There is so much more to curtains than what meets the eye. With each and every seam and drape of the curtain visible to the viewer, the tolerances are nearly negligible. Moreover, the challenge of voluminous material handling inevitably follows. The critical issue of material handling while sewing has been tackled in the past with long-arm sewing machines, but material handling during finishing continues to remain a tough turf as barely any significant curtain finishing solutions have emerged in the past. Resolving these set of shortcomings, Eisenkolb, a Netherlands-based curtain processing specialist and a pioneer, offers a wide gamut of solutions for inspecting, cutting, sewing and finishing curtains. Team StitchWorld analyses…

Unlike several other machinery providers who offer either sewing or cutting or finishing solutions, Eisenkolb’s wide range of curtain processing solutions include machines for carrying out processes of sewing, binding, cutting and pressing of all types of curtains. Instead of long-arm sewing machines for sewing large volumes of fabric, Eisenkolb’s machines have sewing heads of leading sewing machinery manufacturers, like Brother, Pegasus and Duerkopp Adler, in combination with in-house developed advanced automats that de-skill the operation. Eisenkolb’s range of curtain processing machines are available in India through Viable Central Asia Exim Pvt. Ltd. (VCAEPL) for the past 6 years.

Eisenkolb began its journey as a curtain specialist for its home country, Netherlands, in the 1990s and slowly took on the European and North American market to expand its business avenues. Like most of the sewing trade, curtains have since then moved to Asian countries for mass production. In the recent past, the segment is not only popular for shipments to western markets but is also becoming a niche area of interest for local markets. India too is catching up fast on high-end curtain requirements for hospitality and home sector with immense focus on quality.

Satish K. V. Nair, Director VCAEPL was so impressed with the technology after seeing it at an international exhibition some years ago that he went on to invest in some machines and today Eisenkolb has an assembling unit in Bangalore, under his tutelage. “Major number of hotels that have come up in the past 2-3 years in Bangalore, have curtains done on Eisenkolb machines,” says Nair proudly. He adds, “We are getting many enquiries from builders and private home makers for our solutions and this clearly indicates that India is ready for this technology and the prospects are only going to grow.”

The potential of growth is huge and Eisenkolb’s fast progress in the Indian market can be attributed to Eisenkolb’s strategy of working with local representatives, asserts Hans Vernooij, Director of Sales & Marketing, Eisenkolb. “We are market leaders in our segment in Europe and America, but relatively new in this region, with more and more end-users willing to pay for high-end curtains we see the market for customized solutions increasing,” adds Vernooij.

Analysing the range of solutions from Eisenkolb…

Inspection & Cutting

CCS-2300: Fully automatic combined fabric inspection, measuring and cutting machine

CCS-2300 is a versatile computer-controlled machine for inspecting, winding, measuring and cutting fabrics on rolls. The machine has a large and illuminated folding inspection window measuring 360 cm x 50 cm and a continuously variable unwinding speed up to 0.5 m/s. The spindle motor on supply box is sensor-controlled for optimal edge guiding for accurately unwinding fabrics. The machine can also perform laser-guided pattern alignment inspection. The servo-driven double-acting round cutter can cut fabrics of width up to 340 cm. The inspection stops automatically at the end of the program or at the end of the roll and an error database for inspected fabrics is maintained.

Sewing

ACP-2200: Automatic combined panel joining/tape attaching machine for curtains

Equipped with a Brother high speed 2-needle, 4- or 5-thread EXT-series of variable top and bottom feed safety stitch machine, ACP-2200 has an auxiliary puller feed and an in-line belt feed that offers excellent, pattern matching, sewing results in panel joining operation. The combined top and bottom feed facilitates fast and smooth buckram tape attaching. The sewing table has a fully synchronized 550 cm-long conveyor belt to simplify the handling of large and heavy curtains. Advanced pneumatic fabric guiding system, optional with separately adjustable upper/lower layer guides, offer quick and flexible adjustment to differences (up to 50 mm) in selvedge. The sewing unit is extendible for easy threading, cleaning and maintenance. The start/stop functions can be controlled by means of pulling cables situated along the entire operator side of the machine. Since ACP-2200 has a fully automatic PLC-controlled autonomous sewing sequence, the operator’s task is only limited to loading the curtain panels to the presser foot. This results in a consistent high quality and high output volume.

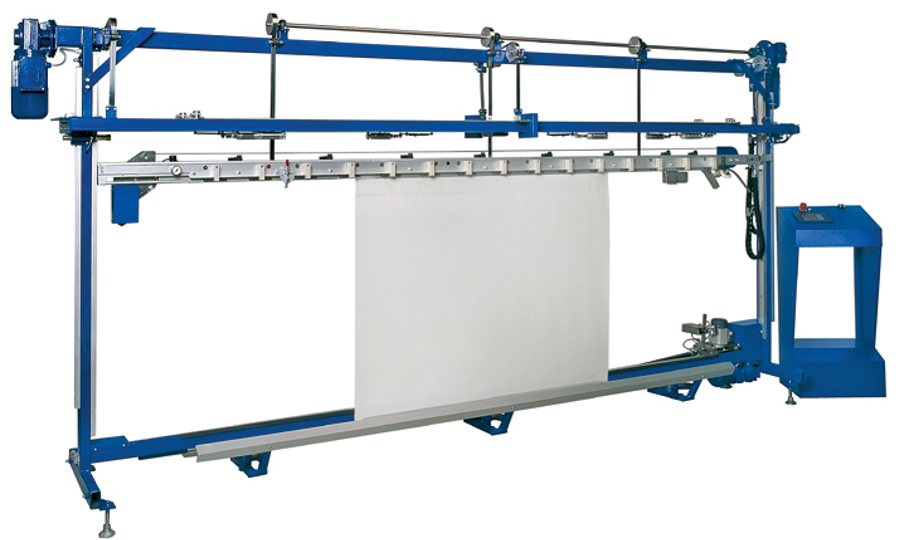

AGA-2300: Fully automatic, programmable vertical curtain end-cutting device

The machine comes with a triple lifting beam to attach the curtain by means of springy clamps via a rod through the lower hem or by the lead cord bar using the curtain’s bottom lead cord. The operation can be programmed through the multilingual dialogue LCD touchscreen for feeding the cutting height and the seam allowance. The machine is available in two versions – Model 2300DP for workrooms with maximum height of 600 cm and maximum width of 1135 cm; and Model 2300DPX for workrooms with maximum height of 600 cm and maximum width of 900 cm. The machine is available with a large number of options, such as triple lifting beam with pneumatic clamps instead of springy clamps, triple lifting beam with extended pneumatic clamps for lined curtains, fully automatic UV ink marking device for curtains, blinds and shades, and double rod system for the simultaneous cutting of face fabric and lining. The machine is useful for cutting unlined curtains.

BCP-2200: Automatic blind stitch curtain hemming machine

Equipped with treasure single-thread chainstitch blind stitch machine, BCP-2200 has a 550 cm-long conveyor belt for simplifying the handling of large and heavy curtains. The machine is equipped with two multifunctional air injection hemmers to obtain a perfect 100% turn of double hems up to 120 mm, even when thin and transparent fabrics are processed. What makes the machine extremely versatile is that both, double and single hems, can be made by the same hemmer. Like the whole range, the sewing section is extendible for easy threading, cleaning and maintenance. An extended puller to process lower hems up to 180 mm is available as an option. As each unit of BCP-2200 has only one sewing head, an operator can handle two machines in tandem and control of start/stop functions by pulling cables, situated along the entire operator side of the machine. Since, BCP-2200 has a fully automatic PLC-controlled autonomous sewing sequence, the operator’s task is deskilled to simply loading the curtain panels to the presser foot. This results in a consistent high quality and output volume.

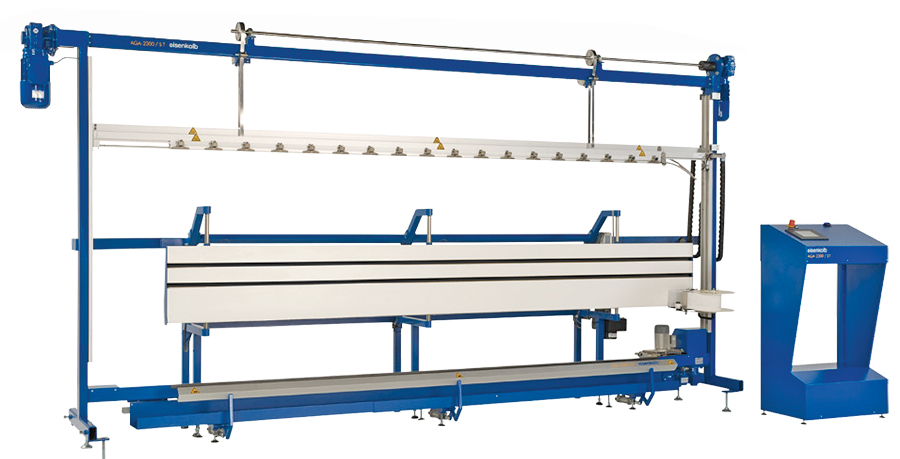

AGA-2300/ST: Fully automatic final height cutting and top finishing machine

AGA-2300/ST has two independent lifting beams – one beam is for inserting the face fabric and the other beam is used to insert lining. Both beams can be set to cut different heights simultaneously. Any desired clearance between lining and face fabric can be set. Eisenkolb claims to cut stretchy fabrics as well with utmost accuracy through this machine. The machine is equipped with an easy-to-use buckram dispenser to unroll buckram tape and adhesive. Table surface is also equipped with brushes to tack 4’’ top.

ATS-2400: Pocket stitching machine for Roman blinds

With a Duerkopp Adler single-needle post bed machine with reversible top-driven roller, ATS-2400 sews the pockets of Roman blinds. Pockets with a tunnel depth between 10 mm and 30 mm can be sewn by the machine. Equipped with synchronous servo motors, and lifting beam with pneumatic clamps, the machine can produce 80 high quality Roman blinds in eight hours. The sewing table is 4.45 m wide and 6 m high which basically offers the ability to manufacture one large or multiple small blinds in a single run. The machine also comes with a provision of UV-marking unit for the simultaneous marking of rings or pockets/ring tape.

CCP-2300: Automatic lockstitch curtain hemming machine

CCP-2300 has a high speed single-needle lockstitch machine with adjustable top/bottom feed and intermittent puller feed and a fully synchronized 550 cm long, conveyor belt for improved material handling. With two multifunctional air injection hemmers, turn of double hems up to120 mm can be achieved, even when thin and transparent fabrics are processed. Both double and single hems can be made by the same hemmer. Like the above mentioned models, the sewing section is extendible for easy threading, cleaning and maintenance and the operator is only required to load the fabric panels to the presser foot, facilitating high quality output and productivity. An extended puller is also available to process hems up to 180 mm. Other accessories include edge guide system to sew tunnels in blinds and shades and quick exchangeable pneumatic fabric guidance system to convert the machine into a pattern matching panel joining machine.

COMBI series

What truly sets apart Eisenkolb’s machines is the conveyor belt table. Understanding the same, Eisenkolb allows its customers to choose a combination of sewing heads (safety stitch, blind stitch, single-needle lockstitch, 2-needle lockstitch and multiple-needle chainstitch) to suit the requirements of the products being manufactured by a factory.

EPS-2200: Electronic, pre-programmed, straight line lockstitch pinch pleat tacker

EPS-2200 sews using a versatile Brother BAS-311H sewing unit, pre-programmed to process 2’’, 3’’, 4’’ and 5’’ Microflex adjustable curtain hooks. The machine has a separate spot-tack programme to fasten (manually) folded double and triple pleats, an adjustable guide to set pleat depth and a fully automatic curtain hook feeding device with automatic adjustment of the hook height (header) between 5 mm and 50 mm in steps of 5 mm. The machine is modified to include a large Microflex hook container which can store up to 100 hooks. EPS-2200 can produce up to 2,500 single pleats a day.

MPS-2300: Fully automatic programmable curtain pleating machine

MPS-2300 is designed to execute all steps in the pleating process such as pleat calculation, machine setting, pleat folding, hook feeding, pleat stitching and pleat tacking. Equipped with a Brother BAS-311H sewing unit, the machine is pre-programmed for the production of single and double pleats with embedded Microflex curtain hooks in the length of 55 mm, 75 mm, 95 mm and 125 mm. The pleat depth is adjustable from 20 mm up to 50 mm; the pleat distance is adjustable from 65 mm up to 185 mm. Besides, an accurate low capacity line laser always guarantees equal pleat distances. The machine can produce up to 2,200 butterfly pleats a day.

PPS-2300: Fully automatic curtain pinch pleating machine

The best-in-class, PPS-2300 can produce 1,800 pleats in an 8-hour shift by applying advanced pleating techniques, a wide range of double and triple pleats can be produced in a wide range of curtains – from net curtains to heavy lined curtains (up to 20 mm pleat thickness). The software has a help function for the complete process. The worldwide patented seam positioning system guarantees the highest quality in finishing, because of the fact that the seam can be positioned wherever you like in the curtain. Just think of a seam only a few ‘mm’ away from the pleat, making it almost invisible. Any pleat depth between 17 mm and 40 mm, and any pleat distance between 80 mm and 180 mm can be achieved. The maximum pleating length is 99.99 m. Moreover, if connected to the internet, the machine can be fully read out from a remote location, reducing the downtime to a minimum.

Finishing

Deko-2000: Professional curtain ironing table

The machine comes with a large electrically heated ironing surface measuring 280 cm x 60 cm. Deko-2000 has a rotating ironing surface, which can be moved forwards or backwards by means of a foot pedal, for the effortless transport of an ironed curtain. The ergonomic construction of an ironing surface is ensured with a 6-degree angle and a weightless hanging/guiding of the iron prevent fatigue and MSDs. Moreover, fabric troughs at the front and back of the table prevent contamination of the curtain by contact with the ground. The installation is completed with iron hanging device, balancer for the weight compensation and ironing surface fluorescent tube lighting.

Hyproflex: Hydraulic combined cutting/pressing machine for processing metal curtain rings

The Hyproflex is equipped with two hydraulic dual-hand operated cylinders (one for cutting and the other ring pressing) for simple and accurate pressing of eyelets in the curtain. The distance between cutting and pressing tool is adjustable from 80 mm up to 230 mm. The machine allows quick changeover between knife and punch options.

Fanfolder: Fully automatic vertical curtain ironing and finishing machine

Fanfolder is a curtain finishing machine to obtain consistent and regular pleats that retain their shape. The temperature is adjustable between 150° C and 230° C at an ironing/shaping speed between 0.7 m and 6.5 m/min. The machine has a powerful, time-controlled exhaust for a perfect, dry curtain after the steaming/shaping cycle and an exchangeable rack providing space for 36 pleats.

Consumables

Microflex: Adjustable curtain hook

Microflex, a sewn-in curtain hook for pinch pleats, is a patented Eisenkolb innovation. Normally curtains are hung using metallic pins which are either put on a stitch or through the fabric. If placed on the stitch, the pin can hold only as much as the stitch can hold, and if put through the fabric, the pin holds as much as the fabric can hold. On the other hand, Microflex is sewn in such a manner that all the stitches are through the pin and the fabric. Adjustable in steps of 5 mm, it can bear a weight of 9 kg per hook. It is washable, tumble-drier and UV proof, and is processed fully automatically on Eisenkolb pleating machines.