HeartDub, Chinese start-up, has introduced an AI-based technology to provide clothing samples for manufacturers so as to help them streamline their production process and cut down the product development cost.

The software gathers data on textile materials and creates virtual fabrics that mimic the properties of the real fabric.

With the innovation, the start-up aims to digitise the logistic in apparel industry and provide online solution for the development and selection of textile materials and production of clothing samples.

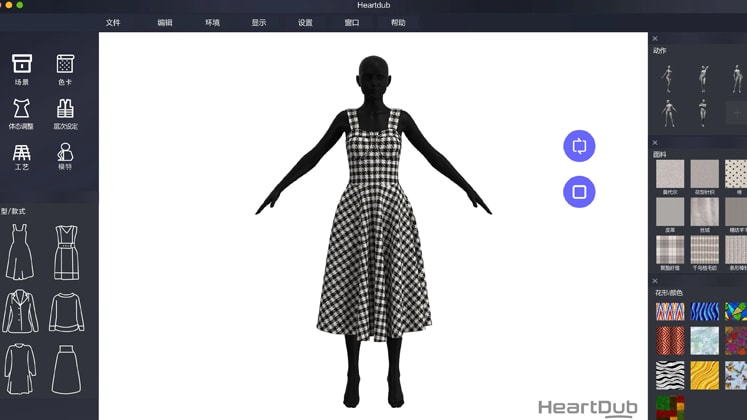

The platform comprises a materials database that contains information on various fabrics, patterns and colours; design images and simulated images of clothes worn by virtual models.

The designs are created by combining the materials in the database and these digital clothes can be put in virtual models. These virtual models are programmed to make various models to show how they would look in real life.

“Virtual fabric-making starts with analysing the structure of actual fabrics and inputting the data into the software, called a ‘physics-engine’, to simulate fabric’s physical properties.

HeartDub’s laboratory already has extensive data on frequently used fabrics. The characteristics of these virtual fabrics correspond to those in the real world, allowing their texture, weight and movements to be accurately simulated,” said Li Ruohao, Chief Technology Officer, HeartDub.

The innovation reduces the cost of developing and designing the fabric in comparision to the traditional method that involves making physical samples and getting approval.

The task not only required extra time, but also involved extra efforts and resources.

Li said “The company’s digital platform allows fabric makers to complete the steps up to preorder presentation at no cost, thereby cutting their overall development cost by about half.”

Li added “Fashion brands also need to make fewer clothing samples because they can see how they will look, thanks to the virtual models. Production costs can be cut by 70 per cent and sample delivery time is shortened by 90 per cent.”

The start-up’s major client base includes fabric makers and fashion brands – where the fabric makers can make textile design and upload that on the platform and where the fashion labels can examine how the clothing will look on the virtual avatar and can make their purchase accordingly.