The recent launch of stitchless shirt by Arrow is probably a tipping point in the history of fabric joining technology and would expand the use of welding and bonding technology among apparel and home textiles. The technology that’s already somewhat in use in undergarments and seamless garments, is primarily used in making tents, filters, signs, banners, geo material, awnings and inflatable products. StitchWorld is expanding scope of coverage beyond stitching to review the bonding, welding and seam sealing technology that are offered by different brands – their applications, advantages and limitations. In this first article, while introducing the basic concept of stitchless, the write-up also raises some unanswered, but pertinent questions on the concept, and which SW will endeavour to seek over the next one year so that users of the technology are better equipped to get the best from stitchless technology.

Conventional Sewing and Seam Sealing by Taping

The most common and conventional method of joining fabrics is by sewing with needles and threads and which requires access to both sides of fabric with exceptions like blind sewing and one-sided sewing thereby allowing immense flexibility in joining tubular or other 3D shapes. These seams are used in garments made of porous fabrics and worn as innerwear and outerwear over the decades. However, if the garment is made from non-porous materials such as those used for water proof, fire resistant or chemical resistant clothing, then the perforations caused by a conventional sewn seam will compromise the integrity and performance of the garment. Therefore, for such applications, the fabric plies are first joined by traditional needle and thread sewing and then the sewn seams are sealed with tapes.

Seam sealing tape has a thermoplastic (hot melt) adhesive coating on one face. The hot air at precisely controlled temperature is applied to the hot melt adhesive which is activated. In the activated form, the tape is applied on the reverse side of the seam using pressure. On cooling, a strong bond is formed between the tape and the seam which seals the needle holes and prevents wind or water from penetrating the seams. Sealing tape fabric can be woven or nonwoven depending on the requirement. Tapes can be made of a single, double or triple layer. Tapes are attached by pressure-sensitive adhesives which are either rubber or acrylic based, solvent based, heat activated or fire retardant.

Different Technologies for Fabric Joining

Seam Welding

Welding, as the name itself suggests, refers to thermal fusing of fabric plies and thus creating seams in knitted, woven, and nonwoven thermoplastic materials without adhesives, chemical binders, staples, needle, or thread. The three principles on which the welding works are heat, speed, and pressure. The precise combination of these three allows one to achieve a properly welded seam in thermoplastic materials while the overall quality of seam would also depend on high yarn density and thermoplastic content, tightness of weave and uniformity of material thickness. How do each of these factors affect seam welding and what is the right way to do welding in different cases is an interesting topic of discussion in following articles.

The random orientation of fibres in nonwoven fabric also gives it excellent bond strength, whereas, in wovens and knits, the style and elasticity of construction affect the bond strength of welding. (How each of these factors affect bond strength will be explored in subsequent articles; coated materials are often welded to seal the seams). The nature of coating, film thickness and other substrate properties are important parameters in such cases.

The random orientation of fibres in nonwoven fabric also gives it excellent bond strength, whereas, in wovens and knits, the style and elasticity of construction affect the bond strength of welding. (How each of these factors affect bond strength will be explored in subsequent articles; coated materials are often welded to seal the seams). The nature of coating, film thickness and other substrate properties are important parameters in such cases.

Materials suitable for processing with the welding technique include 100% synthetics such as nylon, polyester, polypropylene, polyethylene, modified acrylics, some vinyl, urethane, film, coated paper, and synthetic blends with 35-50% non-synthetic fibre content.

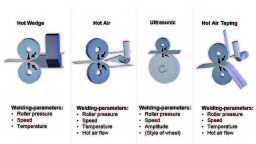

Out of several methods of welding technology, the most popular methods are hot air welding, hot wedge welding and ultrasonic welding. Laser welding and RF welding are not so commercially popular methods of welding.

Hot Air & Hot Wedge Welding

In hot air welding, a hot air nozzle delivers heat, while in hot wedge welding, a precisely controlled high temperature wedge (a triangular shape of metal object) is injected between two or more layers of thermoplastic material, thus heating the thermoplastic fabric and preparing the two surfaces for molecular bonding. Speed is the amount of time the heat is applied to the thermoplastic material and is controlled by the rate at which the material passes through the system. Pressure is used to compress the heated thermoplastic materials together during the sealing process to complete the molecular bond between two or more surfaces. Variable air pressure is applied to the weld rollers creating the necessary strength. Driven weld rollers advance the thermoplastic material through the system at a precisely controlled variable speed.

Usually each heat system can be used in place of the other. However, there are certain applications and scenarios when one heat system may be better than the other. While thin film and thin fabric of non-textured surface can be welded by hot wedge welding technique, the textured and thicker material should use hot air welding method. (Details of intricate use of welding and its advantages will form the content for further articles on the subject). Also hot wedge welding creates a comparatively quieter work environment. It is mostly used for long straight seams or 2D seams. The temperature range may vary from 400 degree C to 750 degree C depending on the types of material but there is no ready reckoner available for how much temperature is required for what material. (Through this new concept on bonding and welding, we will try to find answers for different welding parameters that are required for different materials).

[bleft]Stitchless fabric joining should not be confused with “seamless”. Seamless garments are made by engineered circular knitting technique where common requirement of 3D shapes & edge finishing can be done during knitting thereby eliminating the requirement of additional sewing. The seamless garments conceptually aim to eliminate seams, thus the nomenclature, but actually can have minimal seams. The stitchless seaming technologies can be used complementarily with seamless knitting. [/bleft]

Ultrasonic Welding

Welding with ultrasonic technology is probably the most diverse of the applications; under this technology ultrasonic energy is used to seal, slit, form and converts textiles into garments or other products. It can be used for many applications like disposable protective clothing, covers and cloths from the medical sector, filters, roller binds, lingerie and outdoor garments. Ultrasonic welding is often compared with radio frequency (RF) welding, which according to some are similar technologies while for others both are different. (This article will also try to find answers for the advantages and disadvantages for both, and most importantly specific applications for each technology).

An ultrasonic welding system contains a power supply which takes line power and changes it to high ultrasonic frequency, while a converter containing piezoelectric crystals mutates the incoming electrical signal into mechanical vibrations with the same frequency and when applied to fabric under pressure are absorbed and reflected at the interface. This vibration energy is delivered to the fabric or film with the help of a horn having a maximum width of about 25 cm which is large for many of the applications. The resulting molecular and interfacial friction produces heat which causes the material to soften and adjacent layers to fuse.

Advantages of this threadless sewing technique include speed, width of seam (up to 5 mm), versatility of material movement (left, right, mechanical or electronic), programming and cutting, sealing, decorative seam crimping and welding in one step.

[bleft]While the stitchless fabric joining technology has been common for awnings, ductings, filtrations, medical cushions, inflatables, tarpaulins, tents and signages, it is expected that it will invade apparel segment for functional benefits or pure aesthetics. The ultimate customer need will decide the future of stitchless fabric joining. [/bleft]

Ultrasonic welding can be continuous, i.e. either the fabric is passed through a set of rotating rollers or batch, i.e. fabric is stationary and, placed over a fixed anvil, and the horn descends on it and fuses the layers together in the seam design of the stationary anvil. This batch process of ultrasonic welding is also called impact welding or plunge welding.

Tapes and eye shields are attached to a surgical face mask and ties are attached to a nonwoven medical gown, all using the plunge welding technique. In plunge welding or impact welding, flat shaped anvil is weld by making vertical movement and therefore is especially useful for small area welding in batch process. Other example of plunge or impact welding include punching of buttonholes, joining bra straps, darts, buckles, collar stays, belt loops and zipper stops.

Continuous ultrasonic welding machines are similar to sewing machines and can have flat or feed off the arm machines equipped with a cylindrical bed, a rotary stitch anvil and an ultrasonic system above the wheel used for making tubular parts, such as sleeves, pant legs or continuous tubes. The fabric is fed through a folder beneath a stationary horn to give a lapped seam or a double felled seam.

Stitch patterns produced by an etched anvil of ultrasonic welding include solid lines, dots, single stitch, double stitch, zigzag, slant, rope, serpentine, and flower and leaf patterns. Ultrasonic welding produces smooth, durable, and clean edges with no discolouration of the fabric. There is no warm-up time before operation, and no scope of smoke or burned plastic leftover.

When equipped with a cutting edge, the anvil, a backup part for the support of work piece, cuts and seals the edges at the same time. Tapes and eye shields are attached to a surgical face mask and two sides of the disposable bags are joined together, which are examples of welding with simultaneous cutting of edge.

[bleft]“Stitch-free technology can either be in the form of welding or bonding, which though often quoted as same, are two different concepts. Fabric welding is the process of joining pieces of only synthetic fabrics using heat and pressure, either directly or by application of a tape. Bonding, on the other hand, can be performed on any fabric by placing a heat activated adhesive material between them.”[/bleft]

Seam Bonding

While welding is based on thermal joining, the bonding technology works on chemical or liquid glue bonding. It uses an adhesive between two layers of materials and bonding occurs through the effect of heat, pressure and moisture. Depending on the type of textile to be bonded, different types of adhesives such as hot melt adhesives or spray glues are used. This technology is also used to seal the insertion holes made by the traditional needle sewing. (Why the applications of bonding are mainly in medical use garments, protective clothing and sportswear is a topic for discussion in forthcoming issues).

The adhesive used in bonding are mainly heat melted adhesives, known as TPA (Thermo Plastic Adhesives). Depending on the fabric type and fibre characteristic, different types of TPA’s are used for the bonding purpose. For example, to bond nylon fabrics Modified Polyamides are used, which has the same monomer units like the Nylon. In the same way modified polyester adhesives are used for the polyester fabrics. These melted adhesives are flooded through the yarns of the fabric and solidifies on cooling to crystallize and make a web among the fibre of the yarns. As bonding uses external adhesive between two layers of fabric, this can be applied to non-thermoplastic fabrics and especially 100% cotton.

The liquid glue technology is a single step process – the hot melt react type liquid glue is dispensed from a cartridge fitted in machine at measured flow between two layers of fabric to be joined once the glue reacts with moisture in the air (also called “cured”) it will not melt again. For the reaction it doesn’t need any additional temperature, just room temperature is fine.

The adhesive tape bonding technology uses a three step process – in the first step, adhesive tape is applied at the edge of the fabric with backing paper on top, the tape is applied with a sewing machine like machine wherein single layer of fabric is passed through two rollers and tape is attached from a tape dispenser. In the second step, the backing paper is peeled off which is generally done manually by hand just before the third step. In the third step, the second ply of fabric is placed on the adhesive tape and regulated temperature and pressure is applied to attach the second ply. The machine used for the third step may be of three types: first, a simple continuous fusing machine can be used where the seam lines are straight and flat; second, flat bed fusing machine with 3D shaped bucks can be used where seam lines are curved; and lastly, sewing machine like bonding machines with continuously heated top and bottom belts are used for single or tubular assembling (like sleeve). The adhesive tape is normal hot melt glue and cannot be re-heated because it will melt again.

Technology Suppliers

Currently the adhesive tape technology is common and at nascent stage of commercialization (The Arrow stitchless shirt and lingerie). Although liquid glue technology holds promise with likely advantages over adhesive tape technology which the article series is going to explore, it is yet to find commercial acceptance. There are traditional sewing machine brands getting into seam sealing, welding and bonding machines segment and simultaneously there are brands specializing in seam sealing, welding and bonding machines only. Among the conventional sewing machine brands, currently PFAFF, Brother, Schips and Vetron are the only brands which offer traditional sewing as well as stitchless fabric joining machines. The other brand from garment technology domain is Macpi, which is present in garment finishing and spreading and cutting machines, and also offers the complete range of adhesive tape bonding technology.

The stitchless fabric joining has given birth to some spring-off specialized companies during the last decade who offer just this non-conventional way of fabric joining. As the two technologies are converging to a common product domain, i.e. apparel, an interesting competition is emerging with more of more stitchless fabric joining technology being displayed in several garment machinery exhibitions.