Football today is hand stitched, machine stitched or thermally bonded. The latter is a state-of-the-art patented process used exclusively for balls used in world class matches. Jabulani – the official football for FIFA World Cup 2010 is an example. However, most of the footballs present in the market are either machine stitched or hand stitched using 32 panels of waterproofed leather or plastic. Making a football, in its essence, is just like making a garment, using the same processes from pattern making, cutting to finishing and testing. Team StitchWorld visited some of the leading football manufacturers in the country with the intention of understanding the criticalities of football manufacturing and suggests a fully mechanized sewing setup for the same.

The three main components of a soccer ball are the cover layer, the lining (usually of 3-4 layers) and the bladder.The word “cover” refers to the outermost layer of the ball, which can be one of the many variations of synthetic leather, ranging from AI-2000, Japanese Teijin Cordley, Microfiber, English Porvair, Korean Ducksung, Leather Art Pakistan Synthetic Leather, and PVC (polyvinyl chloride). Best soccer balls used in competition and by professionals are produced by using AI-2000, Cordley, Ducksung, Mircofiber or other types of PU synthetic leather. Promotional soccer balls or practice balls are usually constructed with PVC or rubber (moulded or stitched) covers.

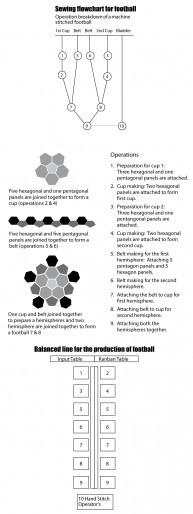

Operation breakdown with machine and manpower requirement

| S. No |

Operation Description | Machine Type | Machine From Typical | Machine From Golden Rich | Machines From Baoma | Process Cycle Time (Sec) | Production | Operators Required |

| 1 | Three Hexagon and one Pentagon are attached for cup 1 | Flat bed Machine | GC-0303CX | JS-20628-DY | GC-0378-1 | 27 | 1066.666667 | 1 |

| 2 | Two Hexagonal panels are assembled with above preparation to give the First Cup | Flat bed Machine | GC-0303CX | JS-20628-DY | GC-0378-1 | 39 | 738.4615385 | 1 |

| 3 | Three Hexagon and one Pentagon are attached for cup 2 | Flat bed Machine | GC-0303CX | JS-20628-DY | GC-0378-1 | 27 | 1066.666667 | 1 |

| 4 | Two Hexagonal panels are assembled with above preparation to give the Second Cup | Flat bed Machine | GC-0303CX | JS-20628-DY | GC-0378-1 | 39 | 738.4615385 | 1 |

| 5 | First Belt is made | Flat bed Machine | GC-0303CX | JS-20628-DY | GC-0378-1 | 69 | 417.3913043 | 2 |

| 6 | Second Belt is made | Flat bed Machine | GC-0303CX | JS-20628-DY | GC-0378-1 | 69 | 417.3913043 | 2 |

| 7 | Attach belt to cup (First Hemisphere) | Cylinder bed machine | TW3-341 | Js-2810-2820 | GC-2618-1 | 70 | 411.4285714 | 2 |

| 8 | Attach belt to cup (Second Hemisphere) | Cylinder bed machine | TW3-341 | Js-2810-2820 | GC-2618-1 | 70 | 411.4285714 | 2 |

| 9 | Attach both hemisphere leaving last five seams open | Cylinder bed machine | TW3-341 | Js-2810-2820 | GC-2618-1 | 55 | 523.6363636 | 2 |

| 10 | Attaching bladder and closing final three seams | Local | 470 | 61.27659574 | 13 | |||

| Total | 935 | 411.42 X 2 = 823 | 27 | |||||

| 15.58 mins. | ||||||||

Note: All calculations are made keeping the daily working time at 480 mins.

Bottleneck operation is at operations 7 and 8 and operator requirement is calculated at 823 pieces a day

Beneath the cover fabric, comes the lining layers contributing to the material thickness thereby playing a vital part in the quality of soccer balls. Professional soccer balls usually have four or more layers of lining. Promotional or practice balls are often constructed with less layers of lining. These layers of lining are composed of polyester and/or cotton bonded (laminated) together to give the ball strength, structure and bounce. Molten latex is used for bonding these layers together and with the cover fabric, thereby giving the final integrated shell fabric that shall be cut and hand stitched around the bladder to give the final ball.

A 32 panel casing is the most common option forming the most popular version “Buckminster ball” with 20 hexagonal and 12 pentagonal panels. Other traditional designs are 18 and 26-panel constructions, used in various professional leagues, including Scottish and English leagues until 2002.

The innermost and most crucial component is the spheroidal shaped bladder which holds the air. Bladders are usually made from latex or butyl. Compared to latex bladders, butyl bladders retain air for longer periods of time. Latex bladders tend to provide better surface tension. However, butyl bladders offer the excellent combination of contact quality and air retention. Most balls use butyl valves for air retention, with higher end balls using a silicone-treated valve for superior performance.

Factory based machine stitchers in China produce between 36 to 40 footballs per day; however, they are usually working a 10-hour shift for six days a week. In contrast to this full-time hand stitchers stitch between four to five balls a day, working six days a week for an 8-hour shift per day.

Factory based machine stitchers in China produce between 36 to 40 footballs per day; however, they are usually working a 10-hour shift for six days a week. In contrast to this full-time hand stitchers stitch between four to five balls a day, working six days a week for an 8-hour shift per day.

The process of manufacturing footballs is similar to that of garments involving comparable preparatory methods and sewing being done using assemble lines.

Preparatory steps for (32-panel) football manufacturing

The lamination of layers: 3 to 4 plies of polyester are bonded on the inside of outer covering layer (PU), one by one, using molten latex between them. Then they are left to dry. The same process can be done using a lamination machine, XJ16B-D2 (Zhangjiagang Jiuyi Machinery Co.).

Cutting the panels: 20 hexagonal and 12 pentagonal patterns are cut from the bonded lay using die cutters. A certain pentagonal panel is punched with a hole, as an opening to the valve of the bladder. Automated gantry cutting machine, XCL4 350/400 (Zhangjiagang Jiuyi Machinery Co.) can be used for cutting the panels.

Printing: Screen printing is done on the cut panels. Grafica Nano Print can be an ideal machine for the same.

“Jabulani”, the moulded football that was recently used in the FIFA World Cup 2010 belongs to the latest third generation of football manufacturing, using an innovative moulding process for manufacturing, where instead of stitching the panels together they are spherically moulded through the use of adhesives and heating devices.