Curtains, one of the major contributors in the home textile segments has witnessed simultaneous growth in the demand with the increase in single family homes during the last century. The global demand for curtains has seen a climb over the last few years, particularly in the Middle East. While the traditional markets are seeing stable growth in curtains of around 3 per cent, the sector in Qatar and Oman has recorded a significant growth for the year, up 91 per cent to US $ 1.15 billion and 125 per cent to US $ 0.27 billion in 2012, respectively; Kuwait has recorded the highest market growth, from US $ 0.19 billion in 2011 to US $ 0.65 billion in 2012, making the region a huge potential base for the product category. The main reason of the growth in the region is believed to be the increasing awareness to the concept of home decor, with women more involved in interiors.

iddle East being a ‘rich’ market which can still afford to spend on luxury, is investing in curtains which are more stylish and luxurious, making velvet the most admired choice of the majority. This subsequent shift is being witnessed globally as well, where the buyers’ preferences have shifted from the traditional cotton and linen to velvets and other blends and man-made fibres. Initially being used for upholstery, bed covers, and cushions, velvet has gained most popularity in curtains and although, velvets are one of the most expensive bases for curtains, with the luxury market on the rise these curtains are seeing good demand.

Today, a lot of manufacturers are making curtains with velvets made of a variety of man-made fibres, such as rayon and polyester, velveteen, velour produced from cotton and polyester and cotton velvet. While they are not as common as polyester and cotton curtains, velvet curtains are available in countless varieties of colours, textures and styles in the market these days; giving further impetus to the trend in home textiles.

[bleft]Gone are the days when a window dressing was sold merely on its functional specifications, today the design, style and material are all key considerations kept in mind when shopping for curtains. [/bleft]

Although, Signature black, sand, sheer white, Caribbean blue, maroon wine, lichen green and burgundy are the most popular hues of velvet drapes, there is a vast range of colours being manufactured.There is a huge demand for dyed, printed, embroidered, embossed as well as solid velvet curtains in the market.Usually the designs available in the market work with a single hem for easy maintenance and have zigzag, herringbone or over-locked edges to keep them from fraying.

Gone are the days when a window dressing was sold merely on its functional specifications, today the design, style and material are all key considerations kept in mind when shopping for curtains.

With the change in the fabric bases of the curtains, other specifications have changed as well, where the traditional width of curtains used to be 137 cm, the modern curtains these days are usually more than 300 cm, especially the sheer ones.

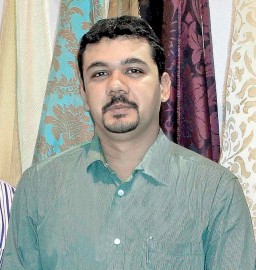

One of the companies working on the niche is Mumbai based Sanchi Velvets, exporting its curtains to the Middle East, the US and Europe, the company offers the segment an extensive array of velvet fabrics, which includes plain velvet, crushed velvet, cotton velveteen, pigment printed velvets and devore/burnout velvets for curtains. The company has a production capacity of 2,00,000 metres per month at present and is operating at 60-80 per cent with the growing market demands for the fabric.

“What started as a niche for us at the time of establishment has turned out to be our USP. As people are appreciating velvet as a base, we have shifted and changed our traditional approach of manufacturing with time and are doing more customized products now for the home textiles. We got into the business with just weaving, but today moving along with the demand we are manufacturing bulk orders for dyed and printed velvets for home furnishings, especially curtains,” shares Kapil Shorewala, Owner, Sanchi Velvets. The company dealing with the home textile fabrics claims to deliver an interesting line of upholstery fabrics in about 12 to 18 months.

Along with velvet, other manmade fibres are also gaining popularity for curtains. “With the price points for linen and cotton products going up, both buyers and consumers are shifting towards more reasonable options and so the demand for the 100 per cent polyester and polyester blends has also gone up. “Looking at the demands and times, we have also shifted our production base for curtains to manmade fibres,” reasons Rushab R Batavia, Head of Marketing, Batavia Exim. At present, the company is working on polyesters with Lurex, 100 per cent polyester and jacquard fabrics as well.

Sharing similar views Ubeyy Lokhandwala, CEO, Furnishing Centre informed, “We are working with the UK market at present for our curtains and from what I have noticed, special fabrics such as bubble fabrics, crushed, techno and jacquards are working better than cotton and linens for the product category and are in demand as well. Also as ring patterns in curtains are becoming more popular, the medium weight blends and the light weight manmade fibre fabrics help the movements of these curtains, making them a more desirable.”

Though a lot of companies have shifted their base to manmade fabrics, there are still some who continue with cotton as the base fabric though they have increased their product development to give innovation. One such company, Vinod Textiles, which works with 100 per cent cotton as their base, is trying new weaves, colours and patterns in cotton fabric in an attempt to sustain the changing demands in the curtain market. “I agree that there is an evident shift in the demand of the fabric base and the price of the cotton yarns has affected and increased the price of the end products, but, still we are hoping to get new buyers with our designs in cotton by moving up the value chain with new concepts,” concludes Jayapalan, CEO, Vinod Textiles.