Finding technology that is adaptive to existing machinery is a troublesome task, as each piece of appliance has its own software or platform that it works on, which may or may not interact with another format. This causes trouble in the cutting room, where there are multiple tasks that need to be accomplished which can all be automated, and would need minimum possible human involvement. With the aim of setting up complete cutting rooms, rather than just dealing in spreaders and cutters, in an interview with Team StitchWorld, Serkon Makina proposes to the industry the concept of automated and fully interactive cutting rooms.

Purchasing an automatic spreader or a CNC cutter is an important decision for any apparel manufacturer as it takes into account a huge financial investment. Once the decision is made, then comes the search for the perfect machine that would be compatible with all other technologies which have been pre-installed in the manufacturing setup. That’s where Turkey’s leading company Serkon Makina comes to the rescue with their cutting room arrangements.

With major market share from Bangladesh, Vietnam and Indonesia, Serkon Makina, is paving its footprint in India also through Tirupur and Kolkata with plans to enter the Delhi and Bombay markets also. An ISO 9001:2008 and OHSAS 18001:2007 certified company, Serkon Makina deals in wide variety of applications for garment setups, specifically: cutting rooms, pin tables, software, hanger systems, computerized tables and air tables. The company specializes in wide width spreaders for home textiles, facilitating a width of 3.4 metres, a rarity from brands developing automatic spreaders. It already has a wide-spread market in Europe and is looking forward to setting up offices in Asia and South America in the coming years.

While talking to SW, Burak Uysal, Sales and Marketing Coordinator for Serkon Makina informs, “We are quite flexible, in terms of application. We make smaller machines and new software for our customers, both of which are customized for each client. Reasonable prices make us very much competitive with other suppliers, even though we make our machines, the software and the hardware in Turkey.”

Working through various agents in different countries – Nhat Tin Technology J.S.C in Vietnam, Texcom Autocrafts Ltd. in Bangladesh, Centra Java in Indonesia, and Rainbow Garment Machines in India, the company’s main focus is on servicing the industry for which it trains technicians to provide effective and responsive services to their customers, as the machines would require constant maintenance and have critical consumable parts which are not always readily available in the market.

According to N. Senthil Kumar, Managing Director of Rainbow Garment Machines, one of the machine agents for Serkon in India, “Everyone in the apparel industry is looking for automation due to increasing labour wages and to attain better quality a machine can provide. The company will focus on marketing cutting solutions and machines in India, and will soon cover the whole Southern area of India,” adding, “A big selling point for any machinery is the post-sales services that a company provides, a fact that Serkon Makina takes pride in, and along with a great marketing strategy, the company can capture the market in India in 2-3 years.”

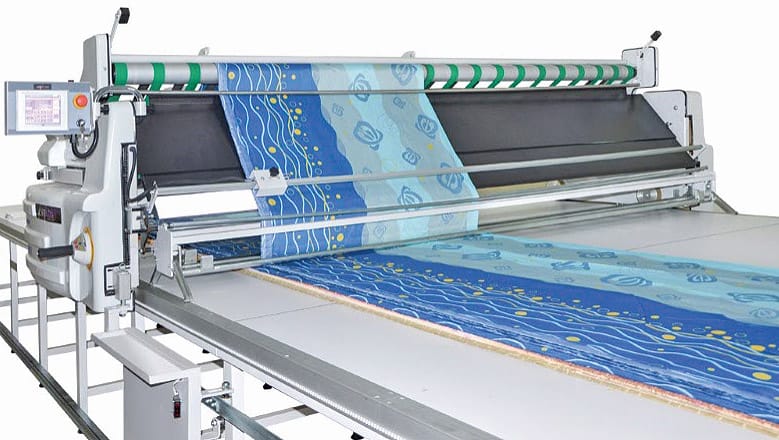

MH 1, a 3.4 m wide fully automatic fabric spreader for home textiles

Fully automatic fabric spreading machine Master Home Textile MH 1 operates at the spreading speed of 100 metres/minute and has a spreading height of 0.25 metres with cutting device. This automatic spreader has a table width ranging from 2.8 metres to 3.6 metres with allowed fabric width available from 2.6 metres to 3.4 metre. It can handle roll diameter of 0.65 metres. Besides this, the machine can spread woven and knit fabrics in roll or flat-fold form weighing up to 300 kgs without tension and edges are aligned perfectly. The cradle feed system tilts for easy fabric roll loading/unloading and eliminates the use of a fabric roll bar. Its multi-function throttle enables the operator to control threading or rewinding of fabric.

Capable of operating at the speed of 100 m/min with a cutting height of up to 90 cm, the MH 1 for home textiles has a cutting width ranging from 1.6 metres to 2.4 metres, viable for wide fabrics used in manufacturing home furnishings. Integrated with Windows platform, the machine is compatible with all CAD systems and can select the pieces not to be cut and bypass them during cutting.

The operator can control the spreading with one hand while riding alongside the table. The electronic edge control is responsive to variable speed at forward/backward turns, thus saving time. In a case of emergency, it stops automatically with the help of safety sensors. Apart from multi-length spreading modes with ply counter, it allows the automatic pre-centring of material beginning during threading. The simplified LCD touchscreen display with PLC unit is quick to learn, storing 50 different fabric set up files for quick retrieval to accelerate future spreading jobs available in Turkish, English and other foreign languages.

Automatic Fabric Cutters

Automatic fabric cutters are provided in a range of 3 models – MC 50-30, MC 80-70 and MC 90, which are the latest addition to the cutting machines’ collection.

MC 90 cuts at the speed of 100 m/min

Other than just being ‘quiet’ machines, with the noise level below 80 dBA, MC 90 provides the best features of CNC cutter. Operating at the speed of 100 m/min with a cutting height up to 0.09 metres, this automatic cutter has a cutting width available from 1.6 metres to 2.4 metres. Integrated with Windows platform, MC 90 is compatible with all CAD systems and can select the pieces not to be cut and bypass them during cutting.

Allowing different cutting options like butterfly, mixed-cut, clockwise and anticlockwise, it can be displaced crosswise. It has the ability to manage, convert and transform all kinds of notches, i.e. normal, V-notch and fly notch, allowing the operator to change the bite size, if needed. A re-sealer can be used to avoid vacuum losses.

The blower system holds the material firmly in place during the cutting process delivering cut parts that are accurate to ply. The blade monitoring system detects the abrasion of the blade and automatically stops working needing replacement. It can change the radius of patterns at corners, suggesting that the knife goes up if there is a sharp corner which eventually increases the cutting quality and is considered a very efficient feature for suit manufacturers. It resumes cutting from hibernation if any kind of disturbance persists.

MC 80-70 with Intelligent Knife System

This special CNC operates at the speed of 80 m/min with a cutting height up to 0.08 metres. The fabric cutting width available is from 1.6 metres to 2.6 metres. MC 80-70 comes with an intelligent knife system which senses deflection of the knife while cutting high-ply spreads and changes the knife angle to compensate for the deflection. It results in more accurately cut parts and nest parts closer together to achieve outstanding material utilization. The Lateral Travel Kit in this CNC cutter enables the cutter to move between multiple spreading tables. MC 80-70 is designed to cool down the knife with a vortex tube to reduce fusing between plies while cutting.

MC 80-70 CNC cutter fabric is incorporated with an Intelligent Knife System which senses deflection of the knife while cutting high-ply spreads and changes the knife’s angle to compensate for the deflection. Common for all automatic cutters of Serkon Makina, there is a user-friendly keypad which controls many machine’s functions at the cutter.

MC 50-30 cuts ply height as low as 0.03 metre

Conveyorized automatic fabric cutting machine MC 50-30 cuts at the speed of 80 m/min with a cutting height of 0.03 m-0.05 m. The fabric cutting width available is from 1.6 metres to 2.8 metres. Its long lasting bristles allow the knife to penetrate without damaging the fabric. Ensuring quality in cut parts from top to bottom ply, its automatic knife re-sharpening eliminates hanging threads. The machine includes a user-friendly keypad which controls functioning of the cutting head. Additionally, software and operating manuals are available in Turkish, English and other foreign languages.

Manufacturing the machines in Europe ensures the quality of the parts and guarantees that the product parts will not fail untimely. The company has already installed two full cutting rooms and will exhibit the same as the showroom for other perspective clients. Their reasonable pricing and the ability to customize their products give this company an edge over others in Indian market!