Selecting the proper thread for denim garments is very important to minimise sewing and seam performance issues. There is an old saying – Thread only makes up a small percent of the cost of the finished product … but shares 50 per cent of the seam responsibility.

A typical pair of adult-size jeans will have threads ranging from 200 to 250 yards in them depending on the seam construction. Most major jeans manufacturers have experimented with different thread types to reduce cost but they have found that corespun threads give the best overall performance. Jeans makers put their products through various wash processes after manufacturing and some of these processes can be very harsh. The cost of these wash processes can be from 75 cents to US $ 3 per jeans depending on the chemicals, stones, enzymes and process time required. The amount of thread used in a jeans typically costs between 25-30 cents, while the wash-process can cost up to US $ 3 per jeans.

Therefore, the thread must be able to withstand all of these processes and hold the seams together for the life of the garment. When we talk about sewing denim, there are four key issues that need to be considered:

1) What is the weight of the denim?

2) How much length of topstitching thread is required?

3) What finishing procedures will the jeans be subjected to?

4) What quality issues need to be addressed?

With these questions answered, the factories will be able to produce jeans that meet the requirements for today’s variety in denimwear. From a basic 5-pocket jeans to the most creative pair of high-fashion jeans, the sewing plant can produce the desired quality for each.

The thread of choice used by most quality denim garment manufacturers for topstitching and stress seams include:

| Brands | Substrate | Specific End Use |

| D- CORE | POLY COTTON CORESPUN SEWING THREAD | Denims/Jeanswear |

| D- CORE INDIGO | POLY COTTON CORESPUN SEWING THREAD – Dyed with Indigo Class Dyes |

Suitable for washdown effect Denims/Jeanswear |

| PERMA CORE / A-SERIES | POLY POLY CORESPUN SEWING THREAD | Denims/Jeanswear |

| PERMA CORE SUPER BLEACH |

POLY POLY CORESPUN SEWING THREAD – Special dyes used to ensure the colour remains intact even after bleach wash |

Suitable for Denims/Jeanswear meant for bleach wash |

| CHROMA | 100% MERCERISED COTTON SEWING THREAD | Denims/Jeanswear -Overdyeing |

| CHROMA SPC | SPECIALLY PROCESSED 100% LONG STAPLE COTTON SEWING THREAD | Denims/Jeanswear- Overdyeing + Laser Treatment |

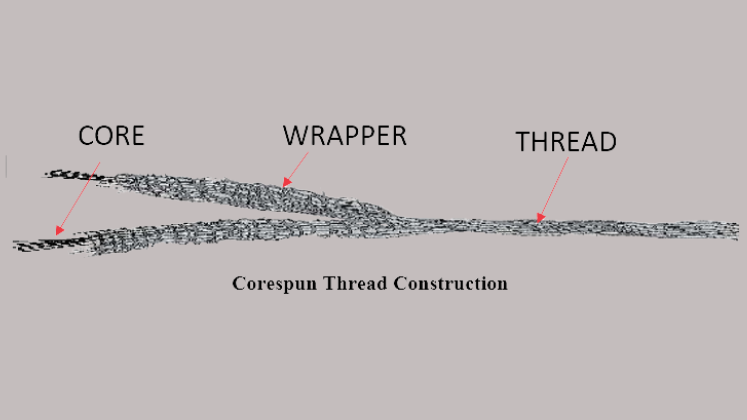

CORESPUN THREADS

Core threads are made by spinning a wrap of cotton or polyester staple around a bundle of continuous filament polyester fibres to form a yarn and then two or more of these yarns are twisted together to form a corespun thread. Generally, the core makes up approximately 60 per cent of the thread construction contributing to a more uniform and higher tenacity sewing thread as compared to a 100 per cent spun polyester sewing thread. For example, a T-60 PW Core thread will have a breaking strength of approximately 8.7 lbs, while a T-60 Spun Polyester thread will have a breaking strength of a little over 5 lbs.

When wrapped with a cotton wrapper, corespun threads have very good needle heat resistance. When wrapped with a polyester wrapper, corespun threads have excellent chemical resistance and colour fastness. The fibrous surface on either thread reduces the shiny look and also contributes to superior frictional characteristics as the thread passes through the sewing machine.

Some designers prefer the thread to wash down during the wash processes and if this is the case, you should select a Cotton-Wrapped Core thread (D-Core). Degrees of colour fastness will vary with particular shades. With this known factor, a user of Cotton-Wrapped Core should look at all wash codes to ensure the thread colour will be appropriately maintained. A&E and Gütermann also recommends doing pre-production wash testing to assure that the wash-down look will be acceptable.

On the other hand, many jean designers want the thread to maintain its colour for the life of the garment and offer a signature look. If colour fastness is key, then select a Polyester Wrapped Core thread (Perma Core). Also, with Polyester Wrapped products, one has the option of picking up the desired colour from a colour palette to obtain the look they want after the wash procedures. This will allow greater shade control, which will be maintained after continual washes by the consumer. A&E and Gütermann still recommends doing pre-production wash testing prior to going into production.

Cotton-Wrapped and Polyester Wrapped Core threads offer excellent abrasion resistance to the varied wash codes that the denim garments may be exposed to.

THREAD SIZE

Both of these thread types are available in sizes to meet the variety of denim fabric weights. From a Tex 40 to a Tex 120, one can achieve the desired performance throughout the sewing floor and after the varied finishing processes.

Utilise the correct size to obtain the desired look while maintaining seam integrity. Some basic sizes utilised in today’s denim are:

| Needle thread | Looper thread | Serging | Application |

| Tex 150 – T-300 | Tex 80 or Tex 60 | T-40 or T-60 | Extra Bold appearance |

| Tex 120 to T135 | Tex 80 or Tex 60 | T-40 or T-60 | Bold appearance |

| Tex 80 or Tex 105 | Tex 60 or Tex 40 | T-40 or T-60 | Normal |

| Tex 60 | Tex 60 or Tex 40 | T-40 | |

| Tex 40 | Tex 40 * | T-40 |

*8 oz denim usage or Chino twills

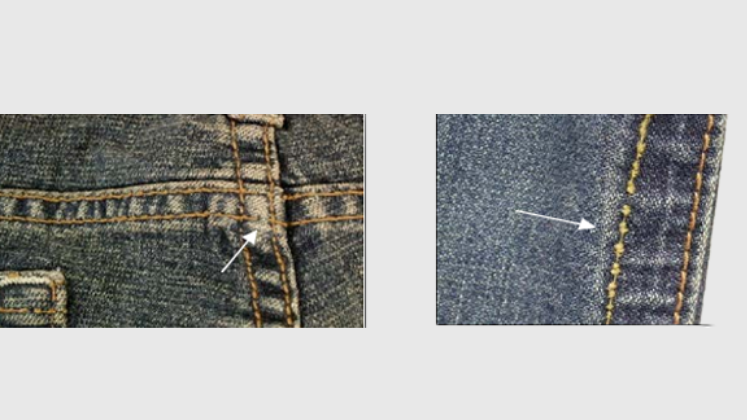

Cut or Broken Stitches

Most manufacturers of denim and twill garments that pre-wash garments after they are assembled have experienced problems with excessive ‘cut’ or ‘broken’ stitches. In fact, many manufacturers have found this problem to be significant reaching in excess of 30 per cent to 40 per cent of the products being sewn.

Many times, this problem occurs when a previously sewn stitch-line is crossed during a subsequent sewing operation and the needle damages the thread in the seam. Broken stitches can also occur when there is excessive abrasion or chemical degradation of the thread during the wash process. Let’s now discuss what are some of the major causes and solutions to these problems.

SOLUTIONS

– Many manufacturers have significantly reduced the number of ‘cut’ and ‘broken’ stitches by using high-performance sewing threads on stress seams. Make sure the correct thread type and size are being used in both the needle and bottom (looper) positions. Core threads that have a continuous filament polyester core are much more resistant to cutting and degradation than 100 per cent spun polyester thread constructions.

– Usually the larger the thread size, the more resistant the thread is to being cut by the needle or failure due to chemical degradation or heat. Because of this, many manufacturers have increased the thread size on critical operations including waist banding, seat seaming, etc. Typical thread sizes used on heavy denim run from T-105 down to T-60 depending on the desired look. Typical thread sizes used on twills used in the manufacturing of chino pants run from T-40 to T-60.

– Inspect the needle point at regular intervals and check for sharp or burred points. If the needle point is damaged, replace the needle. Many companies have found that it is best just to replace the needle on critical operations once or twice a day.

– Check for signs of needle heat or excessive heat exposure during laundering that may be melting the thread. Usually if the thread has been damaged by heat, the thread will have a hard melted surface that can be felt or seen using a magnifying glass. If you suspect that needle heat is a problem, try using a special coated needle or needle coolers to reduce needle heat. Make sure the thread has the proper type and amount of lube. Most major thread suppliers have developed high-performance lubricants to minimise heat damage on polyester threads. A cotton-wrapped core thread may be more resistant than a 100 per cent polyester thread.

– Use proper thread tensions. Make sure the stitch on the seam line is loose and able to move if it is hit by the needle. Tight machine thread tensions will NOT allow proper flexibility in the stitch and will increase ‘cut-stitch’ damage. Generally on chainstitch seams, the ideal stitch balance is when the needle loop on the underside of the seam lays over half way to the next needle penetration. This can be checked by unraveling the looper thread and observing the needle thread on the underside of the seam or checking the ratio of needle to looper thread. It is normally recommended that this ratio be approximately 60 per cent needle thread to 40 per cent looper thread consumed.

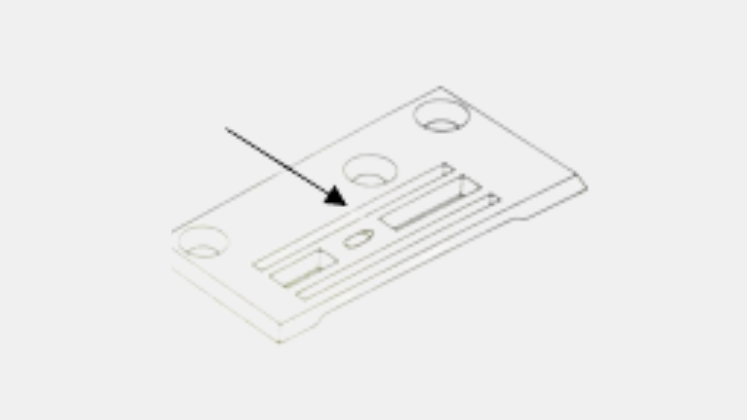

– Check the edges of the needle plate and presser foot needle holes to make sure they do not have any sharp edges or burrs that can damage the thread during sewing. Properly remove all burred or sharp surfaces making sure not to oversize the needle holes which can lead to excessive ‘flagging’.

– Inspect the feed dog teeth directly behind the needle holes and make sure they are not sharp. If required, buff the feed dog teeth with a wire wheel or with a stone if they appear to be sharp. Be careful not to remove too much of the feed dog teeth that could hinder the feeding or interfere with chaining.

– Use the minimum amount of presser foot pressure to get a uniform stitch length. Excessive presser foot pressure can cause the thread to be damaged when it is compressed against a relatively sharp surface. On some machines, it is sometimes necessary to use a presser spring with fewer coils per inch to give more consistent pressure even when crossing heavy seams.

– The proper type and capacity folder should be used to prevent stalling when crossing heavy seams. Feed stalling will increase the chances of ‘cut’ stitches.

DAMAGE DURING PRE-WASHING

Sometimes partially damaged thread from the sewing operation will fail during stone washing or other processes. Most of the time this damage is difficult to detect but should be investigated using the suggestions mentioned on the previous pages. On the other hand, many seams are damaged during the wash processes due to excessive abrasion, chemical degradation and heat degradation.

To reduce damage to the thread in the seams, A&E and Gütermann suggests the following:

- Make sure the correct thread type, construction and size are being used. For example, use Perma Core®.

- Work with your laundry to develop standards with regard to the type and amount of chemicals, rocks, cycle times and temperatures that are being used in both the washing and drying processes. You should monitor and properly test the following:

– Any changes of rocks and chemicals from one vendor to another

– Changes of cycle times

– Changes in temperature during the washing or drying cycles

- Evaluate the best way the garment should be processed – whether it should be inside-out or right-side-out, fly buttoned or not buttoned, etc. Care should be taken if the garments are turned right-side-out when they are still wet. Extra moisture in the garments can cause excessive whipping of the bottom hem seam causing excessive damage.

Denim – How to Sew X-Heavy Thread Sizes

Retail designers are always looking for a way to make their products unique and this definitely applies to sewing denim garments. From a thread perspective, this can include:

- Using contrast colour threads

– For all topstitching operations

– For different operations

– For different needles of the same operation - Using threads that will maintain their colour regardless of the wash process

- Using a 100 per cent polyester thread dyed with disperse dyes

- Using threads that will wash down depending on the severity of the finishing process.

- Using a cotton-wrapped core thread

- Using a true indigo dyed cotton wrapped core thread

- Using a thread that looks different than regular stitching thread.

– Two-colour thread like Design-A-Core

- Using different thread sizes that give a bolder stitch appearance.

LARGER THREAD SIZES THAT GIVE A BOLDER TOPSTITCH APPEARANCE

Tex Size = Gram Weight per 1000 metres of undyed yarn (see the World Wide Size Comparison Chart for yarn size conversion) Years ago, the most common size of thread used for topstitching denim was a Tex 60 or 80 or possibly Tex 105 size threads.

Recently many manufacturers have graduated to a Tex 120 size thread to give a slightly bolder stitch appearance. Today, many denim designers are looking at much heavier thread sizes including Tex 150, Tex 180, Tex 240 and even Tex 300.

This has created problems for many denim garment manufacturers because their normal denim sewing machines were not designed for these heavier threads.

WHAT DETERMINES THE THREAD SIZE THAT CAN BE SEWN ON A SEWING MACHINE?

On 301 lockstitch machines, the maximum needle thread size that can be sewn is usually determined by the capacity of the hook or shuttle in the machine, and the size of the needle being used. There must be enough clearance between the bobbin case holder and the hook base to allow the thread to move freely around the hook during the stitch formation. Sometimes an older hook will work better on larger threads because it has more play in the raceway allowing for more clearance for the thread.

Regular Single Needle Lockstitch Machine

The hook must also accommodate the use of larger than normal needles. In some cases, the retainer or gib of the hook is shaped differently to allow the thread to pull out of the hook with less resistance. Note that the hook must be properly lubricated.

Many sewing machine companies do make higher-capacity hooks that will allow larger threads to be sewn, but these are generally very expensive.

There are also machines designed for sewing very heavy threads used for sewing upholstered furniture and leather goods. Some manufacturers are purchasing these types of machines so that they can sew extra-large thread sizes up to Tex 500 or Tex 600 thread sizes.

Heavy Duty Single Needle Lockstitch Machine

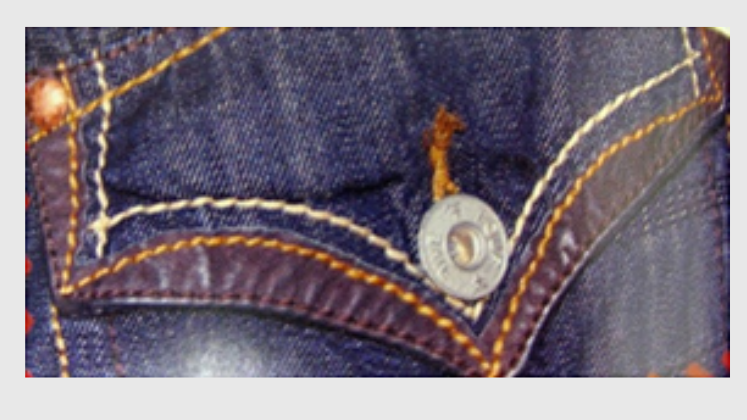

Another option for sewing heavy threads on 301 lockstitch machines is to sew the heavy thread in the bobbin and use a regular size thread in the needle. This means that the seam is inverted when it is sewn. This is a common practice when setting front pockets or outlining the fly on a 5-pocket jeans.

It is easier to use heavier thread sizes in the needle position of chainstitch machines, however, even these machines sometimes must be modified to allow the thread to be pulled up from under the needle plate with the least amount of resistance. This may include increasing the size of the needle hole in the needle plate.

RECOMMENDED NEEDLE SIZES FOR HEAVY THREADS

Most manufacturers who are sewing heavy denim are using size 140 needle. When sewing heavier thread sizes, larger needle sizes must be used. Note: Many times, using a larger needle size will increase the occurrence of fabric damage and broken stitches due to needle-cutting.

| Thread Tex Size | Minimum Needle Size (metric) |

| T-105 – T-135 | 140 |

| T-150 | 150 |

| T-180 | 160 |

| T-240 | 200 |

A simple test to determine if the needle and thread are compatible is to thread the needle with about 12 inches of thread. Hold the thread fairly at a 45-degree angle, and with a circular motion make the needle twirl around the thread. As the twirling motion of the needle slows down, the needle should slide freely from the top to the bottom of the suspended thread. If the needle does not slide easily, then sewing problems will probably result.

THREAD TENSIONS REQUIRED FOR HEAVY THREAD SIZES

Generally, a heavier thread size will require more thread tension to properly set the stitch on denim fabric. The heavier the sewing thread being used, the more needle thread machine tension that will be required. Lockstitch machines will also require heavier take- up spring pressure.

Also, all of the thread guides and eyelets may need to be used to help control the thread during the sewing cycle. This will also help to keep ‘French’ knots from forming in the thread path that can restrict the proper flow of thread to the needle.

Reach or Contact A&E and Gütermann for any kind of query and Technical Assistance at: Email: amefird@vardhmanthreads.in | sumesh.minhas@vardhmanthreads.in uday.bammanwadi@guetermann.com