Keeping up with its strategic objectives of continuous improvement, it was felt all across the Brandix business processes to reduce the fabric inventory days and realize higher savings. The Brandix Process Improvement Team, in conjunction with the Brandix Operational Finance Division, set out to bring down the inventory days across various business processes at Brandix Casualwear to an acceptably sustainable level, reports Amila Nandasekera, Process Improvement Specialist in Brandix Lanka Ltd.

Quality performance” is the foundation stone for any industry and Six Sigma is a systematical process of “quality improvement” through a disciplined data-analyzing approach. Through its implementation, it is being made sure that the goals are set on the improvement of all processes to reach the level of better quality. For the Brandix Group in Sri Lanka, a need of reduction of inventory days was felt all across their business processes. Inventory management was one key area where much of the savings could be realized. In order to attain these very fundamental objectives, Six Sigma methodology was implemented, through Define, Measure, Analyze, Improve and Control (DMAIC) methodology which is used to improve an existing business process. Another methodology, the Define, Measure, Analyze, Design and Verify (DMADV) is used to create new product or process designs.

![]() Brandix, a front runner in Sri Lanka, has initiated many improvement projects in its various factories. Brandix Casualwear (BCW) one among many Brandix garment units, manufacturer of woven bottoms, basic pants, cargo pants, jeans, and shorts was the first company to be chosen to reduce the fabric holding time from fabric in-house to Planned Cut Date (PCD). The company set out to drive down the relatively high inventory days to a specified number of days.

Brandix, a front runner in Sri Lanka, has initiated many improvement projects in its various factories. Brandix Casualwear (BCW) one among many Brandix garment units, manufacturer of woven bottoms, basic pants, cargo pants, jeans, and shorts was the first company to be chosen to reduce the fabric holding time from fabric in-house to Planned Cut Date (PCD). The company set out to drive down the relatively high inventory days to a specified number of days.

Define Stage

The initial stage calls for narrowing down the project scope, which in this case was reducing fabric holding time for fabric in-house to PCD at BCW and the problem was finally defined as “In October 2008, it was learned that fabric holding time from raising of the Goods Received Notes (GRN) to PCD at BCW was on an average quite high as opposed to the standard entitlement.”

Measure Stage

After identifying and properly defining the problem, the fabric holding time from fabric in-house date to PCD had to be measured. Every week a report was generated to measure the fabric holding time from goods in-house to PCD. Afterwards, an average fabric holding time was calculated at BCW. This average was then identified as a baseline for the fabric holding time. Also at the measure stage a detailed process map, an input/output diagramme was made and an FMEA (Failure Mode Effect Analysis) was carried out for the process of fabric in-house to PCD.

Analyse Stage

This stage calls for analysing the report through a pivot table to figure out the time between fabric getting in-house and PCD by customer/by supplier/by merchant who raises the Fabric Booking Sheet (FBS) to get the fabric in-house from the mill. Upon analyzing the report, all the fabric that was not in-house within the target date prior to the PCD was highlighted and the reasons for taking longer were identified by the BCW Procurement team. The identified reasons were evaluated further to figure out the main root cause behind the high fabric holding time. Once the main root cause was identified through an ‘affinity’ diagramme, the process was further drilled down to find out the most minute level root cause behind this relatively high fabric holding time.

Improve Stage

Under this stage various action steps were collectively followed to drive down the fabric holding time from the current average. One improvement step that was followed was to make the marketing merchant responsible for driving down the fabric holding days, as it is up to the merchant to negotiate the terms for the fabric in-house date with the mill. Moreover a process map was drawn for the processes after fabric got in-house till the PCD and all the non-value added activities were identified so that fabric holding days/time could be reduced by eliminating these activities.

Mapping Stage

This stage requires mapping of all processes right from raising the FBS to getting fabric in-house from the fabric mill.

According to the process map the most critical non-value added activity was the large number of phone calls made to the fabric merchant by the marketing merchant at BCW to get the confirmation on date of delivery of fabric from the mill.

Control Stage

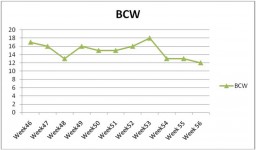

Sustaining the improvements is critical. Control charts were used to ensure that fabric holding days was kept within the target number of days.

The control chart below plots the fabric holding days over the time for Brandix Casualwear. It is evident that the holding days have been reduced considerably from fabric in-house to PCD over the corresponding weeks since the start of the project which was October 2008 and using Six Sigma Methodology.

The most important control is the report looking two weeks ahead which is generated to analyze processes between fabric in-house date to PCD by procurement merchant or by customer or by fabric supplier. Once the report is generated, all fabric lots for which the in-house date to PCD are more than the entitled number of days are identified merchant-wise and sent across to the merchant to take actions to reduce high fabric holding days, because fabric deliveries in the report are yet to happen. This report is generated fortnightly to analyze the fabric deliveries over the coming two weeks so that we have the possibility of reducing fabric holding days that are higher than the stipulated time.

The second control is putting in a procedure where Brandix Textiles sends BCW a delivery schedule of fabric 24 hours ahead of the actual delivery date so that BCW knows the deliveries that would come on time and the ones that are not going to come on time. Therefore, BCW can now fix the PCD for the deliveries that are coming on time so that fabric in-house to PCD can be driven down to the targeted days.

Project Savings

Six Sigma methodologies and the unwavering support of the BCW team, have managed to render Brandix Casualwear cash flow savings and savings to the Strategic Business Unit (SBU) bottom line on saving interest cost.

So far we have been able to save 7% of the monthly average value of fabric stock held from fabric in-house to PCD each month since November 2008, by reducing the monthly average fabric holding days against the base line.

Way Forward on the Project

Now that the fabric holding time at BCW has been considerably reduced, we are still working on how to reduce it further to our ultimate goal. Once our ultimate objective of reducing the fabric holding time is achieved, we will internalize the process improvement effort into the fabric procurement team to sustain the new fabric holding time going forward. After the complete hands-off of the project to the process owner, we have planned to move into Brandix Intimate Apparel (BIA) and roll out the best practices adopted in reducing fabric holding time at BCW to BIA.