Garment pre-production and merchandising functions are characterized by people in an organization doing multiple activities. While some of the activities are dependent and follow each other, a few others are independent, and hence run parallel to them. When both these activities are put together, it forms a chain of non-linear activities. The longest chain, in the thus formed network of multiple parallel activities, is called the critical path.

It is a common practice to use critical path logic in apparel pre-production activities, to timeline important activities with the ultimate goal to deliver order within the delivery date. The schedule of events, so formed is known as Time and Action (TNA) calendar. Not surprisingly all software catering to apparel pre-production planning have provisions to manage TNA or critical path management.

In the 1st part of the two-part series article, Prof. Prabir Jana from National Institute of Fashion Technology, Delhi, Prof. Alistair Knox from Nottingham Trent University, UK and Prof. A.S. Narag from Faculty of Management Studies, Delhi discuss and underline the existing problems and limitations of the current TNA making practices in the industry.

Despite claims of buying and manufacturing organizations, the processes of following up of orders/styles during the pre-production processes is flawed and the longer lead times and missed deliveries are still a common feature. The reason for such behaviour can be seen in the way activities are planned.

The largest transformation in the Apparel Industry is unfolding as a result of changes in trade regulation, disappearing quota systems and the dynamics between countries that have low cost labour, the raw materials and proximity to consumer markets”.

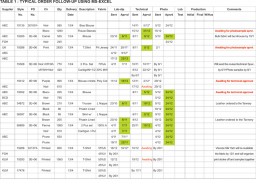

Majority of the organizations use MS-Excel to schedule activities against target date, which they call the TNA or critical path method. Quite often the buyer specifies target dates of key activities and based on those target dates TNAs are created by adding buffer days (to ensure that buyer target dates are not missed). It is also a common practice to prepare two TNAs; one with a few main important activities that were suggested by the buyer, while the other one with more number of in-between activities (to keep tab on in-house activities in micro details) and pre-poned target dates (to accommodate buffer time).

For example, TNA suggested by buyer may have only 4 target dates, i.e. fit sample approval date, size set approval date, lab dip approval date and planned cut date (PCD). While a TNA created by a manufacturing organization (for same order) may have target dates for total 15-20 activities: like pattern approval, grading approval, dispatch dates for all approvals, loading for bulk dyeing, receipt of fabric and accessories, etc.

Therefore, it is common that critical path of one order had 50-60 activities interlinked with each other in a complex network of activities thereby forming a PERT (Programme Evaluation and Review Technique) network and only 5-6 executives manage on average 8-10 such orders at a time. So at a given point of time one executive had to follow up average 64-80 discreet activities belonging to 8-10 different PERT networks.

To meet the needs of the plan executives generally maintain a “to do” list in his/her diary and attend whenever any activity misses the due date/time. Sometimes, unwittingly resources tend to migrate between several projects and hence to a “multi-tasking” in response to the customer demand in an attempt to keep as many customers satisfied as possible (Goldratt 1997).

There is no consensus or standard regarding whether TNA should be prepared for individual orders or group of orders. Often orders are placed in multiple colours, and each colour is having a specific order number. A style as a whole can get approval for fit sample and size set but for lab dips approval each colour has to be separately approved. Some buyers actually ask for such discrete colourwise lab dips, while others don’t. For a manufacturer working with different buyers, these lead to TNA follow-up being incomplete and erratic and non-effective.

Limitations of Commonly Used Spreadsheet Software

Limitations of Commonly Used Spreadsheet Software

The network diagrammes for individual orders have to be manually prepared in MS-Excel. This is time consuming and prone to error. Also, as a regular phenomenon during the course of progress of orders often activity sequences require to change. Incorporating such last minute manual changes in a spreadsheet software can be very cumbersome. Due to change of duration or change of sequence the critical path may change, MS-Excel can’t automatically incorporate such changes. Thus, it is the need of the hour to use specialized software for critical chain implementation.

Logical Flaws in Current Practices

While making network (PERT) of dependent activities we generally assign the time duration in days or hours but surprisingly never in man-days or man-hours! As there are only 5-6 executives who are expected to carry out 50-60 activities of any order, there will always be practical constraint of the availability of these executives, resulting in many of the parallel operations becoming sequential if the same executive is carrying out both. This phenomenon is overlooked while making TNA but it can constrain the actual execution and can result in delaying of the activities.

| Serial | Order No. | Activities | Activity type |

| 1 | AT009 | Making patterns for fit sample | Critical |

| 2 | AT013 | Grading patterns for size set sample | Non-critical |

| 3 | AT0021 | Making patterns for fit sample | Critical |

| 4 | BZ0013 | Making production pattern from size set comment | Non-critical |

| 5 | BZ0015 | Grading patterns for size set sample | Non-critical |

Another major problem that usually arises is wrong prioritization. On any given day there may be different activities from different styles/order (and hence from different TNAs) waiting to be executed. As no combined prioritization of activities was possible, everyone sets their own priority leading to conflicting order of activities. Executives move between tasks leaving them half-finished… resulting in poor efficiency.

Generally better organized executives are known for their foolproof follow-ups.

| Serial | Order No. | Activities | Activity type |

| 1 | BZ0013 | Making production sample | Non-critical |

| 2 | BZ0015 | Making size set sample | Non-critical |

| 3 | LZ003 | Fit sample making | Critical |

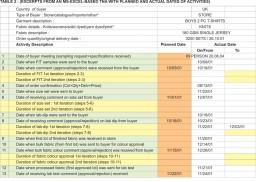

To-do lists of activities are maintained in diaries, and hand phone schedulers to ensure timely reminders and no goof up in following up of activities. The TNA software also print daily to-do lists for every executive, but no one realizes that these to-do lists in isolation offers no synchronization between the working of two executives, which is of utmost importance. For example, the system generates a to-do list for patternmaker and sample master like below.

While the executive Chandar Kumar knows that he has to complete the 5 activities on 12th September, but he does not know at what sequence. As a matter of fact anyone would start with the activity listed first, so Chandar Kumar starts with AT009, i.e. making patterns for fit sample. Similarly, Surinder Singh would like to follow his to-do list as per serial number, in the above case scenario to make production sample, but he will not be able to do so as production patterns are not yet prepared by predecessor (which is listed as 4th activity in Chandar Kumar’s list). Ideally there has to be synchronization of priorities between executives for a set of orders that they follow.

While the executive Chandar Kumar knows that he has to complete the 5 activities on 12th September, but he does not know at what sequence. As a matter of fact anyone would start with the activity listed first, so Chandar Kumar starts with AT009, i.e. making patterns for fit sample. Similarly, Surinder Singh would like to follow his to-do list as per serial number, in the above case scenario to make production sample, but he will not be able to do so as production patterns are not yet prepared by predecessor (which is listed as 4th activity in Chandar Kumar’s list). Ideally there has to be synchronization of priorities between executives for a set of orders that they follow.

Instead there will be complete chaos, as to-do list were prepared by picking up dates of specific activities from separate TNAs of AT and BZ (see order no. in the table) in isolation, following mere alphanumerical sequence by computer and not according to any combined TNA. Interestingly the idea of combining multiple TNA into one and then following only one integrated TNA was never thought by any merchandising executives.

Conclusion

Practically the scenario is more complex than being thought, network for any order has 50-60 activities on average, 8-10 orders are being looked after by 5-6 executives. Combining 8-10 such networks will have numerous permutations and combinations, follow complex algorithms and not possible either using pen and paper or using MS-Excel.

While Critical Path Method is more appropriate for machine-driven activities, a little improvised concept called Critical Chain (Goldratt 1997) addresses the human controlled activities better by incorporating both human side and algorithmic methodology side in a unified principle. In the next part we will see how the current approach can be overcome by following multi-order TNA approach applying critical chain principles.

Parallel Planning for Multiple Orders

Parallel Planning for Multiple Orders

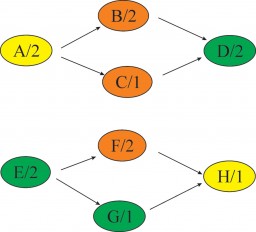

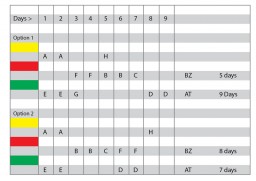

One example will explain the complexity of multiple orders being handled by common executives. One company Parabola Enterprises is working with AT and BZ buyers. AT has given TNA with four activities (A,B,C,D) to meet the due date, similarly BZ has also given their TNA with four activities (E,F,G,H). Only three executives – yellow, orange and green – take care of all activities and the dependency of the activities are shown in the diagramme. We can see yellow executive carries out A activity of AT as well H activity of BZ, while A activity takes 2 man-days to complete, H activity takes only one day. According to TNA of AT the critical path is 6 days (A-B-D) and critical path of BZ is 5 days (E-F-H).

As per common practice the organization promises to AT that final activity D will be completed in 6 days and also promises to BZ that their final activity H will be completed in 5 days without realizing the constraint on resources. The promises can be met if there is no sharing of resources and there are different executives for different activities and also for different buyers.

As per common practice the organization promises to AT that final activity D will be completed in 6 days and also promises to BZ that their final activity H will be completed in 5 days without realizing the constraint on resources. The promises can be met if there is no sharing of resources and there are different executives for different activities and also for different buyers.

In TNA of AT B and C is parallel activity but incidentally same executive orange has to execute both. So, practically the critical path will be A-B-C-D and consume 7 days instead of 6 days. This is a very common but serious problem in current practices of merchandising, due to which TNA follow up is often erratic.

In reality how exactly the executives work? The yellow executive start A activity of AT and simultaneously green executive starts with E activity of BZ. But the orange executive can either start with B or F activity. When F is done first then BZ due date can be met in 5 days but AT is being delayed to 9 days. If B is done first then AT can be delivered in 7 days but BZ is delayed to 8 days. It is very clear from the example that there can be various options by changing the sequence of activities.

In reality how exactly the executives work? The yellow executive start A activity of AT and simultaneously green executive starts with E activity of BZ. But the orange executive can either start with B or F activity. When F is done first then BZ due date can be met in 5 days but AT is being delayed to 9 days. If B is done first then AT can be delivered in 7 days but BZ is delayed to 8 days. It is very clear from the example that there can be various options by changing the sequence of activities.

So, when any organization follows up multiple orders it is not enough to treat individual TNA in isolation, rather a multi-order TNA would be the answer. A possible multi-order TNA network for the above AT and BZ example would look like below