Sneaker production has been heavily dependent on petroleum-based synthetic materials such as rubber, polyester and EVA foams prized for their durability, flexibility and cost-efficiency. But, as sustainability becomes a key area of concern across the fashion and footwear industries, this model is undergoing a massive transformation.

Fuelled by long-term environmental impact and evolving consumer expectations, brands are now actively investing in natural and low-impact alternatives such as hemp yarns, bio-based rubbers and compostable or recyclable plastics. These materials offer a promising departure from fossil fuel-derived components by not only reducing dependency on non-renewable resources but also encouraging more circular production models. At the same time, these innovations are partially equipped to comply with existing production systems, particularly bio-based rubbers that can be processed in a way similar to synthetic ones. This allows brands to adopt more responsible materials without overhauling their entire manufacturing infrastructure, making sustainability a more accessible and scalable goal.

While still emerging, this shift signals a broader realignment of what a sneaker can be right from the raw material stage to its environmental footprint.

The future of sneaker production will increasingly depend on such material innovation, moving from extraction to regeneration and from waste to value.

| From an environmental perspective, sneakers crafted with alternative materials can reduce environmental impact by up to one-third compared to conventional pairs. |

Promise and Pitfalls of Sustainable Sneaker Production

From an environmental perspective, sneakers crafted with alternative materials can reduce environmental impact by up to one-third compared to conventional pairs. This is a meaningful improvement, especially in an industry where scale defines every decision, however, the long-term effectiveness of these solutions requires a re-evaluation of the entire product lifecycle.

-

Material Limitations and Longevity

One of the primary challenges heeded by brands in the space are in terms of durability. The majority of natural or bio-based alternatives lack the mechanical strength and wear resistance of traditional synthetics, resulting in a shorter lifespan of the product. If a sneaker needs to be replaced more frequently, the overall footprint remains substantial even if each pair is marginally ‘greener’.

-

Beyond Materials: The Case for Longevity and Repair

True sustainability extends beyond material swaps and brands and designers can heighten the impact of sustainable materials by improving the lifespan of sneakers by incorporating better construction, thoughtful design and offering after-care and repair services.

Unfortunately, most brands do not offer repair options, despite a growing number of consumers open to getting their products repaired and using them for longer rather than discarding them.

A business model that values longevity as much as low-impact sourcing will ultimately do more to reshape sneaker culture and reduce waste.

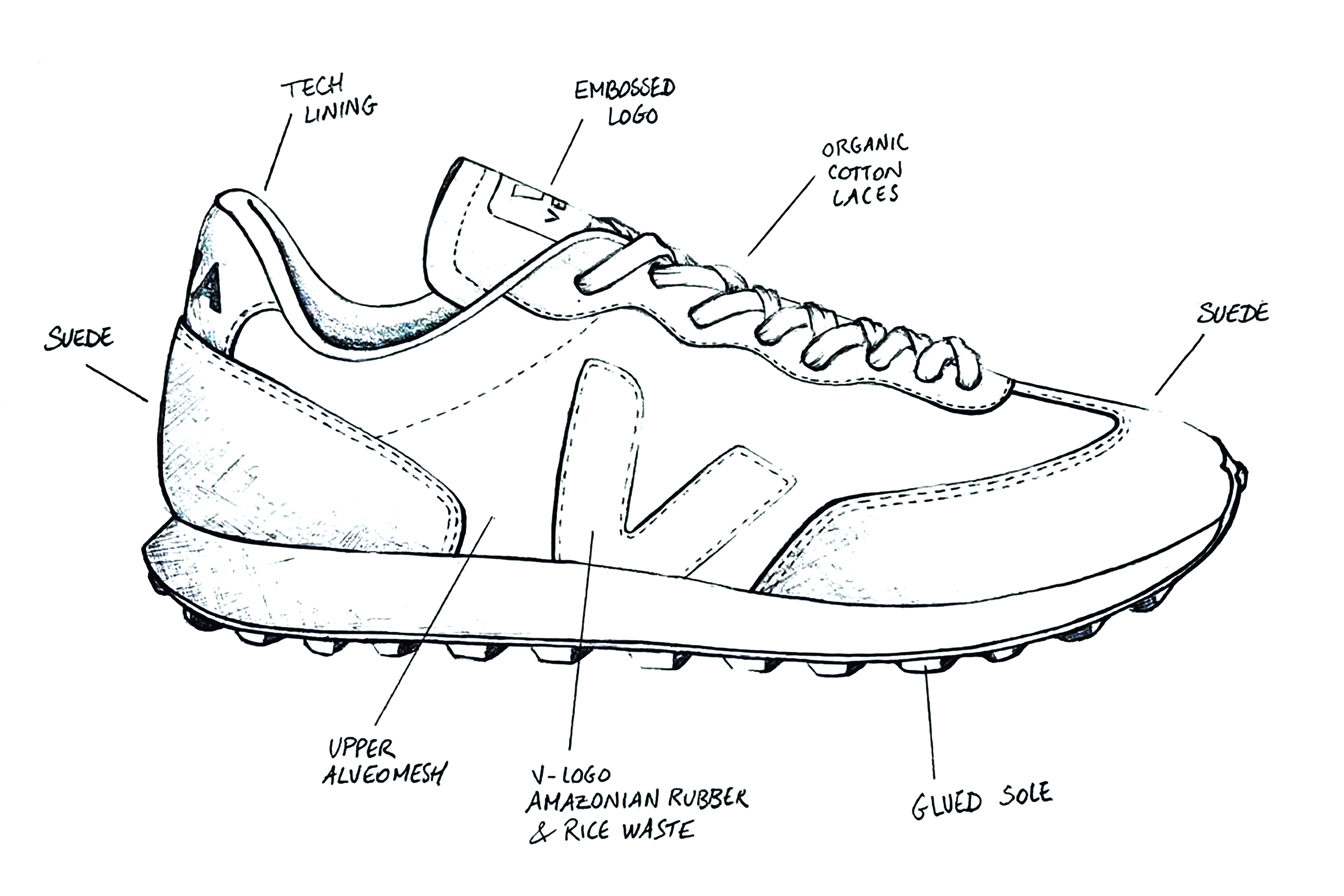

Case in point being VEJA, a brand known for its eco-conscious approach to footwear, launching its ‘Clean, Repair, Collect’ initiative to extend the lifespan of sneakers and promote sustainable practices within the fashion industry. In 2020, VEJA introduced cobbler stations worldwide, located in cities like Paris, Berlin and Brooklyn, where customers can get their footwear cleaned and repaired, reducing waste and championing a circular economy model.

Consumer Desire for Newness

In today’s fast evolving fashion landscape, consumers crave for novelty and self-expression. The growing interest in sustainability has led to a shift in mindset, where ‘old and repaired’ no longer means outdated or undesirable. There is a rising appreciation for mending, patchwork aesthetics and garments that tell a story.

By including repaired or repurposed garments into runway shows and lookbooks where patched fabrics, frayed edges and custom fixes are viewed as design features rather than flaws, brands and labels can help reframe wear and repair as a form of luxury craftsmanship.

For the sneaker category, this can be communicated via distressed finishes, visible sole patches, replaceable components or even limited-edition ‘repaired’ styles.

| Sustainable materials are a vital first step, but making durability, repairability and circularity equally crucial is where real progress lies. |

Pricing Challenges of Sustainable Sneakers

One of the key issues to scaling sustainable sneaker production lies in cost. Natural and bio-based materials such as hemp, cork or plant-based rubbers cost more than conventional synthetics, mainly because of a lack of economies of scale and the kind of sourcing required. Many of these materials are produced by niche suppliers, most of them located in regions such as Italy’s Marche district or Southeast Asia, where manufacturing operates at a smaller and more artisanal scale. These producers are not engaged in the same high-volume price competition as mainstream synthetic suppliers, resulting in raw material costs that are higher than average.

Despite their elevated price tags, the materials that go into creating a sneaker typically account for only around 20% of the final retail price, suggesting that higher sourcing costs are not the sole factor fuelling the price of sustainable footwear.

The real pricing challenge actually lies in production, limited batch runs and the branding required to position sustainability as a value proposition. As more brands begin to adopt and invest in these materials, there is a potential for economies of scale to reduce costs over time. But in the meantime, brands can make sustainable options more accessible by finding a balance between ethical sourcing, efficient production and strong storytelling that justifies the price and ultimately drives demand of the product.

Economies of Scale

While you see claims of sustainability increasingly becoming a part of brand narratives, their execution in the sneaker category remains limited. Many fashion players introduce sustainability through isolated capsule collections or a single ‘green’ model which is more of a symbolic gesture than a systemic shift, limiting the possibility of achieving economies of scale, which are crucial for lowering production costs and making sustainable options competitively priced.

To unlock true economies of scale, brands need to apply sustainable practices across core lines by treating eco-friendly materials and circular design as standard components of the product development cycle and not a niche proposition. When brands work towards achieving higher volumes and longer-term sourcing partnerships, they can help drive demand that will directly impact suppliers to lower their costs and build capacity.

| The momentum required for meaningful scale can be achieved when sustainability shifts from exception to expectation across an entire collection, resulting also in a more equitable price point for consumers. |

The Vision Gap in Sneaker Sustainability

Even though consumer demand and external pressure surrounding eco-conscious practices is growing, many companies still approach sustainability as a checkbox activity which reduces the potential of even well-intentioned initiatives.

Without clear set goals or a team committed to systemic change, brands are limited to surface-level solutions such as launching a single sustainable sneaker model or using partial recycled content without applying these practices into their overall business model.

Brands and designers can close this gap by fostering a sustainability-first mindset at all levels, right from executive leadership to design, sourcing and marketing. Building internal capabilities, investing in long-term roadmaps and empowering change agents within the company are no longer optional but are considered essential for remaining relevant in today’s retail climate.