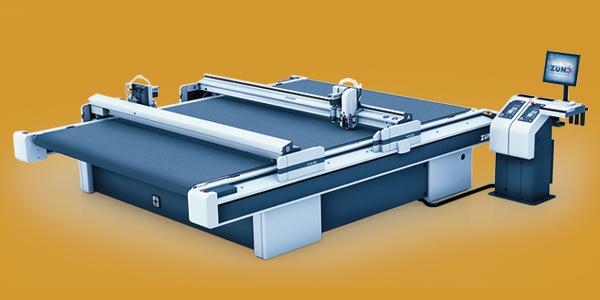

Zünd Systemtechnik AG, a company specializing in developing and manufacturing digital cutting systems for garments, leather, technical textiles and composites among other products worldwide, has developed Zünd D3 cutting system, which offers superb cutting accuracy across the entire working area while doubling the throughput.

The new machine has significant edge over its predecessor, G3 due to the series’ dual-beam construction, where twin beams operate independently and simultaneously in an efficient production workflow, and have up to three different tool modules, which will result in twice the throughput of the single-beam system.

Also Read – Laser Cutting machines are in demand

“Our digital cutting solutions contribute significantly to overall productivity increases; however, just as importantly, the trend towards automation involving different phases of production also demands seamless data flow. By combining the new Zünd D3 ultra high-performance cutter with Zünd Cut Center – ZCC software, we can offer obvious added value to customers looking to make their production both more efficient and more profitable,” says Lars Bendixen, Product Manager Graphics, Zünd.

The precision of the system’s direct drive motor, combined with state-of-the-art software and controllers, guarantees the highest levels of productivity and profitability. The D3 cutter integrates seamlessly in any existing production environment and brings with it a clear competitive advantage in markets that demand the ultimate in terms of performance.

With a flawless, end-to-end digital production workflow, the system delivers unrivalled productivity and performance, making it a perfect match for high-volume industrial production environments.