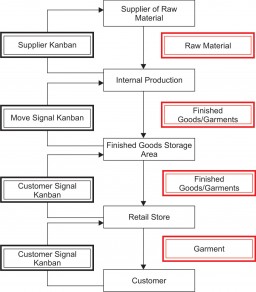

The Kanban System is a means of letting people – including the manufacturing operators, logistics personnel, helpers and truck drivers know what to do. It is an information system centered on an instrument of communication called Kanban. Anjana Seshan, a Final Year student in Undergraduate Program in Fashion Merchandising & Production (FMP) and V. G. Venkatesh, Associate Professor, FMP Program, Pearl Academy of Fashion, Chennai Campus, make a quick review of this system.

Kanban, meaning “visible record” in Japanese, is a system of notification from one process to the other in a manufacturing system. It is a system of continuous supply of components, parts and supplies, such that workers have what they need, where they need it and when they need it.

Kanban, a Japanese word, pronounced as kambaN, is made of two words kan means “visual” and ban means “card” or “board” – The term is synonymous to “Demand Scheduling” and “Just-In-Time (Manufacturing)”. The system helps the operators manufacture goods based on the actual usage rather than the forecasted usage.

The operators only produce new product to replace the product consumed by its consumer(s) or the immediate next process. Since the majority of the decisions in a Kanban are being made by the operators, the use of visual indicators also allows managers and supervisors to see the schedule status of a line at a glance. The Kanban schedule replaces the traditional daily or weekly production schedule. Kanban scheduling can be looked at, as an execution tool rather than a planning tool.

How the Kanban System Works

A card is the most widely used way of conveying information in a Kanban System. However, there are other signals like RFID tags, bar code signals, colour coded or dedicated containers. Basically, “the only true requirement is a clear, visible signal that indicates specific action”. These cards are circulated among the workers or operators from start to finish within each work station and then back to start again. The process gets repeated.

There are six important rules to observe when following the Kanban System:

- Downstream processes withdraw items from upstream processes,

- Upstream processes produce only what has been withdrawn,

- Only 100% defect-free products are sent to the next process,

- Level production must be established,

- Kanban always accompany the part themselves, and

- The number of Kanbans is decreased gradually over the time.

There are two most commonly followed Kanban systems today:

1. Withdrawal Kanban (Withdrawal Card)

2. Production Kanban (Production Card)

WITHDRAWAL KANBAN/ WITHDRAWAL CARD

The main function of a Withdrawal Kanban/Card is to pass the authorization for the movement of parts from one stage to another. Once it gets the parts from the preceding process and moves them to the next process, it remains with the parts until the last part has been consumed by the next process.

It then travels back to the preceding process to get parts, thus creating the cycle and conveys on when to move; what to move; where to move; and how much to move. Further it carries the part number, part name, lot size, routing process, and name of the next process location/container, name of the preceding process location/container; container capacity and the number of containers released.

PRODUCTION KANBAN/PRODUCTION CARD

The primary function of the Production Kanban is to release an order to the preceding stage to build the lot size indicated on the card. A production Kanban conveys different information: when to make; what to make (to be precise what the preceding process should make) and how much to make. Production Kanban card should have the following information: materials required as inputs at the preceding stage; parts required as inputs at the preceding stage; and information stated on withdrawal Kanban.

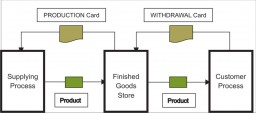

Example: The customer process, whether it is an internal or external customer, requires us to provide them with our product. T his signal to move the products to the customer are accomplished through a Withdrawal Kanban Card. Withdrawal simply means that we are transferring our product to the customer based on their request…

The function of the Withdrawal Kanban is to move product to the customer from the store. When product is removed from the store by the use of Withdrawal Kanban Card, the Production Kanban Card already in the container at the store, is sent back to the supplying process to tell them it is time to replace what has been moved to the customer. Without a Production Kanban, the supplying process cannot make material, which prevents the overproduction of parts. This is commonly seen in domestic retailers in India, like Pothys, Chennai Silks and Naidu Hall, where a new product is just produced to fill the empty space in shelf.

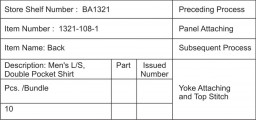

An example of filled Kanban Cards, for both Withdrawal Kanban and Production Kanban.

Withdrawal Kanban Card: Here the card specifies the kind and quantity of product that should be taken from the preceding workstation to undergo a manufacturing process. Consider, a men’s long sleeve, double pocket shirt, having three panels on the back, for which the preparatory process of back is going on. The first step would be attaching of the panels in the back and then the yoke will be attached. The sample card attached (see Figure. 1) is a withdrawal Kanban Card, where:

- ‘Store shelf number’ indicates where the finished product has to be placed; the code ‘BA’ means backs and 1321 is the style# / PO#.

- ‘Item number’ talks about the numbering of the specific item which includes the style# / PO# (1321), followed by the bundle number (108) and the piece number in the bundle (1).

- ‘Item name’ indicates the part on which the workstation should work.

- ‘Description’ shows the description of the garment.

Here the Kanban Card travels from the ‘Yoke attaching and top stitch operation to the panel attaching operation’. Only when the Kanban Card is shown, the parts are issued for manufacturing. Once the yoke attaching is done, the part will be placed on the shelf number: BA1321, from which the part is withdrawn for the next process.

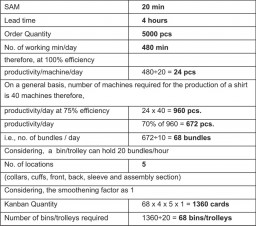

Kanban Development Calculation (see Table 1.)

- Kanban Quantity : This is the number of Kanban Cards that are required in the factory for repetitive use, for smooth and fair production.

- Weekly Part Usage : As the name implies, the number of parts (bundles) considered to finish in that week.

- Number of Locations : The number of locations where full containers are required to begin the production.

- Smoothing Factor : The smoothing factor is used to account for seasonal fluctuations in demand. It is constantly determined by the ratio of the fluctuating demand to the regular demand.

Consider a factory, producing basic men’s shirt at an efficiency of 70%, with Progressive Bundling System as the production system. In this case, Kanban quantity would be the number of bundles (pre-assuming that the no. of pcs./bundle is 10), of each part to be produced in a day. This is because every bundle would carry a Kanban Card (see Table 2).

BENEFITS OF KANBAN

1. The setup time of the factory is significantly reduced.

2. Allows the reduction or elimination of the inventory held to cover the change over time.

3. The flow of goods from warehouse to shelves is improved, leading to an increase in the productivity.

4. Employees having multi-skill are used more efficiently.

5. Better consistency of scheduling and consistency of employee work hours.

Companies such as Bannari Amman Apparels, Gokaldas Images and few others have started using the variations of visual control (Kanbans) in the production floor for getting better efficiency.

However, the biggest hurdle in the implementation of the Kanban might be the determination of employees to stick cards while withdrawing or starting production. However, with recent development of electronic Kanban systems or E-Kanban systems common problems such as manual entry errors and lost cards have been eliminated.

E-Kanban systems can be integrated into enterprise resource planning (ERP) systems. Integrating E-Kanban systems into ERP systems allows for real-time demand signalling across the supply chain and improved visibility. Data pulled from E-Kanban systems can be used to optimize inventory levels by better tracking supplier lead and replenishment times.

The aim of Kanban actually coincides with the actual aim of any production unit – reducing inventory and WIP. With the gradual reduction of number of Kanbans, the goal will ultimately be attained.