Generally garment manufacturing companies face the challenge of multi-style low volume orders and short delivery dates. However, the vast majority of enterprises in the production plan management still uses the traditional spreadsheets for planning. This results in frequent management meetings; 80% of the production time is spent on discussions of the production schedule, program coordination, delivery delays and other issues. In response to this, a garment production plan scheduling optimization system – IOS-APS has been developed by Guangzhou Integrated Optimization Solution Co. to provide enterprises with rich features like capacity load, change orders, material availability, alerts for key preproduction events, and production schedules, to improve timely delivery of goods and reduce excess inventory, while strengthening the communication between the multiple stakeholders and increasing customer satisfaction as well.

In order to adapt to different production management levels (top management, middle management, etc.) and meet the specific practical needs of production, IOS-APS provides three scheduling methods: Automatic Scheduling Optimization, i.e. the use of complex mathematical modelling and operations’ research knowledge to develop the production plan; Overall Multi-objective Optimization: To generate the best overall production scheduling programs; Semi-automatic Scheduling: For scheduling according to the actual needs of the user to select the scheduling rules (such as to meet the delivery priority, the highest priority of production efficiency, automatic demolition of single law, etc.); and Manual Scheduling: According to their own judgment users draw out the schedule manually in the visual scheduling vessel.

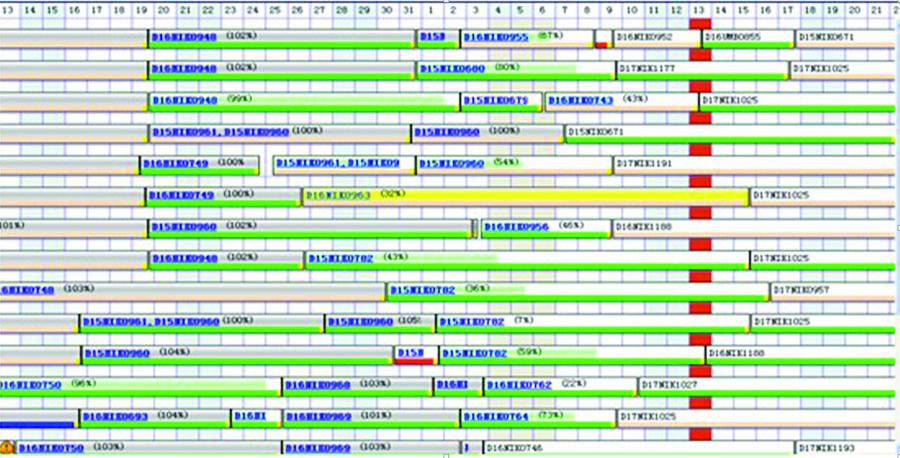

By dragging the mouse, users can easily achieve common scheduling operations, such as shifting a single order, deleting and combining orders and so on. A variety of colours to meet customer’s delivery orders represent various situations, such as red indicates serious delays, blue represents a serious advance, etc. Also IOS-APS permits production order change processing, so that scheduled production plan can be updated in a timely manner. These features of the software help in developing high-quality production scheduling program. Through a task reminder, panel production management staffs are informed about important production updates, especially the non-adherence to the planned work, order delivery delays, late arrival of raw materials, milestone activities in pre-production events, so that appropriate steps can be taken to minimize the losses.

An order can contain multiple deliveries in more than one colour and size when production scheduling of the order is to be carried out according to detailed scheduling. Moreover, when there’s any change in production order information (such as delivery date, number of standard working hours, etc.), IOS-APS can automatically synchronize the corresponding production of a single plan to ensure that production planning and order information are always consistent.

The software also has a Capacity Load Management function, which allows the user to simultaneously consider delivery performance and inventory levels for optimal resource utilization. The software helps pre-empt production bottlenecks, and adjust the use of materials or resources to respond. Temporary production capacity can be created for urgent orders to meet delivery date on the software’s planning board. The software is equipped with artificial intelligence to calibrate the new capacity (original + temporary) against the original to ensure that the effective load on bottleneck resources is within the permissible limits. IOS-APS displays the ‘load’ histograms or detailed list of data which can guide the planner and adjust order’s production capacity.

Order modules that include order management and material management, production schedule management, sewn progress, milestone activity in pre-production, and material procurement schedule are available through the docking system or manual input mode acquisition. The impact of these plans on the production schedule is in the form of colour-change or an icon pop-up on the visual scheduling device to remind the planner, in order to take timely and effective measures. Data connectivity methods can either be a docking system or a file (Excel/ XML/Text) import, it can also be entered manually.

IOS-APS can be integrated easily with traditional information systems, including ERP, RFID, standard working hour’s system, electronic Kanban system, field control systems integration, and information sharing, thereby maximizing the overall effectiveness of enterprise information management.