The use of 3D in the fashion industry is not just a concept anymore! However, it isn’t a concept also that has been given the due respect which it deserves despite hundreds of players being available in the market now who are rigorously talking only about 3D or digital product development process or digital showrooms or, simply put, digital fashion. So, where is the gap? Why is the fashion industry not able to cut costs in time-consuming and complicated processes using 3D and standardise it? Why is it so that the stakeholders are still not preferring 3D sustainable solutions even though they know they can save the environment and boost sales at the same time by opting for 3D?

The solution to all above-mentioned issues is already known to the industry and no scrutiny is needed to deploy it. But, what should be the factor that will catch the nerves of the industry and pave the way for it to adopt digital fashion and UN SDG 12 mandate which is, ‘Ensure Sustainable Consumption and Production Patterns’? The answer is – realisation of the industry about its over-polluting conventional practices. The pollution and extensive rise in global temperatures have collectively pushed the fashion industry to seriously think about transitioning from analog to digital.

Fashion industry has been brutal to the planet and it’s high time to bring technology as saviour…

More often than not, we keep hearing and reading that the fast fashion industry is the largest contributor to pollution and waste. The fashion industry creates 100 billion clothing items in a typical year, and three out of five items end up in waste bins and landfill within 12 months. And all these items are manufactured using 1,000 different types of chemicals, making the recycling process challenging and complex. The bottom line is that the planet is paying a high price for cheap apparel. The rise of e-commerce has made access to fashion and apparel far wider around the world. The consumption of apparels has increased enormously, and with increased consumption comes huge growth in the quantity of clothing that gets discarded.

“Eighty percent of discarded clothes end up in landfill within 12 months,” according to a recent study by BBC Earth. The US $ 1.80 trillion worth of apparel industry has one of the most complex supply chains in the world. These long supply chains are behind the fashion industry’s contribution of 10 per cent of global greenhouse gas emissions, according to recent United Nations research.

Rachel Arthur, a Sustainability and Innovation Consultant, says, “We need something that enables fashion brands to make more responsible sourcing decisions at different stages of the supply chain. Without that, a lot of this is guesswork, or it’s a case of global averages and assumptive results.”

Traditional sample making is NOT sustainable…

One of the reasons for waste and excess emissions in the fashion industry is investments in the sample-making. Sample-making is a complex process that consumes considerable resources, especially fabric. How many of us know that over 30 per cent of the material is wasted during the sample making process? Most of us, right? But, how many of us are ACTUALLY making efforts towards bringing it down using technology? Only a few!

On an average, for a single piece of clothing, there are four to six stages of sample making. When a prototype sample is finally made, manufacturers usually have to create the samples for their buyers in different colours, patterns and fabrics. Most of these physical samples go directly from the factory floor to storage and ultimately to landfill. There are two types of supply chain strategies: Agile and Lean. The agile strategy is flexible and responsive to mass production, whereas lean supply chains are geared towards the customisation market, with limited production runs. The agile supply chain model is the leading cause of excessive consumption of resources, time and money.

Many have suggested that recycling could reduce resource degradation, but unfortunately recycling requires additional consumption and infrastructure for pick-up, transportation, sorting, cleaning and processing. Synthetic fabrics are also made up with dozens and sometimes hundreds of different types of chemicals, which makes the recycling process even more challenging. Fortunately, new technological innovations can reduce many of these adverse impacts on the environment.

Also Read: Lectra’s Daniel Harari on planned acquisition of Gerber Technology…

The Ohzone, Inc. aims at making fashion industry more sustainable via its cutting-edge technologies…

According to a recent research by The Ohzone, Inc., a US-based 3D fashion solution provider, a medium-sized apparel manufacturer that produces 160 SKUs a year uses 912,000 litres of water on an average just to create samples annually. As a reference, 1 million litres of water can meet the needs of 185 people for a year. The Ohzone’s 3DREALTM Technology claims to save more than 700,000 litres of water annually for the apparel manufacturers that is enough to reduce the scarcity of water for a small village in Africa or India. The Ohzone also calculated that using 3D technology to create samples can reduce CO2 emissions from 1,536gm/km to 256gm/km.

So, how does this technology work?

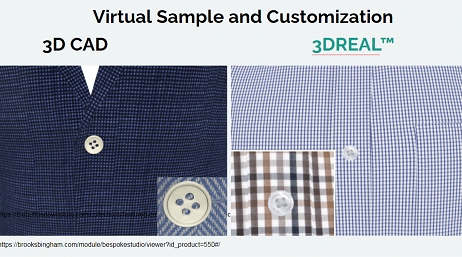

According to Oh Tepmongkol-Wheaton CEO and Co-founder, The Ohzone, the current 3D technology of the company is capable of creating 3D samples with high-resolution imagery and the fashion companies can create samples virtually in different colours and patterns with intensely realistic visuals as physical samples, helping create an eco-friendly supply chain. Virtual reality and augmented reality technology, in conjunction with 3D imagery, can aid businesses that are resorting to virtual showrooms due to COVID-19 and can even help boost sales for fashion brands with interactive experiences and storytelling!

“Depending on the 3D sample process of the brands, a top-of-the-line sample can be so realistic that it can be digitally approved, with no need to ship actual samples at all, thus solving the chronic problem of wasteful one-time samples in supply chain models. With authentic imagery such as OHZONE 3DREALTM, top-of-the-line samples can also be digitised and used as finished product images,” comments Oh Tepmongkol.

The 3D imagery can be used for market testing and can be given or sold to a retailer, just like the imagery of a finished product. This shortens time to market and saves costs on photo publishing.

This is how 3D Real Technology of The Ohzone is different…

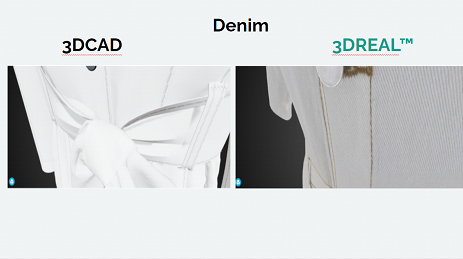

Now the question arises that what competitive advantages The OhZone’s 3DREALTM technology has over its competitors! Oh Tepmongkol states, “With ours (technology), true-to-life 3D model with draping and texture at any zoom level is clearly possible, while in our competitors’ cases, the more you zoom, the more CGI-ish it looks.”

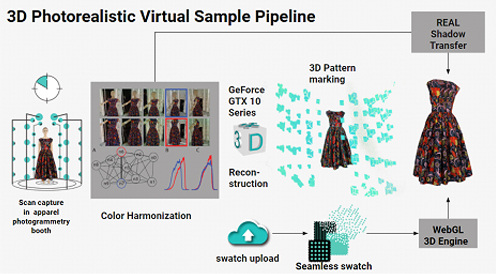

Oh further informed that the traditional 3DCAD software is used for planning, design and product development phase. It simulates texture and draping using ‘fabric equation’ technique. “While we use a photogrammetry-based approach to capture fabric and draping and then accurate project onto 3D model,” shares Oh.

Moreover, the turnkey digitisation solution includes 3D model creation, optimised viewer for mobile and web, configuration tool with seamless integration with most e-commerce platforms.Another advantage is that the technology is able to create genuine real-time interactive model with no extra hardware or software needed at this quality level, not pre-rendered video. “3D virtual samples can replace real samples for B2B and B2C with our Material Magic and Livesync update,” avers Oh Tepmongkol.

The Ohzone also has ‘the world’s first interactive fashion show’ registered on its name…

Having only technical skills, coupled with disadvantaged background, the team had to work with no external funding for the past seven years. Despite financial challenges, the company built the world’s first apparel 3D scanner (as they claim), presented the world’s first interactive fashion show – not a mere video – with SFCFW.org, were awarded two patents, and launched its 3D digitisation service for apparel – an impressive feat given that 3D technology usually requires intensive capital. These patents are – 110,373,386 (System and method for virtually trying-on clothing); and 210,127,717 (System for 3D Clothing Model Creation).

The Ohzone built its scanner in 2016 which is optimised for apparels to capture the draping, texture and colour harmonisation with high throughout. As per the company, the hardware and software are tightly integrated; hence it can digitise 4-6 garments an hour. On the other hand, the 3D scanners built by the competitors of The Ohzone, are designed for hard surface good or human body – geometry, not texture and draping.

“At the current quality of texture and details of the 3D garment, others can only output a pre-rendered video, while we can output a 3D model that is fully animated and can be interacted with in real-time without any extra equipment (like headset or high powered computer),” asserts Oh.

The Ohzone Inc. presented an interactive fashion show back in September ’20 for the closing event of New Era Virtual Fashion Week. This live virtual runway show featured 10 exclusive designs – one each from 10 featured fashion designers. What’s more interesting was that these designs were open for shopping throughout the live show.

The use of 3D technology developed by the company supported the interactive capabilities and the attendees were virtually able to hop onto the runway to stop a fashion model, rotate him/her to inspect different angles of the worn garment.The attendees were also able to zoom in the garment to closely examine its design details like colours, fabric textures and patterns.

“Now we are going to produce 3DREALTM versions of runway looks of international fashion designers along with animation in order to offer attendees the opportunity to shop live on their own terms,” informs Oh Tepmongkol, adding, “At The Ohzone, we aim to democratise 3D virtual fashion and make it accessible to small- and medium-sized brands to help them increase sales, lower returns and be sustainable in the post COVID-19 era. We offer a turnkey 3D digitisation solution that creates high-fidelity, exquisitely-detailed 3D garments from real garments in zoomable, rotatable images in a genuinely interactive self-contained virtual environment and will continue to do so.”

(The article is written with inputs collected by Apparel Resources and information shared by The Ohzone, Inc. team – Oh Tepmongkol-Wheaton, CEO/CO-Founder and Parisha Uppal, Marketing Personnel)