Developing quick (style) changeover capability is paramount for successful implementation of lean, flexible or small batch manufacturing system. It has become even more important for apparel manufacturers catering to high fashion garments, which are characterized by small order quantities and shorter lead times. Though a quick changeover tool like Single Minute Exchange of Die (SMED) is extensively practiced in automobile and other process industries, its application in apparel industry has been limited to few manufacturers having access to technical knowhow. In contrast to general perception that SMED being a highly sophisticated process, demands highly trained manpower, Chandrark Karekatti, an industry consultant, based on his experience in lean implementation, has found this tool to be very simple and easy to implement even with the existing shop floor manpower. The article attempts to demystify the SMED implementation process in needle industry and help develop quick changeover capability.

To understand SMED implementation, it is essential to understand different phases of changeover processes. Firstly, it is important to understand that the phrase “single minute” does not mean that all changeovers and startups should take only one minute, but that they should take less than 10 minutes (in other words, “single digit minute”). Secondly, a ‘changeover’ is the complete process of change that takes place between the manufacturer of one style to the manufacturer of an alternative style to the point of meeting specified production and quality parameters.

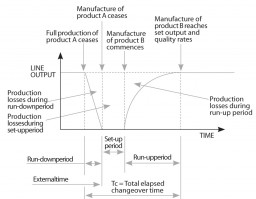

Distinguishing the phases of changeovers (Figure 1)

1The total time elapsed in changeover consists of three phases – the run-down phase; the set-up phase; and the run-up phase.

Run-down phase: This phase is the interval when production of old style is complete but set-up for new style cannot be started

as some of the pieces of old product are still in line for alterations or waiting for some parts or trims, for example a damaged placket, a missing collar, etc. In this phase feeding is ceased and production of old style is finished on most of the work stations. Run down typically stretches till all the pieces of old style are out from the line.

Set-up phase: It is the phase in which no manufacturing occurs. In this phase, machines and equipments are adjusted as per the requirements of new style. In this phase there is no output from the line.

Run-up phase: This phase starts when production for the new style is commenced and continues until consistent output at full capacity occurs. Run-up period extends till each operation (including new operations) reaches the specified production and quality rates consistently.

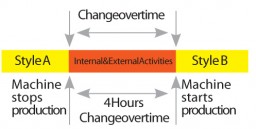

Internal and External activities in Changeover process (Figure 2)

Close analysis of changeover process reveals that the process comprises of two sets of activities, namely the internal activities and the external activities.

The internal activities are performed when the sewing machines in the line are stopped, and no product is being manufactured in the line. These are activities performed for sewing machines that are already in line, example gauge set, SPI change, folder adjustment or any other similar operation, as per the requirement of new style. The time taken to complete all the internal activities constitutes the set-up phase.

The external activities are performed outside the line without disturbing the production inline. For example, pre-setting of a sewing machine for new style or early loading of cut parts without disturbing the production of running style.

While the internal activities need to be carried out in the set-up phase when the machine is stopped. The external activities can be carried out during run-down phase and/or during the run-up phase.

Implementing Single Minute Exchange of Die (Figure 3)

Quick changeover is not an isolated process, where specially trained work force carries out the changeover activities. It requires focus on Organizational improvement and design improvement. Following are the six techniques that should be considered while implementing SMED:

1. Segregate or set apart the internal from external set-up operations (tasks)

2. Convert internal to external set-up tasks

3. Standardize functions

4. Adopt parallel operations

5. Improve design of machine equipments

6. Use functional clamps or eliminate fasteners and adjustments.

While steps 1 to 4 focus on organizational improvements, steps 5 and 6 focuses on design improvement.

It is quite evident that limited scope of design improvement makes SMED implementation in apparel industry to rely mainly on organizational improvement.

Organizational Improvement needed

Since developing quick style changeover capability needs cultural change, initiating organizational changes becomes essential. And since the organizational changes are basically people and procedure based, it mainly deals with manpower allocation/reallocation and task modification but not with equipment or product, which is dealt in design improvement. Organizational improvement is highly dependent on training and motivation. Following are few examples for initiating organizational improvement in apparel industry:

• Identifying Internal and External Activities: Machine plan should be prepared by comparing operation bulletin of old and new style. Machine plan should identify following parameters

(Refer Exhibit 1):

1. Operation type

2. Machine type (segregated as internal/external)

3. Machine number

4. Stitches per inch (SPI)

5. Required Settings.

Operations of old style and new style should be compared for segregation of internal

and external elements. If operation for new style is already being performed in old style then the element is internal, thus the machine type should be filled as internal element. But if a machine has to be arranged from outside or a machine from the old style will become idle but can be utilized at some other operation in the new style, then that should also be filled as external element. Along with machine type attachment details should also be filled by referring to operation bulletin.

• Convert Internal Task to External: Since reallocating task by converting internal activities to external activities significantly reduces set-up time, opportunities for such conversions should be identified. Example, loading of parts before the end of old style or template preparation in advance.

• Investigate the use of Automates/Work Stations: Like continuous bottom hemming machine for knits Tee/Polo shirts (internal to external elements) or the use of fusing machine in cutting section rather than in sewing line.

• External Machine Setting: External machines should be set-up by the mechanic according to the machine plan in advance (in run-down phase). Typically machine setting should include machine parameters like gauge change, folder/presser foot change, needle change/removal, SPI adjustment, programming, etc. as per the requirement of new style. Machine setting should be approved for quality by the quality supervisor and machine marked with ‘Setting OK’ tag.

• Adopt Parallel Operations: Set-up parallel operations example, set-up of operations in different sections simultaneously (front and back sections). Note that the tasks must not be dependent upon each other. Usually, the creation of parallel tasks requires more manpower, so increased personnel must be considered.

• Eliminate Waiting Time: Concentrate on efforts to eliminate waiting time during changeover process. A simple reallocation or reorganization of group tasks may help reduce this waiting time. For example, performing bottom hem operation before waistband attach in a denim for starting few bundles, as set-up of waistband operation consumes more time.

• Training and Development: Traditional changeover procedure can be modified by broadening the scope of a technician’s abilities through training programs. This will allow a technician to perform tasks that he or she was not previously allowed to do – and thus remove dependency on another technician for completion of a task.

• Minimize Trials and Controls: Trials and controls can be minimized by formalizing procedures and utilizing standards. Checklists can be used, and technicians can be held accountable for key procedures by signing off on the checklists.

• Standardize Functions: Formalize standardized operation instructions for changeover process. Examples develop standard operating procedures defining responsibility and accountability.

Design Improvement

Following are few examples of design improvement in apparel industry:

Improve Design of Manufacturing Machine and Equipment: Investigate use of clamps instead of fasteners wherever feasible, for example use magnetic edge guides in place of screw fastener type.

Improve Design of Manufactured Products: Exercise the scope of changes in product construction parameters in consultation with buyer to facilitate reduction in set-up time. For example, margin for strip matching at sleeve joint for yard dyed knits, increasing/ decreasing SPI by a unit as the specified SPI cannot be produced on some machines or to increase the width of J Stitch so that it can be easily performed on J Stitch machine. However since such changes require buyers consent, which often is a time-consuming process, they have limited application.

It is observed that in comparison to design improvement, organizational improvement is cheaper, easy to implement, and produces significant reductions in changeover time.

Administer Functional Controls

While implementing SMED, it should be guarded that the saving in changeover time is not negated by poor functional controls like, non availability or shortage of fabric/trims after commencing production, non adherence to PPM schedules, poor style clarity among production supervisors and many more such small irritants but with a major implication.

Exhibit 1 shows the machine plan for style No. 6679B-cargo shorts, identifying segregation of internal and external activities. Column 2 represents all the operations in new style captured from operation bulletin, while each operation is identified as internal or external operation. Column 3 represents attachment details captured from operation bulletin and column 4 represents machine allocated for that operation. For external elements, machine numbers should be allocated in consultation with maintenance team. While column 5 represents stitches per inch details captured from tech pack, column 6 represents machine settings details filled by comparing the operation bulletins of new and old styles.