It’s not just what’s inside the box that matters anymore, it’s the box itself!

As more fashion brands embrace sustainability, they’re facing a hard truth. You can’t claim to be eco-friendly and still wrap your conscious collection in plastic that lingers for centuries. A linen dress made with care loses its charm when it arrives smothered in cling wrap.

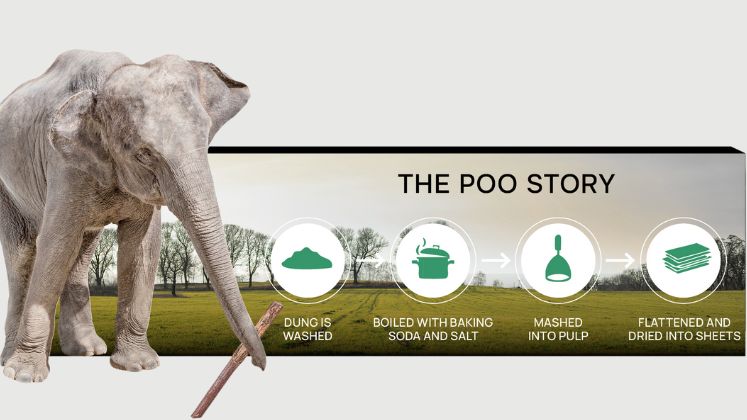

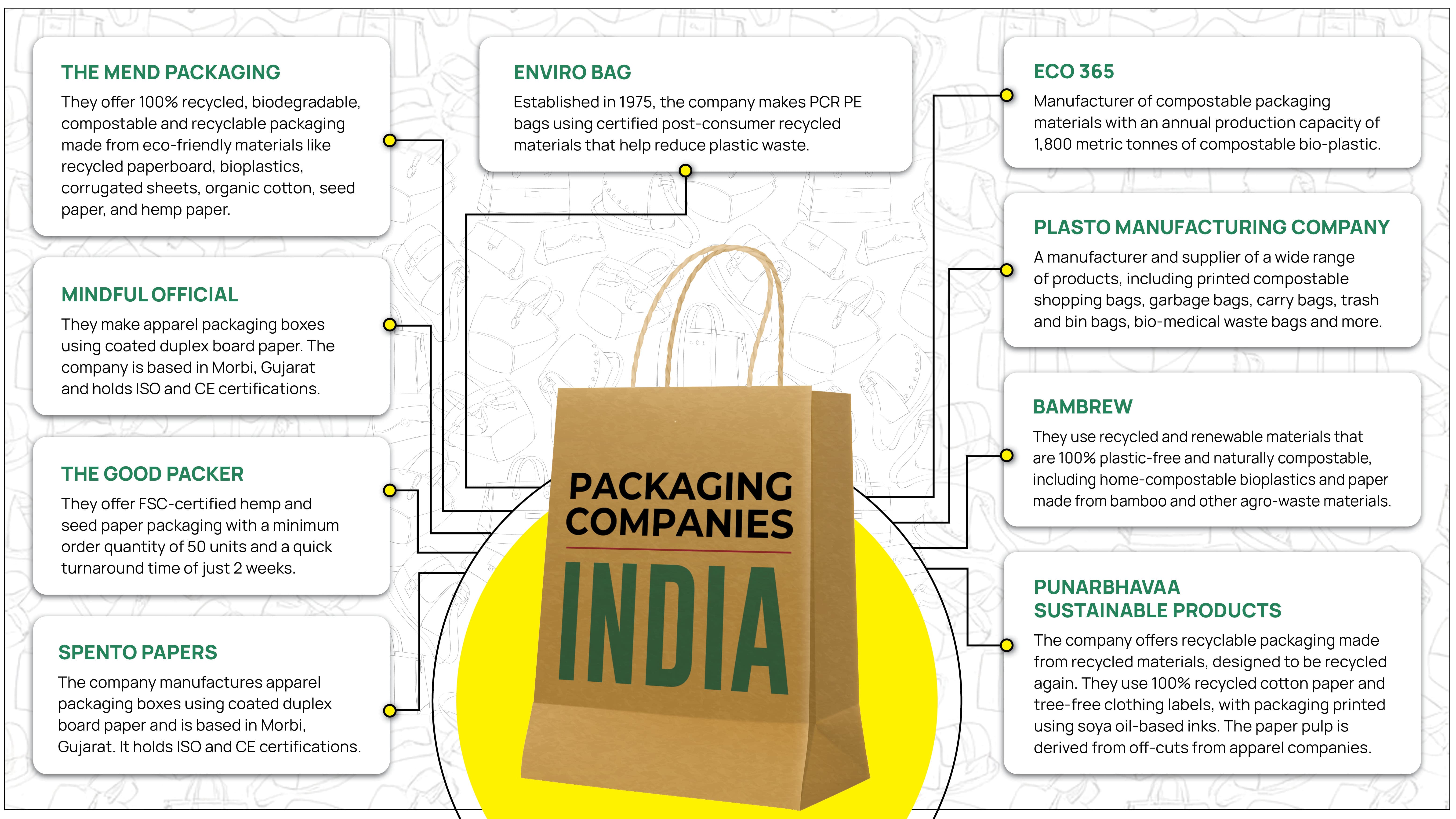

That’s why packaging is getting a much-needed upgrade. From compostable cornstarch pouches to paper made from elephant poo, the industry is proving that sustainability doesn’t end at the stitch. It carries through to the tag, the tape and the bag it all comes in.

The shift is necessary. After all, the fashion industry uses around 180 billion plastic poly bags every year. Less than 15 per cent of those get recycled. That’s why both consumers and policymakers are pushing for change.

For example, in the UK, the Plastic Packaging Tax means companies pay extra if their packaging doesn’t include at least 30 per cent recycled plastic. Across the EU, new rules aim to ensure all packaging is recyclable or reusable by 2030. The German Packaging Act (VerpackG) encourages brands to use eco-friendly materials with financial incentives. In the US, many states are banning single-use plastics, setting waste reduction goals and introducing laws that make producers responsible for their packaging waste.

India is taking action too. The Environment Ministry has introduced a draft of the Environment Protection (Extended Producer Responsibility for Packaging) Rules, 2024. These rules were notified in December 2025 and are set to come into effect from April 1, 2026.

The proposed regulations focus on Extended Producer Responsibility (EPR), which means producers, importers and brand owners (PIBOs) will be responsible for the entire lifecycle of packaging materials. This includes paper, glass, metal and even sanitary products. From production to recycling and disposal, PIBOs will need to manage packaging waste sustainably.

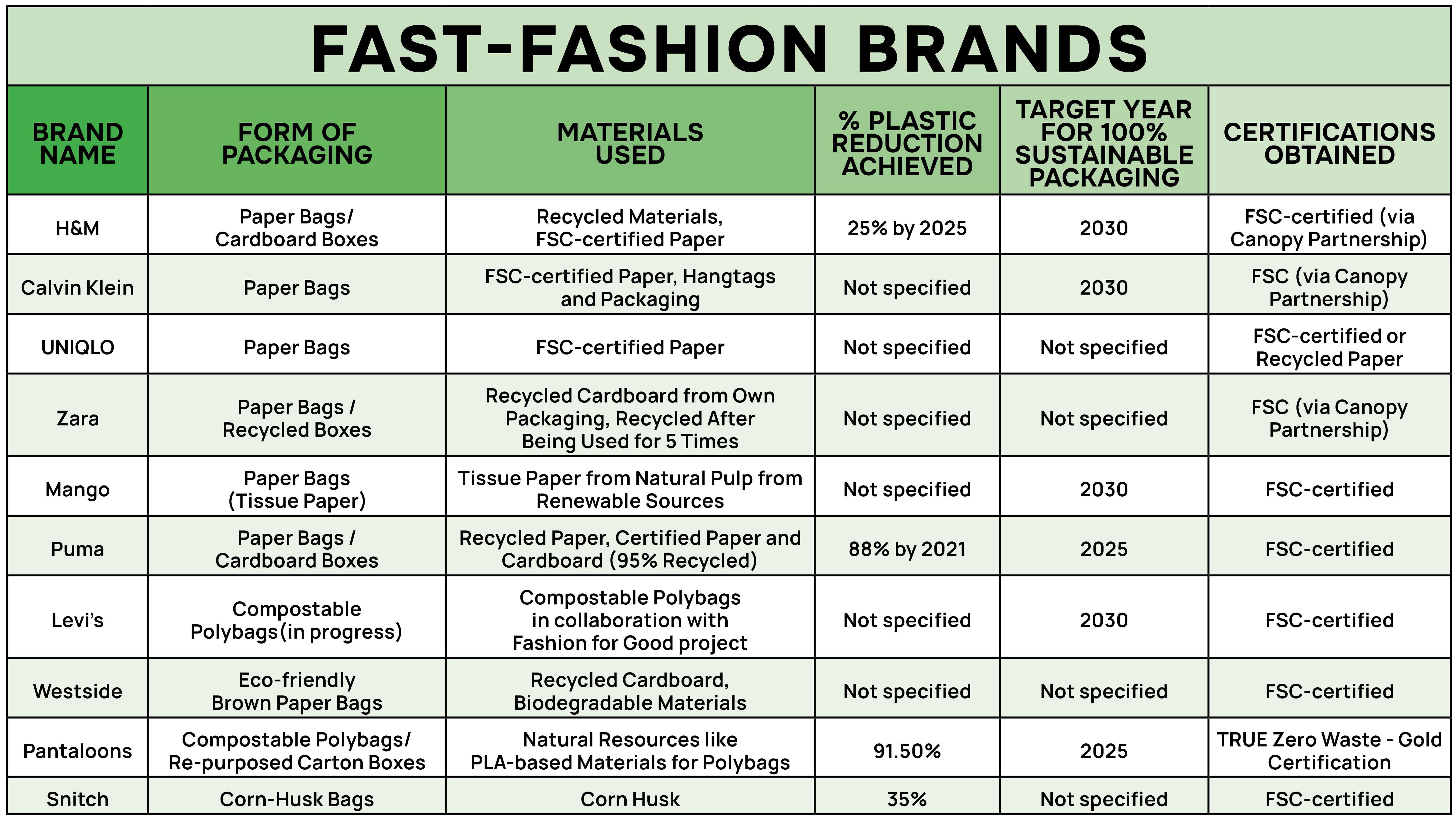

Slow fashion brands have already been leading the way, but now even fast fashion companies and big retailers are starting to step up. Levi’s, for example, has banned PVC (Polyvinyl chloride) from its products. Its polybags are now either compostable, recyclable or made from recycled materials. It is also testing new bio-based alternatives through the Fashion for Good initiative and has shrank its paper hang tags.

| INDIA IS TAKING ACTION TOO

The Environment Ministry has introduced a draft of the Environment Protection (Extended Producer Responsibility for Packaging) Rules, 2024. These rules were notified in December 2025 and are set to come into effect from April 1, 2026. |

Similarly, Fast Retailing, the Japanese company behind UNIQLO, took action back in 2019. It created a group-wide policy to remove unnecessary plastic across its entire supply chain. It has replaced plastic shopping bags with ones made from FSC-certified or recycled paper.

H&M is also making big moves. Most of its packaging now uses paper and cardboard from FSC-certified sources. And it has already reduced its plastic packaging by 54 per cent compared to 2018, beating its 2025 goal ahead of time.

Zara is also a part of the movement. The brand has committed to cutting out any packaging that doesn’t meet stringent environmental standards. That means no paper or cardboard unless it’s FSC-certified. If that’s not possible, the next best alternative must at least be to meet the PEFC (Programme for the Endorsement of Forest Certification) or FLEGT (Forest Law Enforcement, Governance and Trade) standards.

Others are pushing ahead in their own ways. Calvin Klein, for example, has partnered with Canopy to ensure all its paper tags and packaging materials are FSC-certified. Mango is aiming to eliminate 160 million plastic bags a year from its supply chain by switching to tissue paper made from responsibly managed forests.

As of 2021, Puma had already reached 88 per cent of its goal to use certified or recycled paper and cardboard in its packaging. Its store bags, hang tags and even shoe boxes are FSC-certified, with the boxes made from over 95 per cent recycled content.

Indian brands and retailers are stepping into the conversation too. Snitch has embraced corn husk-based packaging, cutting down plastic use by 35 per cent. Westside uses paper bags made from recycled materials. And at Pantaloons, over six lakh cartons were reused last year, keeping them out of landfills.

Deadline for 100% Sustainability

Many of these brands have also set deadlines to achieve 100 per cent sustainability in their packaging practices.

Levi Strauss, for instance, has committed to eliminating single-use plastics in all consumer-facing packaging by 2030, aiming for a complete shift to reusable, recyclable or home-compostable materials.

H&M has laid out several goals aligned with its broader climate and circularity strategy. This includes an absolute plastic packaging reduction of 25 per cent by 2025 using 2018 as a baseline, designing 100 per cent of its packaging to be recyclable or reusable by 2025 and ensuring all packaging materials are made from recycled or sustainably sourced materials by 2030, prioritising post-consumer recycled materials. The brand also plans to reuse or recycle all packaging from its own sites by 2025.

Whereas, Puma has pledged to use 100 per cent certified or recycled paper and cardboard by 2025.

Closer to home, the Pantaloons store chain reported achieving 88 per cent sustainable packaging by FY 2021 and is targeting full sustainability by 2025.

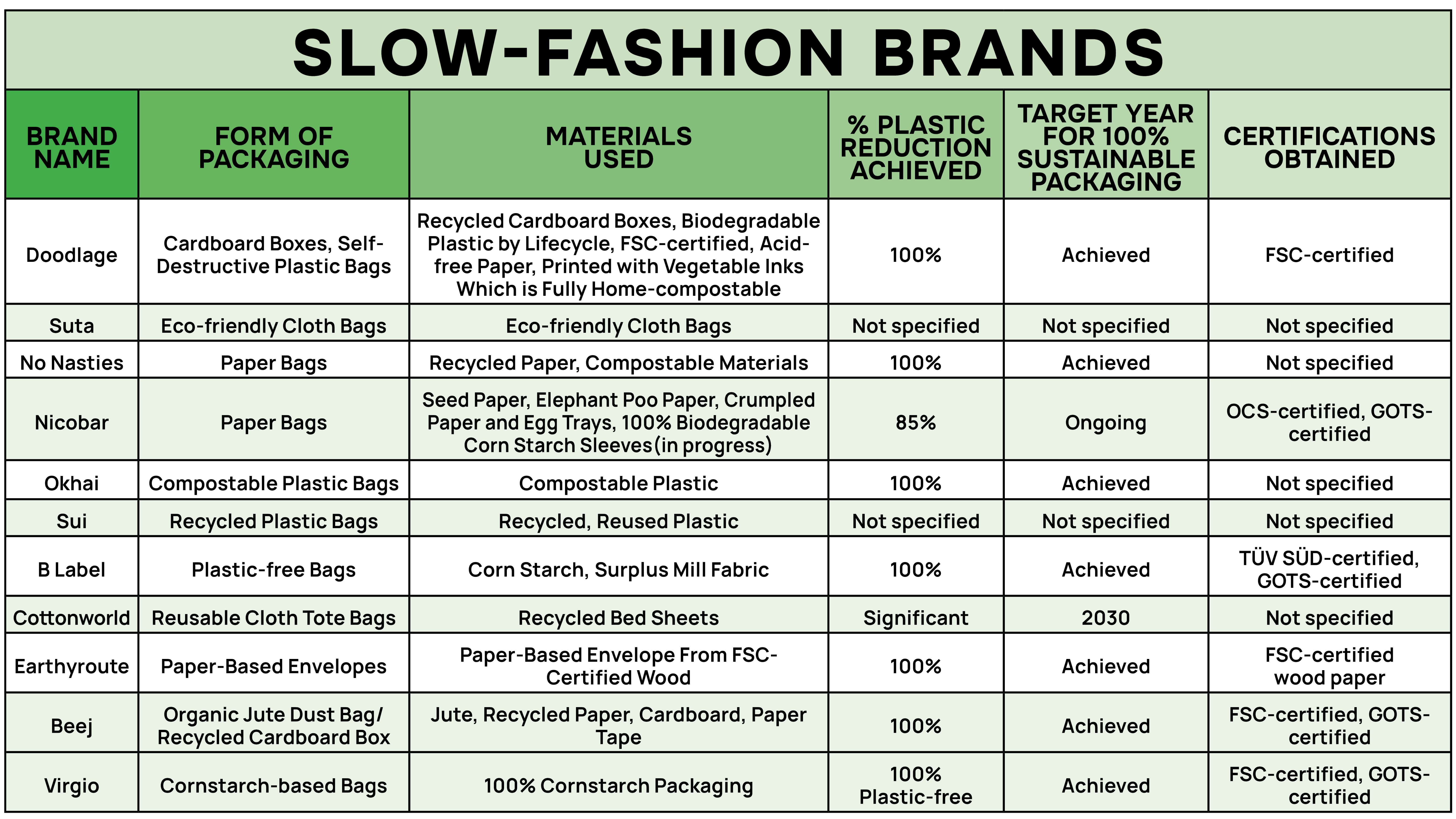

Slow Fashion Leading with Innovation

Some of the most innovative solutions are coming from homegrown and independent labels. For example, Doodlage has collaborated with Lyfecycle to create bags that turn into eco-friendly wax, which fungi and bacteria treat as food, breaking it down and returning it to the earth within just two years. This process, called ‘biotransformation’, is based on new technology developed by scientists at Imperial College London.

Similarly, Suta has overhauled its internal packaging process. When stock arrives at its Kolkata centres, plastic is carefully unwrapped and reused. For customers, Suta sends sarees and other products in eco-friendly cloth bags that can be reused. No Nasties, on the other hand, claims that all its Indian orders are shipped in recycled and compostable packaging. Nicobar has reduced its plastic packaging by 85 per cent, replacing air or foam pouches with crumpled paper and egg trays. It also uses seed and elephant poo paper for product tags instead of paper from trees and has jewellery pouches made from fully biodegradable fabric, intended for repurposing.

Moreover, Nicobar is producing 100 per cent biodegradable corn starch sleeves. Okhai also offers biodegradable packaging, using recycled materials wherever possible and striving to make its packaging plastic-free. Similarly, Sui works to upcycle fabric scraps and reuse/recycle any plastic it uses to keep it in the system.

B Label uses 100 per cent plastic-free packaging, with products wrapped in two layers of packaging: a multi-functional travel organiser made from surplus mill fabric and an outer layer made from biodegradable corn starch that is home compostable and recyclable.

Cottonworld too has switched to eco-friendly, reusable cloth tote bags made from recycled bed sheets. Earthy Route’s sleek paper-based envelope is made from FSC-certified wood, which can be reused and composted. Beej follows a strict plastic-free and zero-waste packaging policy, using organic jute dust bags and corrugated recyclable boxes for its products. While some external plastic packaging may be used by delivery partners, Beej says it is working towards minimising that as well.

In addition, Virgio uses packaging made entirely from corn starch, which is fully biodegradable. In the fashion industry, it seems plastic has finally got the memo!