The fashion industry is in the midst of a profound transformation. Technological innovations are reshaping every facet of our business, from production and supply chains to customer engagement and retail experiences. As we stand at this intersection of tradition and technology, it’s crucial to understand how these advancements can help us scale profitability and streamline processes without losing the artistry and craftsmanship that define our brands.

At Sartoria Vienna and the shirt dandy, premium menswear brands specialising in made-to-measure tailoring, we are embracing the opportunities technology offers while staying true to the values of quality and personalisation. In this article, I’ll explore how three key technologies – 3D configurators, mobile body scanning and pattern automation – are revolutionising not only our business but also the fashion industry at large.

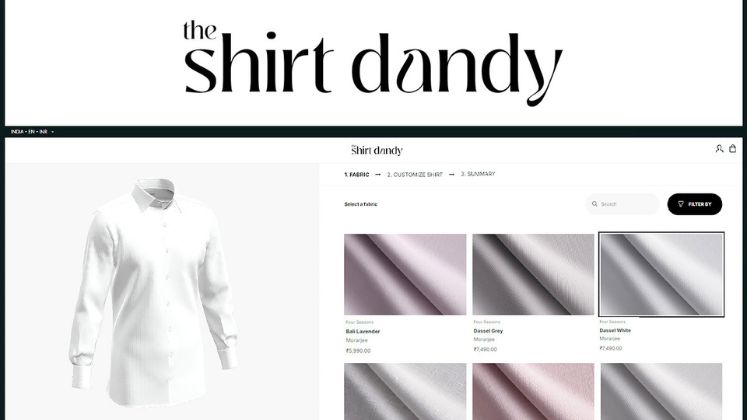

3D configurators: Enhancing customer engagement and personalisation

Customisation has always been the hallmark of high-end fashion, especially in the bespoke clothing market. Traditionally, this process required time-consuming consultations and repeated fittings to ensure the perfect garment. However, 3D configurators are transforming the customisation experience.

We utilise an advanced 3D configurator that allows clients to design their garments online in real-time. Customers can select fabrics, choose specific cuts and visualise their final product before a single stitch is made. This technology enhances customer engagement, allowing them to co-create their garments with ease, all from the comfort of their homes.

The benefit for us as a business is twofold: we can capture the client’s vision with fewer touchpoints, reducing the chance of miscommunication and simultaneously streamline our ordering process, as the client’s preferences are directly integrated into our production system. This not only shortens the sales cycle but also leads to higher customer satisfaction, driving repeat business and referrals.

Mobile 3D body scanning: Precision fit anywhere

One of the greatest challenges in custom tailoring has always been to achieve the perfect fit. Traditionally, this involved detailed hand measurements and multiple in-person fittings. However, the development of mobile 3D body scanning technology has been a game changer, particularly in tailoring.

Mobile 3D body scanning allows customers to use their smartphones to capture precise body measurements in minutes. We are going to implement this technology shortly to enable remote fittings, allowing clients from across the globe to experience the perfect fit without even stepping into our shops.

This technology has the potential to expand our customer base, breaking down geographical barriers and creating a seamless, tech-driven customer experience. Moreover, the precision of these scans reduces the margin of error, resulting in fewer adjustments and faster delivery times, which boosts overall profitability by cutting costs associated with alterations and remakes.

Pattern automation: Accelerating production while maintaining quality

While customisation has always been at the core of bespoke fashion, it historically required a labour-intensive, time-consuming process for pattern creation. Each new garment involved hours of manual work to create the perfect fit for a client. With the advent of pattern automation technology, however, we are able to streamline this process significantly.

Ultimately, pattern automation software can be used to translate a customer’s unique measurements from 3D body scans directly into a digital pattern, which are then optimised for production. This not only saves time but ensures that every pattern is precisely aligned with the customer’s dimensions, leading to a consistent and accurate fit every time.

Beyond this, pattern automation reduces material waste by optimising fabric usage. In an industry where sustainability is increasingly important, this efficiency in production contributes to reducing our environmental impact, while also lowering costs.

Case study: Integration of tech-driven solutions at the shirt dandy

Let me illustrate the impact of these technologies through a practical example in India with a client who is unable to visit our shop or meet our travelling tailor due to travel restrictions. Using mobile 3D body scanning technology, we could capture his measurements remotely, and through the 3D configurator, he is able to design his custom suit with our team virtually.

Once his measurements are processed, pattern automation software generates a digital pattern in a matter of minutes and the suit is completed within 7-14 days. The precision of the 3D scanning ensures a near-perfect fit on the first try, requiring minimal adjustments.

The entire process, from design to delivery, takes just two weeks, compared to the traditional four to six weeks required for a custom suit. By streamlining this process with technology, we not only increase customer satisfaction but also optimise our resources and labour, improving profitability and reducing lead times.

The future of fashion: Embracing technology for sustainable growth

As the fashion industry continues to evolve, embracing technology is no longer an option but a necessity. The integration of 3D configurators, mobile body scanning and pattern automation is just the beginning of a broader shift toward digitisation and efficiency in luxury fashion.

For brands like Sartoria Vienna and the shirt dandy, these advancements will allow us to scale our operations without compromising on quality or craftsmanship. By adopting tech-driven solutions, we’re not only improving profitability but also providing a superior customer experience, all the while reducing our environmental footprint.

The future of fashion lies in this seamless blend of tradition and innovation, where the artistry of bespoke tailoring meets the efficiency of modern technology. For those willing to embrace this change, the rewards – both for businesses and consumers – are vast.

| Thomas Hebenstreit (30), an Austrian finance professional, is the Founder and CEO of two innovative fashion brands. He launched the shirt dandy, introducing India’s first AI-powered 3D configurator for custom menswear and recently founded Sartoria Vienna, a luxury bespoke menswear brand featuring premium Italian fabrics, with garments made in the EU. Thomas has lived, worked and studied in Austria, Germany, Luxembourg, France and India and aims to redefine how men experience fashion. |