Yupoong Inc. from Korea, with factories in Dominican Republic, Bangladesh and Vietnam, is currently exporting $100million worth of hats to over 60 countries. Offering the trademark Flexifit technology, one of the company’s biggest buyers is MLB (Major League Baseball). Similarly, DaDa Corp., again from Korea, boasts of a global market share of 45 percent with $ 100million export sales each year and factories in countries such as Indonesia, Vietnam, China and Bangladesh. The company’s sports hats are supplied to all franchise teams of the four most popular U.S. sports leagues, namely American football, baseball, basketball and ice hockey for names such as NBA, MBL, NFL and NHL, and the world’s top fashion brands, including Nike, Adidas, Reebok and Polo.

Yupoong Inc. from Korea, with factories in Dominican Republic, Bangladesh and Vietnam, is currently exporting $100million worth of hats to over 60 countries. Offering the trademark Flexifit technology, one of the company’s biggest buyers is MLB (Major League Baseball). Similarly, DaDa Corp., again from Korea, boasts of a global market share of 45 percent with $ 100million export sales each year and factories in countries such as Indonesia, Vietnam, China and Bangladesh. The company’s sports hats are supplied to all franchise teams of the four most popular U.S. sports leagues, namely American football, baseball, basketball and ice hockey for names such as NBA, MBL, NFL and NHL, and the world’s top fashion brands, including Nike, Adidas, Reebok and Polo.

In another part of Asia, the HuaXia baseball cap factory, located at the banks of Yangtze, China, is producing 30 million baseball caps each year. Everyday the factory fills a standard 40-foot container with 60,000 caps that are shipped to retailers across the US and Europe at an average price of $1 (50p) per cap. A sister factory, Hua Yuan, has an exclusive contract with Nike to manufacture their branded caps.

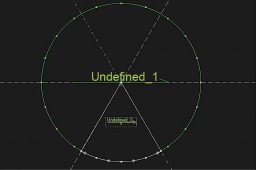

A baseball cap is a soft hat consisting of a soft fabric crown sewn of several sections of fabric and a visor that protects the eye from the sun. Special order caps are made to fit the wearer in specific sizes; however, there are mostly mass-produced models, which have a plastic extender in the centre back that can adjust sizes as per the wearer’s needs.

Baseball caps are generally made of wool, cotton or cotton-synthetic combinations. The visors of these caps always have some kind of stiffening, sometimes it is buckram, and other times it is a plastic insert. Sweatbands may be cotton or even thin leather, depending on the product.

The omnipresent baseball cap, which turns 50 this year, is a favourite with people across boundaries from the young to the old, at work or at play, all athletes sport them. Rock and rap stars jam in them. Politicians love to be seen wearing them. However simple they may seem, designers of caps not only need to keep up on what’s hot and what’s not, they have to anticipate it with options in countless colour and pattern combinations, with fabrics including silk, cashmere, chiffon, denim and snakeskin. The business of making caps is a serious industry.

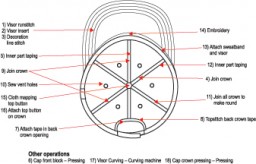

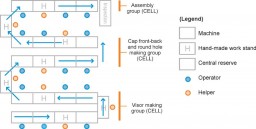

The Manufacturing Process

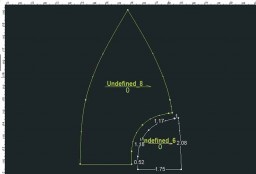

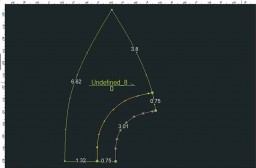

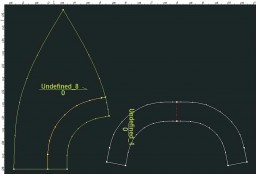

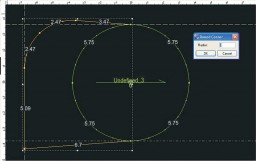

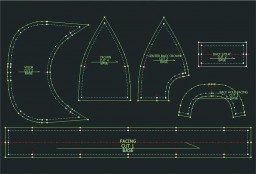

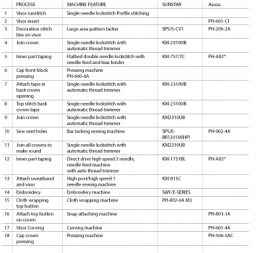

An adjustable baseball cap has a total of 5/6 pattern parts namely crown, centre back crown, visor, back hole facing and sweatband. Apart from sewing machines the manufacturing of cap requires various other machines for ironing, visor curving, eyelet making and top button attaching.

While brands like Sunstar, Juki, Pfaff etc. offer specialised sewing machines for cap making, specialised brands like Asosa and Doory from Korea, and Capableli from China offer specialised pressing, visor curving, top button attaching, cap size checking; work aids and attachments of sewing, etc.

Sewing Operations

Asosa PH-200-2A is for decorative stitching of the visor of the casual and baseball cap. It is simple and easy to store a new design into the diskette. The stitch length, number of stitches, distance between stitch lines and curve of stitch line can be redesigned as per requirement. One worker can handle 3 to 4 machines at the same time.

SPS/S-CV1 series from Sunstar is for decorative stitching on the visor. The direct drive mechanism reduces the noise and vibration significantly ensuring a pleasant working environment. The size of the visor depends on the sewing area, which is 300 mm X 180 mm. The machine is equipped with FDD as a standard, enabling copy of design pattern. Reproduction of design pattern, therefore, becomes easier. The number of patterns that can be stored is 691 and any design pattern can be reduced or enlarged based on grading requirement.

Crown joining at different stages is being done by KM 2310U series single needle flatbed lockstitch machine. Inner part taping at every crown join seam is a very important operation in cap making. Inner part taping is done by KM-757 and/or KM-1751 series of double needle flatbed lockstitch machine. Its needle feeding system ensures neat finish without any ply slippage. The double capacity hook ensures less downtime. KM-1751 is a dry head direct drive technology for oil stain free environment.

Attaching of the sweatband and visor is done by KM-815C series, which is a high post bed single needle lockstitch machine with feed mechanism for shift free sewing.

Ironing/Pressing Operations

Asosa PH-501-2A is an electronic type automatic cap-ironing machine. The machine is supplied hot steam by a heater fitted inside it through a water tank that is installed outside. A cap-cooling device, offered as an optional item, can be installed at the rear of the machine. The machine has an electronic control and is recommended for small quantity production.

Asosa PH-501-5AA is suitable for volume production where 5 moulds are sequentially operated by a pre-programmed microprocessor. All the functions such as steam and ironing time & taking cap out are automatically controlled as programmed. The cooling device is installed at rear of the machine. CAP ironing machinery Gh-Kt-308 from Doory’s is another highly productive machine.

PH-600-4A is a front block-ironing machine. This is for ironing and shaping of the front part of the cap. The machine has 4 moulds and an inbuilt automatic steam sprayer. A mould can be used for shaping the cap front. The machine is good for a large quantity production.

Visor curving

Asosa PH-601-CI is an automatic cap visor-inserting machine after the visor run stitch and turning is over.

Anybody without a skill can insert it very easily and efficiently. One machine can insert both covered and flat visors with only a change in attachment. Around 700 pcs per hour are produced.

PH-601-CC is an automatic visor inside cutting machine. This machine can cut just a single visor at one time and cuts 900 pcs in an hour. PH-601-4A is an automatic visor-curving machine with an inbuilt air conditioner.

This machine presses the visor of the cap to create a curve style after ironing the cap.

It consists of 2 sets of cap visor curving machines, 1 set of cap cooling device (12 holes) and 1 air conditioner. This machine can produce the round cap visor in a short period of time.

Cap Embroidery

Almost every multihead computerised embroidery machine brand offers a baseball cap embroidery mechanism. SWF/E-SERIES machines from Sunstar of dual cylinder bridge type offer an expanded memory size of a maximum of 100 rooms and a basic capacity of 2 million stitches. Designs can be rotated upto 359 degrees and can also be reversed in X,Y axis or both directions. Selected designs can also be enlarged or reduced 50% to 200%.

With a max speed of 1,000 spm, it offers an embroidery area with a broad width cap frame of 360mm X 75mm where even the front and side of the cap can be embroidered. The semi cap frame is more suitable for smaller motifs and has an embroidery range of 180mm X 83mm.

| Machine | Time in | Standard | Operators | Operators |

| Type | Seconds | Allowed | Required | Allocated |

| Minute | ||||

| 1 Lock stitch | 43 | 0.89583 | 3.94001 | 4 |

| 2 Twin needle | 51 | 1.0625 | 4.67303 | 4.5 |

| 3 Upper & lower feed | 87 | 1.8125 | 7.97164 | 8 |

| 4 Edge trimmer | 5 | 0.10417 | 0.45814 | 1 |

| 5 Exclusive m/c | 66 | 1.375 | 6.04745 | 6 |

| 6 1-pattern postbed | 35 | 0.72917 | 3.20698 | 3 |

| 7 Manual work | 59 | 1.22917 | 5.40606 | 5.5 |

| 346 | 7.20833 | 31.7033 | 32 |

AMAYA XT from Melco offers the largest cap-sewing field in the industry. The cylindrical lower arm, the smallest in the industry, gives it the ability to embroider the widest range of caps and visors. The machine also offers the Acti-Feed™ thread tension technology with a speed of up to 1,500 spm and features such as the industry’s first colour backup system where the user can program groups of needles together so that in the event of a thread breakage, the machine automatically switches to the back up needle. It also boasts of providing a laser eye for tracing and positioning of the design.

The CT900 series of embroidery machines from Baishide offer built-in 305” floppy disk driver with the ability to read even Tajima and Barudan designs. Features such as a memory capacity of 2 million stitches, storage of up to 200 designs, automatic colour-change, automatic offset and auto-trimming and the function of setting scale-limit in the software making it more convenient for cylinder embroidery contribute towards rendering the machines quite popular.

Eyelet making

Asosa PH-902-2A is an automatic eyelet-punching machine suitable for small volume production. It is used for stitching eyelet holes in a cap. The operator can choose from a variety of sewing patterns (for example 94, 106, 118 stitches). This has an eyelet pin device, which improves the cap quality and productivity.

SPS/E-BR1201M (HP) from Sunstar is capable of storing 32 basic patterns and 67 additional patterns. The direct drive machine has a maximum speed of 3200spm. Stitch movement is controlled by a micro unit (0.05 mm), thus providing accurate sewing and best quality.

Top Button Attaching

PH-803-1A is automatic top button fixing machine that attaches buttons on cap which can attach about 3 to 4,000 buttons in 8 hours.