It is rarely seen in India that a Senior Minister from Central Government not only appreciates the potential and model of an apparel manufacturing hub but even insists to replicate the hub’s model across India. Recently Union Commerce & Industry and Textile Minister Piyush Goyal said that the Government wants to create 75 textile hubs like Tirupur which will not only support textile product exports and ensure the inclusion of sustainable technology but also create massive employment opportunities. And the Minister is quite right as 35 years ago, this hub was exporting Rs. 15 crore worth of textile products which is today more than Rs. 30,000 crore, a growth of two thousand times!

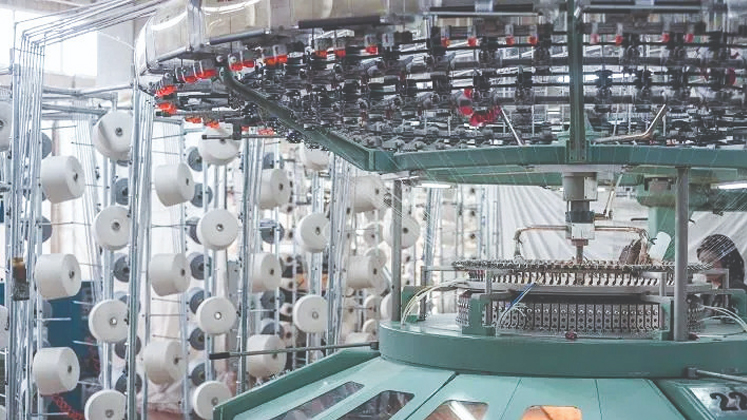

While visiting Tirupur, at first sight, the city seems like any other city in India but when one digs deep into its apparel industry, there are many such things which are not so common in other Indian apparel manufacturing hubs. It is the combination of strong infrastructure, local entrepreneurs’ skills, local business leaders and supportive State Government policies that over the years have helped build a strong ecosystem and ensured the consistent growth of Tirupur.

This hub could be sighted as a right example of how a small village around four decades back has now become India’s top knitwear export hub. The factors discussed below confirm how Tirupur has become a successful apparel manufacturing hub and what are its exclusive benefits that make it a preferred choice over other apparel manufacturing hubs.

Importance of Tirupur in India’s garment manufacturing landscape

As per Tirupur Exporters’ Association (TEA), Tirupur garment exports clocked Rs. 33,525 crore in 2021-2022 (US $ 4.51 billion) which is 1.07 per cent of all India merchandise exports in 2021-22. From India’s export of knitwear-based apparel products, Tirupur alone has more than 50 per cent share. The hub also has a good share in Indian domestic market as the data available with trade bodies shows that it had a turnover of Rs. 50,000 crore (both exports and domestic) in 2019-20.

Tirupur’ apparel industry comprises 95 per cent of MSMEs. Overall nearly 9,000 units employ around 6 lakh workers directly, and out of this, 65 per cent are semi-literate women from rural areas. Due to the presence of a strong apparel industry, indirect employment is over 4 lakh. Tirupur knitwear cluster exports share in total Tamil Nadu’s exports is 13.5 per cent.

Raja. M. Shanmugham, President, TEA strongly believes that as this hub has performed well despite all the challenges, and things remain in its favour, hence, Tirupur exports would certainly double its turnover in the next 2 to 3 years.

Entrepreneurial skills make it a go-to place for apparel business

The cluster’s driving mantra is ‘Yesterday’s Labour is Today’s Owner’ and some of the SME firms have transformed themselves from job work to export houses. They have grown gradually from micro to small, small to medium and medium to large. Local entrepreneurs have taken the right decision at the right time like many exporters of Tirupur are also exporting MMF-based products, and not just sticking to 100 per cent cotton. They have invested in the required technology and taken the calculated risk as and when required. The majority of exporters keep investing money in their core businesses which has helped them in continuous growth. Focusing on basic knitted products to high value-added products and continuous improvement across all levels are core strengths of Tirupur’s entrepreneurs.

Efforts of Tirupur’s entrepreneurs are also praiseworthy as they started working and grew when the basic infrastructure was not strong in the hub.

“Unity in competition is a unique point of Tirupur’s entrepreneurs as we compete with each other while taking orders but also support each other in execution. As and when any entrepreneur needs any support from any other entrepreneur, they happily support each other,” says Raja.

Many companies in this hub are also known for their best practices and they have state-of-the-art plants with latest technology – Eastman Exports Global Clothing; AKR Textiles; SCM Garments; Best Corporation; KM Knitwear; SP Apparels; Cotton Blossom; Armstrong Knitting to mention a few. From cutting room solutions to hanger systems to 3D software, various companies have upgraded themselves from time to time.

The gen-next in Tirupur is also taking full interest in the business and the majority of the companies, be it small or big, have now young leadership also.

Strong local leadership is exemplary

Strong apparel industry leaders like A. Sakthivel (currently serving as Chairman of Federation of Indian Export Organizations [FIEO]), Raja M Shanmugham, current President of TEA are from Tirupur. Right from State level to Union Government and local administration, Tirupur’s local business leadership has delivered as per industry expectations.

Even the TEA has its own NIFT-TEA College of Knitwear Fashion (founded in 1997) which has become instrumental in the availability of mid-level professionals for Tirupur’s apparel industry. The association also has an equally strong focus on skill development of the operators working within the industry.

Due to strong local collective efforts in 2016, Rs. 200 crore was sanctioned by the Government for Tirupur dyeing industry for the 18 CETPs (Common Effluent Treatment Plants) as an interest-free loan to be converted into grant based on the performance of the CETPs. At that time, Tirupur was facing problems on account of its huge investments in the first-ever Zero Liquid Discharge (ZLD) projects in the country. And today the hub has nearly 300 dyeing units, and 60 processing units recycling almost 12 crore litres of water a day.

Collective efforts of Tirupur were also recently noticed while opposing the unprecedented hike in cotton and yarn price. The entire hub went on strike and kept the production on hold. There was no such similar example seen across India while the cotton price issue was an equal challenge for the apparel manufacturers in the country.

The apparel industry in Tirupur also is comparatively more open to collective efforts and believes in information sharing. This South Indian city is also known for its knowledge-sharing events.

Being the Founder President of TEA, A. Sakthivel’s immense contribution to the growth of Tirupur exports has outstandingly grown from a mere Rs. 15 crore to today where it is. Apart from various efforts to make Tirupur a leading apparel exporting hub, A. Sakthivel has been honoured with the Padma Shri award in 2009 also. He is also a prime mover of many visionary projects executed in Tirupur including Tirupur Export Knitwear Industrial Complex (TEKIC); Inland Container Depot (ICD); New Tirupur Area Development Corporation Limited (NTADCL); NIFT-TEA Institute; India Knit Fair Association (IKFA) and Netaji Apparel Park (NAP) to mention a few.

Similarly, Raja M Shanmugham was also nominated by the Director General of Foreign Trade (DGFT) as a non-official member for the board of trade, an important platform to work on export promotion. He is also a member in the State Export Promotion Committee.

It is not that there are only these two leaders who are active. Nearly all the segments of the textile and apparel industry have a strong association in Tirupur and their representatives are actively working to support the industry.

State Government’s continuous support

It will not be wrong to say that Tamil Nadu is amongst the top in Indian states when it comes to supporting the textile and apparel industry. Be it at policy level or other allied support, the state is having an edge on this front. For example, it boasts of the lucrative Tamil Nadu technical textiles policy with thrust on medical textiles and MSME policy.

A few of the recent steps show the consistent support of the State Government, like in the recent budget, it put a lot of focus on workers’ development be it skill development or ease of migratory workers and launched mobile information and help centres for migrant workers including Tirupur which will help to know their details and also reduce untoward incidence. The State Government has also announced cancellation of 1 per cent market cess on cotton and waste cotton. Not only this time and again, the CM of the state has also urged the Union Government to support the industry on high cotton price issue. Such aggressive support and actions are hardly seen in any other Indian state.

Strong overall infrastructure

Tirupur has comparatively a great infrastructure. For example, with 54 units, Netaji Apparel Park, spread across more than 150 acres, is one of the best apparel parks in India and it is contributing one-tenth of Tirupur’s apparel exports. It has all the facilities required to be a good apparel cluster be it uninterrupted power supply with 110/11 kV substation, neat and clean environment besides a massive solar plant of 3.4 mW.

Tirupur is almost 55 km from Coimbatore, another leading textile hub, having an airport with good connectivity across India. Road connectivity from Tirupur to Coimbatore is also comfortable and there is no reason why buyers won’t prefer to visit Tirupur. Overall basic infrastructure is also comparatively good in the city, especially compared to other apparel manufacturing hubs.

The nearest port, Tuticorin Port, is also around 333 km away from Tirupur and it takes around 7 hours for goods to reach from Tirupur to Tuticorin. Apart from this, there is Chennai Port, the second largest container port of India and Ennore Port, both of which are almost 500 km away from Tirupur.

TEA Lemuir Container Terminal, about 10 km from Tirupur, arranges for the loading and unloading of export and import cargo in Tirupur itself.

Local raw material availability is also a big strength of the hub. Cotton to yarn, fabric and a variety of trims, nearly all raw materials are easily available in Tirupur and nearby areas.

Nearby developed hubs helping to attract more buyers

Coimbatore (known for textile mills, yarn, home furnishing, garments and spinning machinery), Erode, Salem and Karur (known for powerloom and handloom fabric and home furnishing products) are the four major textile hubs near Tirupur and the development of these hubs has attracted overseas buyers and initiated a culture of textile business. Coimbatore alone has around 15 per cent of the textile mills of India.

Jointly these four hubs offer an entire range in knit-based, right from yarn, fabric to a variety of apparel and home furnishing. Many companies present in these hubs are vertically integrated, focusing on apparel as well as home products.

Tirupur, a unique self-made cluster, has envisaged a target of Rs. 1 lakh crore export by the year 2024. And with the spirit of Tirupur and overall condition, achieving this target is very much possible. Like many other hubs, Tirupur also has challenges and problems but the good thing is that Tirupur’s collective efforts are doing their best and the hub is moving ahead despite all odds. Every apparel manufacturing hub needs to develop like Tirupur.

| 6 lakh | Rs. 1 lakh crore | 9,000 |

| workers | export target by the year 2024 | units |

In India, normally clusters develop through two ways. The first is through the establishment of any public sector undertaking (PSU) that develops a supply chain also. Government plays a very crucial role in such clusters. The second way a hub is created is through the investment of any stalwart like Jamsetji Tata, Founder of Tata Group, who established Jamshedpur. Local strength be it any skill, craft or availability of particular material, are critical factors in the development of such hubs. Tirupur has developed organically in a separate way with the efforts of local entrepreneurs.