. Of course, the needles should have a rounded tip.

Fully fashioned panels would be linked mesh by mesh with a circular linking machine (also: dial linking machine) using an end of the knitting yarn – a work which needs a lot of training and experience, especially on fine gauges: the worker has to place loop by loop on the machine hooks. It’s a sign of quality workmanship. All seams, shoulder, armhole, neck, plucket, arm and side seams will be closed with the same machine.

Generally, the linking machines are circular and will match the gauge of the knit. Among the leading suppliers are KMF, Germany, Exacta, Italy, and several others, mostly Chinese suppliers, offer circular linking machines. Characteristics of the machines are double or single chainstitch, dial rotation clockwise or anticlockwise, the number of needles/inch and – as a reference – the corresponding flat knit gauge. The speed can be up to 1,500 stitches/min. Marui, Japan, offers the flat type of linking machine for the long and straight side, sleeve or front seams. Of course, also this type of linking machine is offered in gauges from 3 to 20.

An alternative, quicker and cheaper, are mock linking machines. These flat bed machines simulate the chain stitch, which will be executed with an end of the knitting yarn. Obviously, the gaugeof the knit will influence the stitch length, the sewing thread tension and the choice of sewing needle. A typical machine is Quasar, made by Exacta, presented at IMB 2009 in Cologne – the linking machine of Erbe, France.

Interlining is used only on very fine – 14gg and higher – knits in order to stabilize plackets, double layer collars or pockets. Most of the suppliers have elastic soft interlining featuring ample gluing dots and slits.

A rather new application on flat knits is taping. The technology is used for waterproofing seams and on fine circular or warp knits for active sportswear, swimwear and lingerie. Stoll has run a series of tests lately with Italian Framis, a supplier of thermo bonding devices and materials. Rolling edges, seams, plackets and lapels can be stabilized with the elastic siliconed bands and cut pieces. The thermo bonding is done at 120oC and would be washable with 60oC – which is more than sufficient for knitwear.

Button holes by machines can be quite a problem on coarse knits, as the stitches must be as wide as possible to catch the cut knitting thread. A solution will be knitted button holes.

Finishing after knitting

The yarns for knitting often have a special treatment to ease the knitting process. This treatment has to be removed by washing. The yarn will become fluffy and soft. An additional process after the sewing/linking is the relaxing and forming of the finished item on up-steam tables.

Garments are frequently finished in a partially made-up state, for example, as body-sleeve combinations without neck trims or as garment blanks with separate neck ribs, pockets, etc. The reason for this is to eliminate relaxation shrinkage, which may differ between the components of the garment. In some cases if garments are linked or made up prior to finishing, then the differing relaxation shrinkages may cause puckering. Trims, which are to be wet finished, should be bagged in either polypropylene or polyester mesh bags.

Finishing of wool knitwear can be normally classified into two categories; these include “Wet Finishing” with water and chemical additives and “Dry Finishing” with steam. The latter is sometimes referred to as a “Steam Finish only”. There is a third type of finishing route, called “Solvent Finishing”, where instead of using water, the knitwear is finished in an industrial dry cleaning machine using an organic solvent. However in the wool finishing industry, generally this is not so common practice.

The wet finishing: In the case of woollen spun knitwear, often made of Lambswool or Shetland wool yarns, and the need to remove significant amounts of processing’s oils from the garments, it is essential that the wet finishing route is carried out. In addition in order to obtain the characteristic raised and fuzzy surface, at the same time developing an improved handle, prolonged washing, or an additional washing stage known as milling is carried out. This is conducted by the controlled washing in warm water containing detergent of the garments or knitted pieces in an industrial washing or knitwear finishing machine. Following this the garments are then hydro-extracted, tumble dried before steam pressing.

In the case of worsted spun knitwear, which are often made from fine Merino wool yarns, there is the option as to whether to carry out wet finishing followed by steam pressing, or just to carry out steam pressing alone, i.e. dry finishing.

With the exception of side paddle machines, which are often used in addition to finishing for the piece dyeing of knitwear, most wet finishing machine used for wool knitwear, are based on a rotary drum, rather like a big version of a domestic rotary drum washing machine. In addition some of the more modern machines are combined washers and extractors; this saves the garment having to be unloaded, and loaded into a separator hydro-extractor prior to tumble drying. In practice wool knitwear can be wet finishing in each type of machine, but it must be remembered that firstly in comparison to knitwear made from cotton and man-made fibres etc., that wool and knitwear made from wool can be regarded as being delicate, and can more easily suffer from mechanical damage (holes, seam slippage, etc.) during the wet finishing operation. Secondly, with the exception of say machine washable or Easy Care wool, wool has a unique and natural tendency for felting to occur, which can result upon overfinishing.

The most important chemical used in the wet finishing process is the water. For optimum results the water should be clean i.e. crystal clear, and be extremely soft. simply involves blowing steam through the fabric while it is under minimal tension in order to relax it. The advantage of dry finishing is that in comparison to wet finishing, it is rapid and less expensive. The disadvantage is that it does not allow for the possibility of an anti-cockle treatment to be carried out, or much scope for further modification to the fabric handle i.e. application of a softener.

For dry finishing of knitted fabrics a number of purpose built finishing machines (Novakust, Bisio, Montirama, etc.) are available. Although these machines are primarily designed to handle fabrics in roll form, such as those produced on circular knitting machines, certain manufacturers supply attachments to enable garment panels i.e. fully fashioned knitwear, to be finished. Alternatively, knitted panels can simply be dry finished on a press, by adopting the basic principle of blowing steam through the fabric to fully relax it, then pressing the fabric to set it in the relaxed state.

Embellishment Value Addition

Knitwear can be printed, flocked and embroidered. These processes will be executed on semi finished items or on single panels. Allover and placed printing by screen printing or thermo transfer printing could be done in most cases, best on fine, plain or reverse knit. Fluffy yarns will create problems while printing by obstructing the mesh of the screens and coarse or strong 3D structures will create funny results, as the print remains on the higher parts and will not penetrate to the lower parts of the structures. Shima Seiki has made some experiments with inkjet printing on knitwear using printing heads which move also in vertical direction.

Flock could be stiffening the knits, if the flocking glue is thick and the surface flocked large. It will be best on plain or reverse knit areas.