Despite great strides in manufacturing achieved by the automobile and aviation industry in recent times, apparel manufacturing units remain unchanged, somehow, as far as complete automated production is concerned. However, automated apparel production has started to be implemented across the globe and has moved from the US to the other side of the Pacific where low labour costs help to meet the consumer demands for more inexpensive goods. According to a study by the United States Fashion Industry Association, 43% of American fashion companies believe that rising production, labour and sourcing costs are some of the most difficult business challenges. In the same context, Pete Santora, Chief Commercial Officer, SoftWear Automation, and Dr. Mike Fralix, CEO, [TC]2, Technology Evangelist, SoftWear Automation (USA) explain how automation in garment manufacturing would create a revolution never seen before.

How do you think Robotics will impact sewing technology in the coming years?

Robotic technology for the sewn products industry was developed in the US in the 1990s as a strategy to help companies compete with the increasing cost of labour. Unfortunately, such developments were abandoned because producing offshore in low-cost labour countries was less expensive overall. As a result, the current sewing technology has been developed assuming that human operators are required.

There are at least three key issues/glitches with the current apparel manufacturing supply chain strategy.

1. The cost of labour and the cost of transportation have continued to increase to such a point that there are not many cheap-labour countries left. And, those which are there do not have the necessary infrastructure in place to meet the needs of U.S. brands and retailers.

2. The global supply chain has become expansive and very complex. This complexity requires high inventory, more accurate forecasting and additional financing in order to produce quality goods on time. Unfortunately, the existing system fails quite often because of prevalent issues like weather systems, Government policy changes, G20 summits, smog control, labour wage changes, shipping, and customs’ issues. A lot of things have to be right to receive products on a regular/timely basis. As a result, several resources are consumed on forecasting properly, financing the inventory, and then storing that inventory.

3. Most new products are still very slow to get to the market. Market share of global brands is being eroded by very quick and nimble start-up companies who have customer loyalty. And, with low-cost labour controlling manufacturing, improvements in speed, efficiency, and innovation have been slower than they might otherwise have been.

The robotic systems that were put on the shelf in the 1990s are now being replaced by more sophisticated technology and companies which are now rethinking their sourcing strategies. As robotic technology is implemented on the manufacturing floor and cheap labour is removed as a barrier, this generation of automation will radically change the cost, capabilities, selection, availability and ultimately, the location of where the goods are produced.

Apparel manufacturing has been very labour-intensive, it has always pushed jobs to the cheapest provider of goods. However, with the changing time, as manufacturing and retail overlap, the ability to produce garments at the time they are ordered will affect the sourcing decisions.

I understand Robotics (or complete automation) was attempted during early ’90s (across several developed countries) but failed. What went wrong that time? Why do you think robotic sewing will succeed this time?

There were two key issues with automation in the ’90s.

1. The robotic systems that were developed never completely automated sewing. Some jobs were automated very effectively; however, fabric distortion was too difficult for older generations of computing. For many fabrics, it was difficult to stiffen or hold the material fast enough to sew it without people. With the passage of time and introduction of Moore’s law, there is now sufficient computing power available to deal with these problems in real-time.

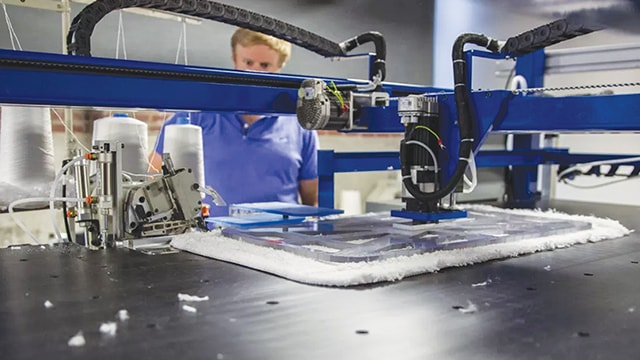

At SoftWear Automation, the fabric distortion can be recognized in real-time and then Robotics can be used to move the fabric into place between each needle strike. This technology looks more like an autonomous driving car than standard automation. This could not be done in the ’90s.

2. Automation in the ’90s was hardware-based and whenever there was a style change or material change, the line had to be retooled. The cost of retooling negatively impacted automation, made it difficult to achieve total automation and low-cost labour became a simple and easy alternative.

For a company like SoftWear Automation, the advancements are seen in software, machine vision, and machine learning. This allows for flexibility across different styles, materials, and weights without retooling and without additional costs. This introduces the concept of product portfolio automation rather than just operation automation.

What are the current challenges of robotic sewing?

One of robotic sewing’s biggest challenge is the ability to handle variations in fabric properties. Lighter weight fabrics can be more difficult to control than heavier/stiffer fabrics. With Industry 4.0, and machines talking directly to machines, fabric properties will be automatically communicated to robotic sewing systems and the necessary adjustments will be made to the entire assembly line.

Another challenge is the ability to sew different styles of the same fabric. Again, Industry 4.0, with machines talking directly to people, will be used to communicate style changes so that reprogramming of the robotic line will take place automatically and without stopping the production line.

In addition, designers don’t currently design with automation in mind. They create an almost endless sea of versions, styles and customizations. What’s interesting about Fast Fashion is that although the products that are developed change rapidly, a lot of them are based on the same basic technical blocks. This is what makes Fast Fashion and robotic automation a great future couple.

Why do you think any manufacturer will go for robotic sewing? Is it because of quality and consistency? Will it reduce the dependency on low-cost labour (reshoring?) Do you think there are enough reasons to opt for this? What kind of merchandise will be the initial targets to be produced by robotic sewing? Will they be commodities or luxury items?

The argument which commonly prevails is that brands, retailers, and manufacturers should be more concerned about quality and consistency than about cost. But unfortunately, cost has been historically the controlling factor and it will always be the key driver for Robotics. Because apparel manufacturing has been very labour intensive, it has always pushed jobs to the cheapest provider of goods. However, with the changing time, as manufacturing and retail overlap, the ability to produce garments at the time they are ordered will affect the sourcing decisions. This changes our understanding of how manufacturing will be used as a sales tool both at the store and in the shopping cart.

The first target for robotic sewing will be commodities and garments that have a limited number of operations. T-Shirts are a logical choice because they are in high demand and they are made from fabrics that are difficult to handle automatically. After solving the fabric handling of very lightweight material, adjustments can henceforth be made to sew almost any other fabric. And, after developing a completely automated robotic production line for a basic product, additional operations can be added.

Which companies are progressively pursuing Robotics in sewing, and what have they achieved?

Many companies today are showing growing interest in robotic sewing. The increasing cost of labour has resulted in companies of Bangladesh, China, India, Russia, Singapore, Taiwan, and others requesting for more information on the latest developments at SoftWear Automation. This is in addition to the companies across the United States, Mexico, Central America, and Europe. Everyone who hears about Robotics in sewing wants to know more. The list is truly extensive.

In terms of what they have achieved, they have been able to reach and exist in regions of the world which have limited economic resources. And they will be further able to acquire large new orders and customers by demonstrating their commitment to the future.

So it’s important to understand that Robotics isn’t just about the cost of automation vs. the cost of labour. Before long, the cost of robotic automation will come down. And, at present, it represents a moment in time for the competitive landscape to change. How often does an industry get a chance to affect trillions of dollars in purchase orders and disrupt the status quo buying behaviour of brands? It hasn’t happened for many years at this scale.