In textile industry, one of the most interesting fields is its application in medicines. The focus of the R&D departments of the industry and their research institutes lies on developing veins, implants, scaffolds and reconstructing the body parts with textile technologies. Claudia Ollenhauer-Ries, our special correspondent from Germany reports.

Far beyond common bandages, plasters or compressive stockings exists a high-end application for textiles, which is growing at an amazing pace. Medics apply these to severely burnt victims, to reconstruct ears or as textile arm and leg sleeves for preventing skin tears in the elderly and bed-ridden. Biomedical textiles will be used as diagnostic tools, sensors for chemical or physical changes or enabling materials.

Dr. Martin King, Professor of biotextiles and textile technology in North Carolina State University’s College of Textiles said: “We are only just beginning to understand how these types of textile scaffolds can support cell growth, and we are just scratching the surface on how textiles may be used in many different internal and external medical applications.”

Medical textiles could be defined as “products and constructions for medical applications,” i.e. protective and healthcare textiles, dressings, bandages, pressure garments and prosthetics, hygiene products and antiseptic wound dressings.

Biomedical textiles could be defined as “fibrous structures designed for use in specific biological environments, where their performance depends on biocompatibility with cells and biological tissue or fluids”. (both definitions from CSIRO/Australia). Examples would be implantable materials and devices, biocompatible materials for regenerative medicine, such as tissue engineering as well as neural repairs.

Leaders in R&D

A few institutes have a worldwide reputation as partner for medics, industry and suffering persons: The Bolton Institute, Bolton/UK, with Prof. Subhash Anand heading the department for technical textiles, CSIRO, Belmont/Australia or Empa, Duebendorf/Switzerland as well as the Competence Network Biomaterials in Southern Germany, the ITA, Aachen/Germany, or the North Carolina University’s College of Textiles. Typical for all these institutes is the multi-disciplinary partnerships with scientists, research institutions and commercial companies.

The work of Prof. Subhash Anand focusses on engineering applications where performance and durability are of prime importance. The group works closely with industry and academia helping to design, produce, fabricate and test new materials and textile structures through applied research and collaborative engagement that have lead to products developed for markets such as health, medical, sports, lifestyle, special forces (army, navy and airforce) and other niche applications (firefighters, divers, motor drivers, etc.). In the area of medical and healthcare devices, the team develops biomaterials and speciality materials with healthcare related functionalities. Current areas of interest include: production and processing of novel biomaterials and development of multifunctional wound dressings.

CSIRO specialises in fibres and fibrous structures and has an established reputation in fine apparel wool research. The team also searches for alternative uses for wool as a component in technical textiles for medical, automotive, communication, aerospace or military applications. They say: “We are currently building on our expertise in protein biofibres such as wool, to create new or regenerated bio-derived fibres from natural or recombinant sources such as insect silks and feathers.” CSIRO is using its extensive expertise in textile design, manufacture and testing to develop wool-based textiles for two kinds of novel medical applications: Injury prevention limb covers to avoid or reduce skin tears and other skin injuries in the elderly as well as advanced wound management products with integrated sensor and response technologies, to promote improved healing of burns, scars, ulcers, and other skin injuries.

Swiss Empa combine their know-how and experience from, for example, the textile and materials science fields, and from biology and nanotechnology. The resulting developments include biodegradable materials for surgical implants, medical textiles and gerontological aids. Also at the focus of the research are functional textile systems which not only support the temperature regulation of the human body but also increase the comfort level when worn.

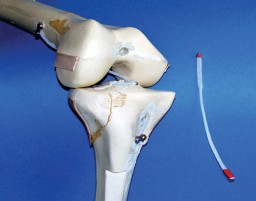

The Competence Network Biomaterials is a joint venture of the Competence Centres for Biomaterials and Organ Replacement Stuttgart-Tübingen and the ValleyTEC in Freiburg, all in Germany. The project was started in 2003. Until recently, the main focus of biomaterials research has been the development and testing of biomaterials and their surfaces. That focus of the Competence Network Biomaterials is now shifting towards the field of tissue engineering and in particular on the replacement of connective and supporting tissue. Orthopaedics and traumatology require large amounts of materials or tissue for the replacement of bones and joints. Bone defects must often be treated with autologous bone grafts, which are not available in sufficient quantities and must be taken from the patient in additional surgery. Cartilage defects can also be treated with autologous cartilage. The traumatic injury of ligaments, such as the frequently observed rupture of the anterior cruciate ligament (ACL), can be corrected with ligaments and tendons that are removed from a different part of the body of the patient. These kinds of operations are an extra strain on the patient and weaken the healthy structures at the site where material was removed.

The Institute of Textiles in Aachen (ITA) works closely with the German Wool Institute (DWI) at the Technical University RWTH Aachen and develops new materials for medical technologies. The ITA has spinning machines for pilot and industrial production for mono and multifilament polymeric yarns. The team of Mr Thorsten Deichmann produces implants and explants in small and large quantities: veins, stents, kerato prothetics, bands and wound tissues. If needed, they also design and produce prototypes of new machines and devices for textile production.

At the North Carolina University’s College of Textiles Martin King’s primary research thrust is currently in the area of biotextiles, biomaterials science and implantable devices. This is an emerging specialised field that has its roots in materials science, but which now relies heavily on the interaction between many different disciplines. Martin King’s particular approach has grown out of his interest in the degradation processes of fibres, polymers and textiles, and issues related to structure/property relationships. His work involves a number of arenas of activity, among those: The analysis of retrieved clinical explants with the object of understanding their failure mechanism and reasons for impaired performance in vivo or computer modelling of the function of implantable devices within a particular anatomical site, for example an arterial bifurcation, with a view to optimising their dimensional, mechanical and flow characteristics.

Enabling Materials

Enabling materials include new types of synthetic and natural polymers, adhesives and tissues. Many of these materials are in fibre form and require precise manufacturing techniques to ensure uniformity, purity and reliability. Often, the fibres are made from polyester, polypropylene or polyethylene for implants – the ITA works in this area as well. For outer uses, wool, cotton or silk from insects would be used – the CSIRO is a leading institute in this matter.

At the Empa, new biopolymers will be biotechnologically produced and chemically modified, if needed, to achieve the desired functionality. To date they claim to have “a leading position in tailored biosynthesis of polyhydroxyalkanoate (PHA) and its purification”. An increased emphasis will be placed on the study of the interface between novel materials and biology; examples include tissue engineering, biomineralization and biofilm inhibition. Dr. Arie Bruining, heading the project team, says: “In the coming years we aim to produce prototypes, which can be further developed into marketable products by industrial partners.” New coatings will improve the properties of the implants and minimize wear and tear. Dr. Bruining reports: “We possess state-of-the-art capabilities in amorphous hydrocarbon coatings, and our goal is to develop new multi-purpose versions. New TiO2 and Nb2O5 coatings with defined micro- and nanotopographies will be developed and chemically functionalized via electrochemical precipitation and anodizing. Coating them with biomolecules will drastically reduce implant abrasion.” The interaction between material surfaces and the contacting cells is complex, and the effects on both materials and cells are manifold. The Empa team develops tools to observe cultured cells on-line, i.e. in real time, during the entire culturing period, thus gathering exact information about, among others, the functionality and state of differentiation of the entire culture as well as of individual cells. Dr. Bruining’s view into the future: “Based on our knowledge of the cell-material-interaction and our expertise with respect to the development of active implants, it will be possible to define and develop a series of unique implants, such as artificial muscles, neuroimplants, biotoxicology sensors, and reduced-abrasion and bioactive surfaces.”

Application Examples

An example is the Intelligent Knee Sleeve, developed in a partnership between CSIRO and the University of Wollongong’s Intelligent Polymer Research Institute and Biomechanics Research Laboratory. The sleeve is a biofeedback device that monitors the wearer’s knee joint motion. It resembles a conventional fabric knee guard but has a disposable electronic fabric strain sensor and a signal processing system mounted on it. As the knee bends, the electrical resistance of the fabric sensor changes, and when the knee joint reaches the correct angle for safe landing, the signal processor beeps. When used in training the beep provides athletes with real-time feedback about lower limb orientation during jumping and landing and reinforces the correct landing technique. The sleeve is being trialled by the Australian Football League to help players avoid knee injuries such as rupturing of the anterior cruciate ligament.

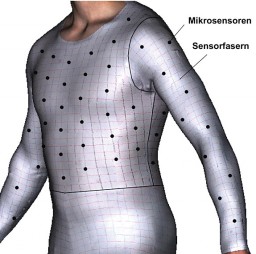

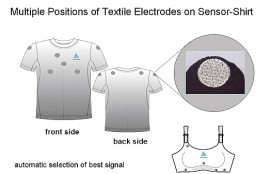

Empa developed in partnership with Odlo International/Huenenberg/Switzerland, Bischoff Textil, St. Gallen/Switzerland and other partners a t-shirt with embroidered electrodes. These electrodes would register the signals of electro cardigrams without cables. Another application of this technology is monitoring athletes or elderly persons over a longer lap of time. Right now, the device will be commercialised with one more producing partner as a breast belt. A step further is the commercialisation of a monitoring t-shirt Vital Jacket by Biodevices, S.A., a spin-off from IEETA (Institute of Electronics and Telematics Engineering of Aveiro/ University of Aveiro/Portugal). Vital Jacket heart monitoring shirt is a “wearable vital signs monitoring system that joins textiles with microelectronics.” The shirt was designed to be used in a variety of settings, from hospital rooms to the home, and for people on the move. The Vital Jacket provides continuous or frequent high quality vital signs monitoring. It comes in two versions: HWM100 that stores data on a SD memory card for posterior analysis in a PC and, HWM200 that allows on-line visualization using a smartphone/PDA. The device was designed for use in a “smart house for the elderly” that could monitor the occupants.

Ellis Developments Ltd., Newark/U.K., develops and produces textile implants like customised shoulder rotator cuff repair devices known as “The Nottingham Hood”. This was screwed to the metallic implant to reattach the Deltoid muscles to the middle of the humerus, and a standard Nottingham Hood was used to reattach the rotator cuff at the shoulder.

Ellis is also involved in a project called “Spider-like Silks for Surgical Implants”. It is addressing the clinical need to develop sophisticated resorbable sutures to improve current surgical procedure and patient satisfaction particularly in the field of internal suturing. The project builds on ongoing collaborative work between Oxford Biomaterials Limited, Oxford University, Pearsalls Limited and Ellis Developments Limited. They are developing a suture thread from Oxford Biomaterials’s fibre Spidrex, which has mechanical properties similar to spider’s silk. Further, it provides an excellent substrate for mammalian cell adhesion, while sequence characteristics make it chemically malleable and initial trials show that it is biocompatible and can be rendered pyrogen-free. Julian Ellis: “We have evidence that like spider silk and unlike conventional medical silk, it will be resorbable over a period of months.” Spidrex fibres are being braided into a range of suture threads. The suture would provide surgeons with a mechanically reliable means of wound closure without the necessity of a follow up intervention for suture removal. The world market for a resorbable suture is estimated at $100 million, as concerns over prion disease from collagen-based sutures and adverse patient reactions from PLLA sutures have resulted in product withdrawal.

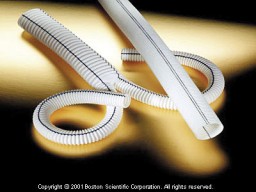

Hemashield Gold vascular grafts of Boston Scientific, Natick/USA are probably the most used, most studied and most trusted vascular grafts available in the market. The knitted double velour vascular graft is indicated for use in the replacement or repair of arteries affected with aneurysmal or occlusive disease. More than 2 million Hemashield grafts have been implanted worldwide demonstrating clinical efficacy and improved outcomes. Over 45 years experience, 8 million implanted textile grafts, and 2 million implanted Hemashield grafts show the clinical efficacy of Hemashield grafts. More rapid healing, excellent biocompatibility and outstanding patency combine to improve outcomes.

Producing Medical Textiles

Prof. Dr. Thomas Gries from the ITA, Aachen/Germany, shows how the whole textile chain is involved from chemistry to the final product: The yarns used could be PVDF (a highly non-reactive and pure thermoplastic fluoropolymer) monofilaments with diameter of 60 µm or multifilaments with 30 filaments with diameters of 17 µm each. Specific surfaces as well as blendings with additives could be done. Yet, the production is at a low stage on pilot plants. The yarns could be twisted, plied, air-jet textured or coated, gaining so the desired structure and strength. Flat and tubular could be produced on specially designed raschel warp knitting machines. Even branched tubular structures with various geometries could be produced. Braiding, especially the ITA-patented 3D braiding technology, will be used for alloplastic criciate ligaments with continuous geometry modification and adjustable elastic characteristics.

Of course, nonwovens are not to be missed: Resorbable materials with incorporated bioactive substances could have a great future. Narrow weaving machines at laboratory scale and industrial weaving machines could produce various structures and material combinations.

Finishing is of great importance, as bioactive and thermal active substances can be applied to whatever textile product.

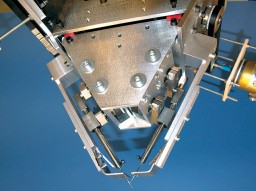

Sewing and embroidering technologies are used to combine various materials, tailoring textile structures, make reinforcements and well-directed accumulation of material. Due to the delicate and tiny textile structures, only computer directed devices can do this job. For instance, the ITA develops special devices for sewing medical textiles like the single sided sewing machine.

Julian Ellis of Ellis Developments focuses on embroidered fabrics: “The textile implants can be made to precisely fit the particular patient economically.” He described embroidery as providing “mass production in units of one”. This characteristic will also be important in a future medical application, he predicted, where embroidery’s ability to place fibres precisely in complicated structures will result in its use in scaffolds for tissue engineering.

Tissue engineering / regenerative medicine is an emerging multidisciplinary field involving biology, medicine, and engineering that is likely to revolutionize the ways we improve the health and quality of life for millions of people worldwide by restoring, maintaining, or enhancing tissue and organ function. In addition to having a therapeutic application, where the tissue is either grown in a patient or outside the patient and transplanted, tissue engineering can have diagnostic applications where the tissue is made in vitro and used for testing drug metabolism and uptake, toxicity, and pathogenicity. The foundation of tissue engineering/regenerative medicine for either therapeutic or diagnostic applications is the ability to exploit living cells in a variety of ways. Often, textile structures like felts made from PTFE or polyester are being used to give the engineered tissue strength, flexibility and shape. At an experimental stage, 3D embroideries have been used to reconstruct an outer ear.

But, as Competence Network Biomaterials experts say: The currently available biomaterials do not fully meet the functional and biological demands required by tissue engineering. Disadvantages lie in particular in the mechanical behaviour of the material and the limited ability to induce desired cell reactions. Thus, the replacement of bones, ligaments and cartilage through biomaterials colonised with cells (tissue engineering) is still in its infancy.

Conclusion

Medical and biomedic textiles are cutting-edge technology from all sectors of the textile chain. A lot of the products will be tailored individually, others will be produced in small quantities (compared to basic wovens, knits or nonwovens). Textile technologies can produce semi-finalized 3D products. A lot of development work is under way from fibre to finishing. Sewing and embroidering have both potential in this, but also need development. In any case, every production step will be monitored and the products will be thoroughly tested at any stage.