Price and sustainability have always been key concerns for any developments in the technical textiles sector. The evolution of the wearable electronics reflects the same. Discussed in this article are the real innovations, some of which have been recognized by the Techtextil and Avantex Innovation Awards. Our Special Correspondent, Europe, Claudia Ollenhauer-Ries, reports.

Evolution of Wearable Electronics

The hype on wearable electronic ebbed away, somehow. Of course, important players continued to bring out the latest application examples and further developed devices and components. So did the design company Diffus from Denmark, with the solar cells and LEDs implemented in textiles and controlled by motion sensors. New types of luminating textiles could be designed.

Philips Research, Eindhoven from The Netherlands came up with an emotion vest. The vest can create physical emotions like chill or feeling fast heartbeat of the protagonist of a film for the person wearing it. A net of high-end sensors makes it possible.

Proetex from Italy uses sensors for the monitoring of body functions of fire workers. The sensors send signals to the external supervisor. With this information, the supervisor can help the fire worker to get out of risky areas or send help immediately.

The sensing shirt of Smartex from Prato of Italy, sends information of the body functions via bluetooth technology to a remote “black box” storage system.

Looking for Novelties

Real innovations are rare, but these new products and technologies qualify.

Solving the current problem of counterfeit

Among the novelties is the DNAtex, a development of Schoeller Technologies, Sevelen from Switzerland, which identifies the product and its unique design. With this textile finish, one can detect a copy with an infrared scanner within seconds through a signal. This “textile DNA” is suitable for the whole spectrum of the textile manufacturing chain – thus for chemicals, fibres, textiles and finished products such as clothing or bags. Apart from the financial aspect of counterfeiting, says Hans U. Kohn, COO at Schoeller Technologies, there is the product liability, which is very important for all personal protective equipment. At Schoeller they said, they weren’t aware of the similar development at the sewing thread supplier Amann, Boennigheim in Germany, who presented the “Blue Sky Technology” at IMB 2009 for the first time. The first fabrics with DNAtex will be marketed by the end of 2009 with selected partners.

A problem is the visibility of fire workers in the dark or dense smoke

Up to now the flame and heat-resistant fibre Nomex was only available in filament dyed versions, which are not very fast to light in general. One of these suppliers of standard and customized coloured Nomex is Moulinage du Solier, Dunieres of France.

Bright luminous orange on modacrylic fabrics were shown at Concordia, Waregem in Belgium. The new Flamacryl range is expressly not intended for fire fighters but for industry worker who can come in contact with fire.

Ultrasonic cutting and welding usually requires two different machines, which represent a high investment

KSL Group, Lorch of Germany has for the first time ever come up with a new ultrasonic machine KL 213 for cutting and welding. As Dieter Schaetz, Sales Manager at KSL Group, explains, the machine is for universal use and can be fully integrated into the customer’s making-up line. The machine can be manufactured to measure, with flat bed, short or long arm, post- and free-arm design. Main features include the high speed welding (up to 17m/min) and cutting (up to 12m/min), 30kHz, a variable transportation and the storage of customized production programmes.

The physical endurance and wellness are a great topic for all and quite a lot of fibres and finishings promise both

A really astonishing effect offers the GOLD Reflect’ Line, presented by HT Concept, Gerardmer of France. The bioceramic complex, a Solares technology by RESCOM, is applicated on a polyurethane film placed on the fabric. It is designed to bundle the far infrared parts of the light which are said to enhance the body functions. Medical studies would have proven the beneficiary effects of the bioceramic layer in garments. Thiery Heim, CEO of the company, reported, the French Mulliez-Flory, a workwear specialist, a retail giant, Damart, will launch the first garments during fall 2009. Other applications would be sports, geriatrics and functional rehabilitation.

Examples of Highly Engineered Technical Textiles for Garments

The following examples highlight some of the manifold topics on which the R&D departments of the companies have worked during the last few years.

The examples were picked out to show the wide spectrum of applications.

Safety Rules with Glowing Textiles

The high-tensile schoeller-dynatec fabric by Schoeller Technologies is suitable for work protection or fashionable shoes as well as for interior textiles and upholstery. The “glow in the dark” effect of the textile with filigree 3-D mesh structure comes into its own as soon as dusk falls as the special yarn worked into the fabric absorbs the light it is exposed to, and then emits it in the dark. Like most other Schoeller fabrics, it conforms to blue sign, the most stringent ecological standard for textiles world-wide.

Body Temperature Management

Hexonia, Nettetal of Germany has further developed its ventilation shirt SWOUT, which they had presented at Techtextil 2007. The ventilation system is now small and very light (under 500 grams) and can be integrated into protectors or worn under protecting shells. It is designed to improve the micro climate between the skin and the clothing layers by active air ventilation. The Swiss EMPA approved the effectiveness of the device. Applications could be extreme sports and personal protective garments.

Protective Clothing Materials

ContiTech, Hanover of Germany has developed its protective clothing material further with the new ContiBarrierSystem®. When used in chemical protection suits, the new material design offers much greater protection from chemicals and gases. Hazardous substances such as chlorine, chlorinated hydrocarbons and ammonia are unable to penetrate the barrier layer.

A high resistance to acids, lyes and aggressive chemicals, together with an excellent tear resistance, guarantees the highest possible level of safety for the wearer. At the same time, the material is around 30% lighter at 450 g/m² instead of the usual 700 g/m², and thus much thinner and more flexible than previous materials. This wouldn’t just make it easier and more economical to work and process the material; it also could increase the comfort for the wearer, meaning they can now move better and for a longer time.

Dow Corning pushed the development of the Active Protection System (APS) based on a 3D spacer fabric, presented in 2006-07. Supplied on rolls in textile form, APS is based on silicon materials which are able to absorb and dissipate impact energy thus reducing the amount of force experienced by the wearer. Unlike traditional hard armour, APS technologies focus on providing the comfort. The new line S-Range has three different types of 5 respective 7 mm thick spacer fabrics, to be cut and sewn into garments.

New Sun Protection Finish

Too much sun ages the skin, causes sun burn or, in the worst case, melanomas. Particularly unpleased in this connection are dark colours that reflect neither the visible nor invisible rays of the sun. Schoeller Technologies took these negative aspects as their basis when developing the Coldblack textile finish in cooperation with the Clariant Chemical Company. Coldblack technology is used to treat textiles and directly influence the absorption of heat rays through an invisible colour change. Additionally, the fabric then offers more protection against UV rays (at least UPF 30) without causing any change in the feel or look of the material. Moreover, this new textile finish is permanent, i.e. it does not lose its effect after washing, and can be used on all textiles.

The product attracted great interest soon after being officially launched in August 2008. Coldblack is currently used in the outdoor, motorcycle, golf, cycling, swimming, running and work wear segments. Among the brands are Hugo Boss and BMW motorcycles. “Additionally, we have also carried out initial tests for seat covers and the results have been very promising. Heat management is a topic of great interest in connection with a wide variety of textiles that are subject to direct sunlight.” says Kohn.

Fabric Protection against Dirt

Protective clothing generally has a hard life, gets dirty and has to be washed time and again. Thus, textiles also need protection to ensure durability and comfort. Trans-Textil, Freilassing of Germany, one of Europe’s leading companies is in the fields of lamination, coatings, printing and special finishing for functional textiles. The company presented four new products in accordance with the Oeko Tex 100 Standard at Techtextil 2009. One of them is called Topaz dual guard, a finishing agent that protects garments and, according to the manufacturer, doubles the service life. On the one hand, the fabric thus treated is resistant to water, oil and dirt. On the other hand, contamination caused by oil or graphite could be washed out completely. Hence, Topaz dual guard could ensure that protective clothing in accordance with EN 471 remains highly visible, longer and that products made in accordance with other personal protective equipment standards continue to meet these standards longer.

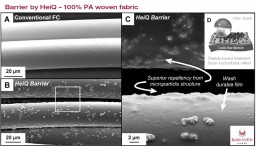

Barrier by HeiQ is a novel particle-based water and oil repellence system based on metallic silver, providing “extraordinary protection against the elements and stains for all types of fabrics”, as the supplier HeiQ claim. The superior performance would be possible thanks to the unique 3D structure of the textile surface built-up by specialized micro sized particles that are firmly embedded in the textile finish applied to the textile. The surface mimics the so-called Lotus effect. The high performance of the technology could also cut the use of fluorine based repellence chemicals by up to 60%, making Barrier by HeiQ an environmentally responsible performance choice. “Barrier by HeiQ offers a completely new dimension to functional finishing with conventional fluorocarbons and other particle-based repellent systems available on the market today,” says Kristofer Skantze, Head of Marketing and Sales at HeiQ.

Conclusion

This Techtextil was a success for all parties, also for the future users, because many developments progressed from the experimental or small scale stage to the production and commercialising stage. Even if the “wow!” was missing, the solutions presented at the show were promising both in the sense of usability and commercial success.