In a scene from Minority Report Tom Cruise strides through a futuristic mall, his every move tracked by 3D screens scanning his eyes. In an instant, the screens spring to life, calling out his name with ads personalised just for him.

What was once science fiction is inching ever so closer to becoming a reality, particularly in the fashion industry. We spoke with experts from fashion brands, retailers, manufacturers and tech companies to see how AI is transforming the industry.

AI is playing a critical role in improving demand forecasting, inventory management, product search and photoshoots. Almost all major brands are leveraging AI to predict demand, reducing overstocking or understocking. AI tools are also used to provide personalised sizing recommendations, reducing returns and improving fit, apart from streamlining product development, drastically reducing sampling times and enhancing collaboration across design teams.

Whereas, e-commerce platforms like Myntra and Ajio use AI for better product discoverability and efficient product tagging.

In manufacturing, AI tools can instantly generate technical design files from sketches, detect potential flaws and simulate how fabrics will behave, ensuring designs are production-ready with fewer errors and less waste. Triburg’s integration of AI allows for rapid virtual sampling and precise CAD files, helping brands make quick decisions and deliver products faster.

Moreover, AI’s role extends to predictive maintenance in manufacturing, with companies like Lectra and Smartex using AI-powered sensors to anticipate machine breakdowns and optimise factory operations. Read on to discover more about AI’s impact on fashion.

Demand Forecasting For Better Agility

Probably the most used application of AI in fashion today! One of the main obstacles in the fashion industry is to manage inventory. By improving collection planning, AI helps brands avoid the costly problems of understocking or overstocking. In fact, nearly all major global and local brands are tapping into AI to predict demand and stay ahead of the game. For instance, global brands like Zara, H&M and SHEIN are at the forefront of the AI-driven inventory forecasting revolution. Zara uses AI to analyse customer behaviour and sales trends, enabling it to restock popular items quickly and avoid overproduction.

Similarly, H&M employs AI-driven analytics to refine its inventory strategies, ensuring that products align with market demands while production happens in required quantities only. AI is also playing a crucial role for sportswear giants like Nike and Adidas, which use predictive analytics to anticipate demand across various markets. Similarly, Uniqlo combines customer insights with weather and trend data to optimise inventory, ensuring it meets customer needs effectively.

A standout example of AI’s use in predicting demand is the fast-fashion giant SHEIN. The brand’s AIdriven inventory system is designed to predict trends with incredible precision. SHEIN analyses vast amounts of data from customer behaviour, search patterns and purchase history to anticipate what customers will want next, ensuring that trending products are produced and stocked in the right quantities.

SHEIN also integrates AI into its supply chain processes to track inventory levels in real time. Additionally, AI helps SHEIN monitor regional demands, enabling localised inventory planning for better customer satisfaction. In India, fashion retailers like Myntra and Reliance Trends are utilising AI to analyse consumer behaviour and predict demand trends.

Myntra, a leading fashion e-commerce platform, ensures that trending products are readily available, while Reliance Trends employs AI to maintain efficient stock levels across its vast network of retail outlets. ABFRL, which owns brands like Louis Philippe, Van Heusen and Pantaloons, utilises AI and machine learning to analyse historical sales, seasonal trends and regional preferences.

Its AI systems optimise supply chain management by predicting which products are likely to sell in specific stores or regions. This minimises stockouts and overstocking, improving profitability. Arvind Ltd., a leading Indian conglomerate having textiles, garments and brands in its portfolio, uses AI to streamline its production planning and inventory distribution. By forecasting fabric and garment demand, Arvind optimises manufacturing schedules for more streamlined processes. Westside, a fashion retailer under Trent Limited, also uses predictive analytics to align inventory with customer demand.

The retailer analyses sales data across stores, local preferences and emerging fashion trends to keep its product mix fresh. This helps improve in-store and online inventory turnover. “Another use of AI-based demand forecasting in retail is buying and merchandising planning. AI has simply transformed retail buying and merchandising planning by enabling a store-specific approach rather than relying on traditional clustering methods. For example, if a fashion brand has 50 stores across India, using AI tools allows the brand to treat each store as a unique retail sales point, analysing individual variables for better inventory management and range building,” said Vinit Doshi, Head-Product, Sourcing and Design, Celio.

| JIT AI-driven forecasts help factories implement JIT (JustIn-Time) production. Knowing demand in advance allows better planning of machine utilisation, reducing idle time and energy consumption. For example, if a factory is using AI-based tool that can predict demand for specific styles, colours or sizes, it enables the factory to prioritise production lines accordingly. |

The French men’s apparel brand has 65 stores across 25 cities and is targeting to add 100 stores in the next two to three years. Celio has adopted AI through its partnership with Increff, a retail SaaS company, to improve its retail operations. Instead of grouping stores into clusters, the brand now treats each store as a unique entity. This data-driven approach allows Celio to address the specific needs of each location by analysing factors like past sales and local consumer trends, which help optimise inventory management.

One of the most impressive outcomes of Celio’s AI adoption is the increase in full-price sell-through from 48 per cent to 60 per cent. It aims to achieve over 90 per cent forecasting accuracy.

However, “AI relies on past data, which may not always reflect sudden trend changes, like a new seasonal colour. This highlights the need to combine AI insights with human judgment to make quick adjustments when the market shifts unexpectedly,” cautioned Vinit Doshi.

“Today’s consumers are much more informed. They research products online before stepping into a store. This shift means that brands like ours need to move away from generic offerings and instead analyse customer behaviour and preferences to provide targeted, personalised experiences. AI allows us to track such behaviour, identify specific needs and deliver recommendations that align with what customers are looking for,” stated Ranjan Sharma, CIO and Head of Supply Chain, Bestseller India. The brand currently has 362 exclusive brand outlets and markets and sells six Bestseller brands – Jack & Jones, Vero Moda, Only, Selected Homme, Jack & Jones Junior and Vero Moda Girl.

London-based Delvify.ai introduced an AI-powered Material Management Platform that transforms how fashion brands and vendors discover materials, speeding up production.

“The Generative AI algorithms predict trends using a variety of statistical models. In layman’s terms, they look at all the past historical trends and ‘guess’ what is next. If you see many more blue T-shirts being purchased, then it is likely that blue T-shirts will be demanded.

The newest generation of models can go much deeper now and you can guess the colours, patterns or even styles that define a trend,” said Charles Allard Jr., Founder, Delvify.ai.

AI-driven forecasts also help factories implement JIT ( Just-In-Time) production. Knowing demand in advance allows better planning of machine utilisation, reducing idle time and energy consumption. For example, if a factory is using AI- based tool that can predict demand for specific styles, colours or sizes, it enables the factory to prioritise production lines accordingly and hence it can quickly adjust production for trending products, improving speed-to-market.

“AI has revolutionised our JIT production,” said Nitin Kapoor, CEO and Co-founder, IBA Craft, a cross- border e-commerce company specialising in apparel and furnishings. “Before AI, production was reactive, leading to delays and higher inventory costs. Now, our production efficiency is up by 35 per cent, cutting lead times from 7 days to just 48 hours. Factory throughput has increased by 40 per cent and our order fulfilment rate has hit 98 per cent, greatly improving customer satisfaction.”

Nitin explained that AI enables the company to monitor trends and consumer preferences in real time, allowing them to swiftly design and release new products. “We’ve managed to cut the time from concept to market by 50 per cent,” he said. As an example, he shared how AI predicted a growing demand for oversized fits among Gen Z consumers. By acting quickly on these insights, they fast-tracked production and launched the collection within two weeks, effectively capturing demand at its peak. “This agility has become essential to boosting sales and strengthening customer loyalty,” he noted.

| Today’s consumers are much more informed. They research products online before stepping into a store. This shift means that brands like ours need to move away from generic offerings and instead analyse customer behaviour and preferences to provide targeted, personalised experiences. Ranjan Sharma CIO and Head of Supply Chain, Bestseller India |

Minimising And Streamlining Return Handling

Handling clothing product returns is a critical challenge faced by fashion brands. Poor fit accounts for nearly 35 per cent of these returns, creating logistical complexities and financial losses for brands.

AI-based solutions mitigate these issues by offering personalised sizing recommendations, virtual try-ons, enhanced inventory management and warehouse optimisation. Several leading fashion brands are leveraging AI to address challenges related to product returns and enhance virtual fitting experiences.

For instance, Zalando, a leading German online retailer for fashion and footwear, employs AI to offer personalised size recommendations based on customer preferences and past purchases, ensuring a better fit andreducing returns.

Similarly, ASOS – a UK- based renowned fashion retailer – integrates AI-powered virtual fitting features, enabling shoppers to visualise how garments will look on different body types.

Even Nike is not behind as its innovative AI tool, Nike Fit, scans feet to recommend the perfect shoe size, minimising return rates drastically.

Meanwhile, Amazon Fashion uses AI tools like ‘Made for You’. Customers can use the Amazon app to measure their body by entering details such as their height, weight and body shape, along with uploading two photos.

The app’s ‘Made for You’ AI-based scanning technology then analyses this information to generate accurate body measurements for a personalised fit. This helps Amazon significantly reduce the return rate.

Another way of reducing returns using AI include Virtual Try-Ons and Fit Predictions. Online shoppers often find it difficult to determine if a particular product will suit their body type. For example, a person who typically wears an XXL shirt of Brand A may still find the same size of Brand B uncomfortable due to uneven body mass distribution. This often leads to abandoned shopping carts and missed sales opportunities for e-commerce brands.

Virtual styling tools, powered by computer vision and machine learning, show customers how items will fit and look before buying. These tools analyse past shopping habits, browsing patterns and preferences to suggest suitable products, improving the chances of sale and minimising returns.

AI for warehouse is a boon! Artificial Intelligence can streamline the reverse logistics process by analysing return data to predict trends/patterns in product returns. This data helps warehouses allocate resources more effectively such as designating specific zones for returned items or scheduling return processing during peak periods.

AI-powered tools can also automate the inspection and sorting of returned products. By quickly identifying the condition of returned items (whether they are resale- ready, require minor repairs or need to be scrapped), AI reduces manual effort and accelerates the restocking process. Since Returns data is integrated into inventory management systems, this allows warehouses to quickly adjust stock levels. For example, if a specific clothing size or style has a high return rate (overall or in a particular location), warehouses can hold on replenishing that item until further analysis is done.

AI-driven insights also help warehouses optimise space by identifying slow- moving or frequently returned items.

These insights can assist warehouses in making better stock placement strategies such as moving high-return items to easily accessible areas for quicker processing.

For brands that offer return pickups, AI can also optimise logistics by planning the most efficient routes for collection. This reduces fuel costs and speeds up the process, benefiting both the brand and the customer.

| AI can help reduce design iteration times in retail planning through Predictive Analytics and Consumer Insights; Generative Design and Prototyping; RealTime Feedback Loops; Automated Customisation and Personalisation; Optimised Supply Chain and Inventory Management; and Enhanced Visualisation Tools. Puneet Dudeja Director – Business Development, South Asia, WGSN |

Boosting Search Precision With AI Product Tagging

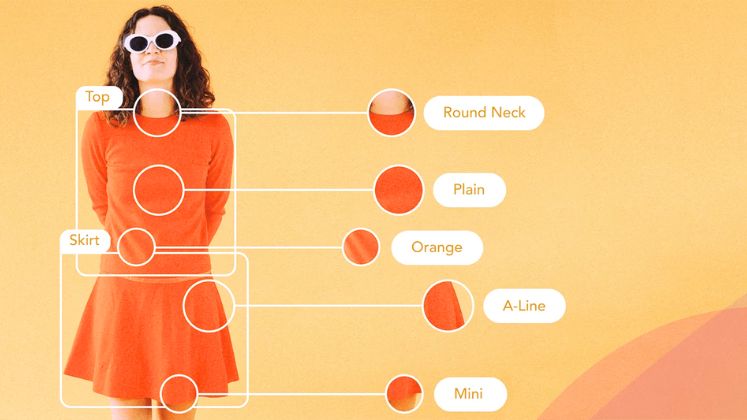

Imagine searching for ‘sweaters’ on an e-commerce platform andgetting products like shirts, trousers, jackets etc., in search result! Unstructured tagging of products in catalogues leads to broken searches on e-commerce platforms, making it difficult for customers to find what they are looking for. AI-based automatic product tagging generates accurate products, streamlining search results and improving product discoverability.

Zara employs AI to automatically tag products, ensuring accurate categorisation and refining the search process for customers. Similarly, ASOS uses AI-driven product tagging systems to improve search results by tagging items based on attributes like colour, size, style and material.

H&M also applies AI to streamline its product tagging, ensuring customers can find the exact items they are looking for with ease.

Macy’s utilises AI-powered product tagging to organise its inventory, optimising the search functionality for a smoother shopping experience. Uniqlo follows suit by implementing AI to categorise products effectively, enhancing search precision and speed.

In the Indian market, Myntra and Ajio utilise AI for product tagging to ensure better search functionality and categorisation on their e-commerce and app.

Streamoid, an AI tech partner for fashion retailers, offers a tool called Catalogix, which simplifies product cataloguing on e-commerce platforms. Catalogix automatically generates product attribute tags using advanced AI algorithms. This results in an 80 per cent reduction in training and management costs and significantly shortens time-to-market.

Catalogix integrates data from retailers’ various sources like ERP or Excel sheets using pre-built connectors. The AI then maps and transforms the data into accurate and consistent sets across the brand’s system. This process reduces time from 6 hours to just 6 minutes!

As Ranjan Sharma stated, “AI has enhanced how Bestseller India manages product discoverability. By using AI tools for content creation and SEO, we ensure that our products are well-tagged and easily searchable, streamlining our operations even before products arrive at distribution centres.”

Design Faster, Smarter With AI

AI is redefining fashion design by enabling creative teams to generate designs at an unprecedented scale and speed. AI is also helping factories in simplifying their design- to-production process as well as streamlining subsequent processes where design inputs are required.

Boosting Creativity in Retail Design

Creative directors and their teams can generate thousands of designs in no time today. With the integration of AI and Gen-AI tools into their design platforms, they simply need to input sketches and desired details – such as fabrics, colour palettes and textures etc. that automatically create an array of designs, thus allowing designers to play with an enormous variety of styles and looks. A team might then design new items based on these outputs. This opens the door to creating innovative product drops.

For instance, Hugo Boss integrated AI-driven 3D design into their process, which reduced their sampling time by 85 per cent. The global sportswear giant Nike utilises Browzwear’s 3D software, with AI integration, to streamline product development, reducing the need for physical samples and accelerating time-to-market. H&M leverages AI- based 3D design software to improve collaboration among design teams and suppliers, leading to faster and more sustainable product development.

AI has had a transformative impact on experimenting with diverse design styles, particularly in the field of CMF (Colour, Material, Finish) design. By leveraging AI tools like Midjourney, Stable Diffusion and DALL-E 2, creatives can explore a vast array of design possibilities that were previously unimaginable. The generative capabilities of these tools allow designers to rapidly visualise a multitude of CMF combinations, accelerating the conceptual phase and offering inspiration that might take weeks to develop manually.

According to Puneet Dudeja, Director – Business Development, South Asia, WGSN, AI can help reduce design iteration times in retail planning through Predictive Analytics and Consumer Insights; Generative Design and Prototyping; Real-Time Feedback Loops; Automated Customisation and in the AI Dreamscapes palette or the glowing marine-inspired tones in Shimmering Lagoon. These insights provide brands with a clear direction for their seasonal collections, ensuring their products stay aligned with consumer preferences.

AI-driven visualisation tools such as 3D rendering or virtual store layouts, also allow designers to quickly visualise how new products or store concepts will look in different settings.

Generative AI is transforming the fashion design process, offering better chances of success than traditional human-only design approaches, pointed out Amar Nagaram, Co- Founder, Virgio. “At Virgio, a recent collection was completed in just 18 days by combining generative AI with human creativity,” he said.

| While AI accelerates the design process and opens up vast creative possibilities, it still requires careful management. A well-defined strategy is essential to sift through the countless generated options and present the best concepts to stakeholders for decision-making. In essence, AI serves as a powerful tool for expanding the scope of design experimentation, providing endless combinations to explore, but it is not a replacement for the human touch in finalising manufacturable, market-ready products. |

Improving Efficiency in Manufacturing

Similarly, AI is making an impact on manufacturing processes. The ODD Factory, based in Mumbai, designs, manufactures and supplies apparel to brands and boutiques in India and internationally, with export markets in the USA, Australia, Dubai, Kuwait, Riyadh and Europe. The company recently launched an AI service that helps create fashion mood boards and print-ready files for brands. “Clients provide details like concepts, colours, target demographics and print ideas through a form. Based on this input, we deliver print-ready files and mood boards featuring 2D mock-ups of AI- generated designs, showcasing trends, patterns and colours,” said Turiya Kapoor, who leads Business Strategy and Finance at The ODD Factory.

Factories today can use AI tools to speed up Design-to-Production pipeline. AI bridges the gap between design and manufacturing by enabling faster prototyping and production readiness. For example designers can input sketches or ideas into AI tools to generate technical design files (like CADs) instantly.

These files can be directly used in automated cutting and sewing machines, reducing the time between concept and production.

Markedly, AI identifies potential flaws in design files before they reach production. For example, it can detect inconsistencies in patterns or stitching points that might cause issues in manufacturing.

AI also evaluates the practicality of designs based on production constraints, such as fabric availability, stitching complexity and machine capabilities. Manufacturers can focus on feasible designs, minimising production errors and waste.

Another use of AI-based fashion design tools in manufacturing is in mass customisation of designs. These tools enable manufacturers to cater to personalised designs at scale.

Using customer data such as body measurements and style preferences, AI can adapt patterns for individual production while maintaining efficiency in bulk manufacturing.

Triburg, a leading apparel sourcing solutions provider in India, too has significantly improved its design-to- production process with the help of AI. Sanjiv Kumar, Technical Head at Triburg, explained that they now create virtual samples in multiple options, such as full-length, knee- length and midi-length styles, in just one day. This allows customers to make quick and confident decisions. “In contrast, developing physical samples for the same options would take several days, potentially resulting in missed opportunities for certain styles,” mentioned Sanjiv. Triburg works with 46 apparel brands and 48 home brands, supported by a network of 500 factories.

AI has also brought greater precision to Triburg’s operations. For instance, while finalising CAD files, the team or clients can specify fit intentions—such as loose, oversized, regular or snug—directly within the file. This ensures the sketches align closely with the intended design.

| One of our clients noted a 75% reduction in turnaround time, enabling them to produce collections more frequently and respond quickly to market trends. The automation of tasks like grading and adjustments allows designers to focus more on creative aspects while maintaining consistency across patterns. Umesh Gaur MD (International), Tukatech |

Additionally, accurate information about technical trims is essential in CAD files and AI enables us to ensure this data is both precise and comprehensive. “Based on these critical parameters – fit intent and technical trims – our samples are developed with a high degree of accuracy, bringing us remarkably close to the original design intent,” added Sanjiv.

In many instances, Triburg receives orders for styles such as bias dresses or print placement designs. It is important to note that these styles cannot be accurately defined or finalised without first assessing their feasibility using AI tools, including 3D and 2D modelling.

For example, when working on a bias dress, Triburg’s product development team utilises AI to analyse whether the given fabric width can accommodate the required length of the style. “If necessary, we make pattern adjustments to ensure the design is production-feasible without of 3D technology with AI has further enhanced Triburg’s product development process. For instance, while developing certain styles for childrenswear the team has been able to automatically incorporate federal safety guidelines, including requirements for minimum stretch, seam strength and shrinkage.

“AI-driven tools allow us to simulate fabric behaviour, test structural integrity and assess performance parameters in real time,” averred Sanjiv.

In a similar vein, Umesh Gaur, MD (International), Tukatech, which provides both design software and hardware solutions, helping businesses of all sizes, highlights the impact of AI in accelerating the design-to- production pipeline. By incorporating AI in the company’s Automatic Pattern Making (APM) and TUKA3D tools, factories have seen significant reductions in the time it takes to convert concepts into production-ready designs. For instance, tasks like pattern development, which once took days, can now be completed in just minutes.

“One of our clients noted a 75 per cent reduction in turnaround time, enabling them to produce collections more frequently and respond quickly to market trends. The automation of tasks like grading and adjustments allows designers to focus more on creative aspects while maintaining consistency across patterns,” commented Umesh.

AI tools have also improved the accuracy of design-ready files such as CADs. TUKATECH’s master block patterns, available on the TUKAweb Marketplace, ensure that designers start with a solid foundation, reducing errors down the line. Key parameters, including seam allowances, dart placements and fit measurements, are optimised through AI-driven algorithms, minimising the need for manual corrections.

For example, one garment manufacturing client in India, utilising TUKA3D, reported a 98 per cent accuracy rate in their initial CAD designs, significantly reducing the need for sample iterations and minimising waste, as claimed by Umesh.

TUKATECH’s AI-driven systems ensure that designs are not only creative but also feasible for production. With TUKA3D, designers can simulate garments on virtual avatars, identifying potential fit or construction issues before fabric is even cut.

“A brand using TUKA3D to simulate complex drapery designs found that the AI flagged potential stress points and suggested adjustments, resulting in a 20 per cent reduction in material waste. Testing and refining designs digitally has proven invaluable in aligning creative vision with practical production,” asserted Umesh.

Similarly, Dave Kart, VP, Marketing, Browzwear, which provides providing 3D apparel design software for the fashion industry, apparel product development and merchandising solutions, highlighted that one of their clients utilised AI to create 24 new colourways for a single garment, reducing over 100 hours of manual effort. By integrating AI with digital product creation tools and product lifecycle management (PLM) systems, brands can generate and share tech packs with factories, ensuring accuracy and reducing back-and-forth revisions.

One of the learnings Browzwear found is that applying GenAI to apparel design is not nearly as effective as applying a model that is tailored to particular needs and trained with brands’ data, their standards, branding and libraries of garments, fabrics, etc. “You can only achieve effective AI by aggregating disparate data sets,” commented Dave.

| Through IoT-based sensors that Smartex provides, factories can capture realtime defect data, enabling them to identify a wide array of issues that might otherwise go unnoticed by the human eye. These defects include elastane dashes, sinker issues, oil stains, broken elastane, irregular yarn thickness, needle problems and more, paving the way for in-depth analysis and superior quality control. Giberto Loureiro Co-Founder, Smartex |

AI Redefining Predictive Maintenance

In apparel and textile manufacturing, AI is used in predictive maintenance of cutting machines, sewing machines and knitting machines. The machines that can be integrated with AI-enabled sensors predict any possible breakdown.

In case of cutting machines, these breakdowns include knife breakage and bearing failures etc.; while in case of sewing machines, these breakdowns include thread snapping, part misalignment, lubrication level and motor burnout.

All major cutting technology companies like Lectra, Morgan Tecnica, IMA, Eastman and Bullmer are using predictive maintenance concept in their cutters. For example, Eastman uses synchronised technology which digitises the motion control totally.

If something is starting to break or not working well, Eastman’s machines show a warning on the monitor ahead of time, so users know to replace the part. This system, called Robotic Indication System (ROI), automatically detects problems like loose wires and highlights them on the monitor.

In addition, artificial intelligence (AI) and machine learning are being used to make cutting machines even more reliable and advanced. For instance, the blade, which is a key part of the machine, is now monitored by AI. The machine can tell how long the blade will last based on the type of production and this is predicted by collecting data from the machine’s usage.

More interestingly, once some concrete information from machines is collected, the cutting tech companies like Lectra can prepare a ‘Maintenance Kit’ which is directly supplied to the customers’ place without letting them know and this whole process is known as ‘automatic refurbishment’. The company automatically delivers its customers those parts which they are using the most, based on the analysed data and they don’t need to place orders.

“Through IoT-based sensors that Smartex provides, factories can capture real-time defect data, enabling them to identify a wide array of issues that might otherwise go unnoticed by the human eye. These defects include elastane dashes, sinker issues, oil stains, broken elastane, irregular yarn thickness, needle problems and more, paving the way for in-depth analysis and superior quality control,” commented Giberto Loureiro, Co-Founder, Smartex – a promising AI-based smart technology provider for textile industry.

It’s worth mentioning here that this prediction is done by collecting maintenance data and production data of the machines based on which it can be identified if factory equipment are used on an optimal level or not!

Similarly, with the help of AI-enabled Automated Storage Systems, the warehouses can monitor conveyors, sorters and automated picking systems, predicting malfunctions and reducing disruptions in inventory management.

For example, AI-powered visual inspection systems are transforming warehouse operations, argues, Chetan Daga, Senior Consultant, Argon & Co. These systems utilise high- resolution cameras and advanced algorithms to monitor products on conveyor belts, ensuring they are correctly packed with the right inventory. Defective items are identified and sorted out, allowing only compliant products to proceed.

“The cameras capture detailed images of each product, even at high speeds, while computer vision algorithms analyse them for defects like incorrect packing, missing items or damage. Products are then categorised as compliant or defective based on this analysis,” mentioned Chetan.

AI-Powered Precision In Visual Inspection And Quality Control

Visual inspection of finished garments has long been a challenge for factories producing in bulk. AI-powered machines, like the one from Dongguan Yunji Zhihui Technology Co., Ltd., a China-based high-tech industrial intelligent equipment developer and technical service provider, streamline the process with automated measurement capabilities.

For instance, when measuring a T-shirt, the machine detects the dimensions of its uncovered areas while it is laid flat.

Within seconds, the machine displays a Pass/Fail message on the screen, along with all measurements. It accurately assesses garment dimensions, identifies errors and calculates deviations that are automatically fed into the system. These machines also recognise product details and generate comprehensive quality reports, simplifying operations for apparel factories. The machine has an error margin of just ±1mm, compared to the 5mm error in manual measurements. It can measure each piece in as little as 6 seconds.

“We developed our first product specifically for the clothing industry in China and are optimistic about expanding to international markets like India and Bangladesh,” shared Sky Jia, General Manager, Dongguan Yunji Zhihui Technology Co., Ltd.

Another use of AI in quality monitoring is proving to be a game changer for factories. AI-powered tools analyse historical shop floor production data to identify patterns and predict defects in operations or products. By examining attributes like machine usage, personnel performance, and process efficiency, these systems can foresee up to 80 per cent of potential defects in real-time.

Avanti Overseas, a textile toy manufacturer in Noida, India, is using AI to improve quality checks before fibre filling. This system has helped reduce the defect rate from over 15 per cent with manual inspections to less than 3 per cent. Raghav Modi, Managing Director, Avanti Overseas, said, “With AI-powered real-time quality inspection, we’ve made huge improvements in quality control. The tablet system from STITCH gives instant updates on approved, rejected and changed products, making the inspection process much smoother.”

AI Enhancing Fabric Inspection For Flawless Textiles

AI tools for fabric defect inspection use advanced computer vision, machine learning and automated systems to analyse fabrics with precision. High- resolution cameras and sensors capture detailed images or videos of fabrics, which are then analysed in real time by AI algorithms trained to detect defects like tears, colour mismatches and weaving irregularities.

These systems classify and map defects, generating detailed reports that include type, size and location for production planning. Historical data is stored to identify recurring issues and optimise quality control processes. Additionally, automated feedback loops allow weaving or dyeing machines to adjust in real-time, minimising defects and enhancing overall production efficiency.

While fabric defect detection technology has been around for years, only a few companies have moved beyond traditional methods to adopt AI-driven solutions for fabric inspection.

One such pioneer is Bullmer, among the first to introduce the next- generation AI-powered technology— AI 01—for fabric inspection. As a global leader in automatic cutting equipment, Bullmer, a Germany- based subsidiary of China’s Jack Stock, has established a dedicated AI fabric inspection team in Shenzhen, China. Its advanced technology addresses key challenges in the apparel and textile industries such as high defect rates, increased compensation costs and the limitations of manual defect recognition.