Providing a comfortable workplace is one of the basic requirements of every manufacturing organization. Amongst the biggest concerns for managers of large facilities are energy efficiency and growing energy costs that can make heating and cooling of a large space very expensive. According to an estimate, over half (64 per cent) of a facility’s total energy usage is from heating/cooling and lighting. Though garment manufacturing facilities in South-east Asia may not require much of heating, but energy cost is still a major concern for the factory owners. High Volume Low Speed (HVLS) fans – used alone or in tandem with Heating, Ventilation and Air-Conditioning (HVAC) systems – are an innovative yet affordable option for controlling costs without compromising on comfort at the workplace. Team StitchWorld takes a closer look at HVLS fans and its advantages…

While ducting-based air-cooling solutions are gaining ground, traditional ceiling fans are the most commonly used air-circulation solutions in the industry. There are factories which use air-blowers and air-exhausts on opposite walls of the shop floor for horizontal airflow. This however gained limited success as the airflow speed varies with distance covered, and extreme speed near the wall can be disruptive for several operations.

What is an HVLS fan?

HVLS fan is a large ceiling fan that moves high volume of air at a low speed. The low speed delivers gentle air movement rather than disruptive wind. Also, the circulation of a high volume of air, effectively distributes airflow over a large area. These fans create air curtains and non-disruptive airflow, thereby minimizing the need for expensive ductwork at the factory; and unlike the traditional ceiling fans, just one HVLS fan is capable of covering an area as large as 22,000 sq. feet and can replace as many as 10 to 20 floor fans, or smaller ceiling fans. HVLS fans, with diameter ranging from 8 feet to 24 feet; run at the maximum speed of 64 RPM; and comprise of dual functionality to work during both summer and winter with anodized fan blades to prevent them from corrosion, are very effective. The standard drop of mounting the HVLS fans is about 3 feet from the ceiling since these huge fans require ample space above them to transfer the air to ground and function properly.

How does it work?

As per a study at Waseda University in Tokyo, for every degree rise in temperature above 25°C, productivity drops by 2 per cent. HVLS fans serve as all-purpose industrial grade ventilators that can reduce such risks while improving the comfort of the facility users and also reducing the electricity bill.

HVLS fans work on the simple principle that “gently moving cool air breaks up the moisture-saturated boundary layer surrounding the body and accelerates evaporation to produce a cooling effect”. And hence, the HVLS fans take a different and smarter approach in the design as compared to a regular ceiling fan, where a standard fan is designed with smaller blades that spin faster to cool down an area.

These HVLS fans make use of longer, slower-turning, airfoil-shaped blades that allow the fan to move much larger volumes of air more efficiently than any standard ceiling fan.

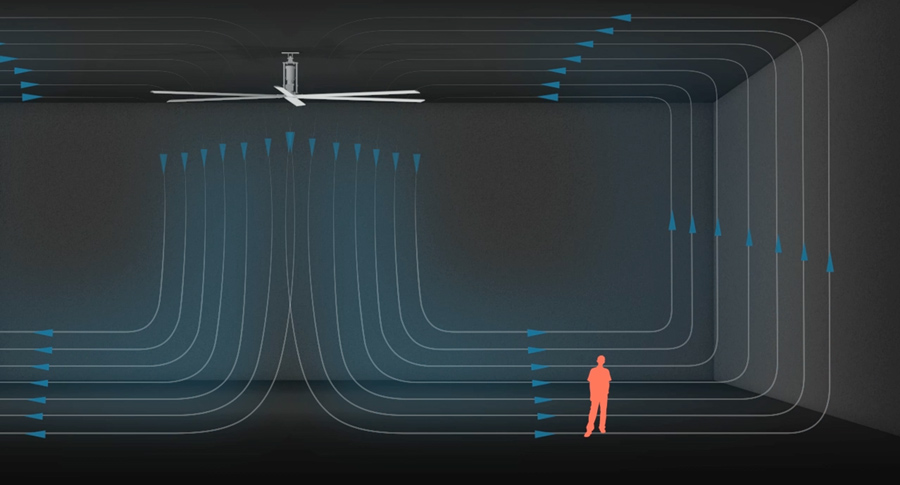

The HVLS fan creates a large column of air which is roughly as big as the total area of the fan. Further, the air column is pushed downward to the floor by the slow-rotating blades. When it contacts the floor, the air disperses evenly in horizontal directions, away from the column in all directions throughout the area creating a steady, yet gentle breeze that effectively cools everyone in the enclosed space. This air flowing outward is called the “horizontal floor jet”, the height of which is determined by the diameter of the column of air, a larger diameter fan naturally produces a larger air column and thus a higher floor jet.

Under the ideal circumstances, an 8 feet (2.4 m) diameter fan produces a floor jet of air approximately 36 inches (910 mm) deep, and a 24 feet (7.3 m) diameter fan produces a floor jet 108 inches (2,700 mm) deep, tall enough to engulf a human standing on the floor.

| HVLS FAN DIAMETER | COVERAGE RADIUS |

SPACE BETWEEN FANS | MINIMUM SPACE FROM WALL |

SPEED (in RPM) |

STANDARD DISTANCE FROM TOP |

STANDARD MINIMUM DISTANCE FROM FLOOR (OSHA STANDARDS) |

| 8 feet | 30 feet | 60 feet | 12 feet | 30-152 | 3.5 feet | 10 feet |

| 12 feet | 35 feet | 70 feet | 18 feet | 18-100 | 3.33 feet | 10 feet |

| 16 feet | 45 feet | 90 feet | 24 feet | 15-72 | 3.166 feet | 10 feet |

| 20 feet | 52.5 feet | 105 feet | 30 feet | 12-58 | 3 feet | 10 feet |

| 24 feet | 57.5 feet | 115 feet | 36 feet | 10-48 | 2.8 feet | 10 feet |

The HVLS fans, by maximizing the air dispersal, cause more efficient air circulation and also accelerate the evaporation of sweat from the skin to create the feeling of a cooler work environment. HVLS fans in combination with an A/C system can reduce the perceived air temperature by up to 7 degrees without lowering the thermostat.

The increased air circulation from an HVLS fan also allows a facility to raise its air-conditioning temperature to as much as 4 degrees while maintaining the same level of cooling comfort.

HVLS fans work in tandem with natural ventilation or HVAC systems. But HVAC systems alone have no means of mixing air; also ducting cool or warm air into a large space is not enough to create an even temperature throughout the facility. Once the right HVLS fan is paired up with the building’s HVAC system, the result is three-fold – a more comfortable climate, lower energy bills, and a system that works exactly the way required.

Advantages of HVLS fans

Energy-efficient: HVLS fans give about 30 per cent energy savings as it brings down the temperature by 4°C. Its running cost is about US $ 1 a day.

Incomparable warranty: Warranty is provided in terms of running-hours rather than years after purchase. HVLS fans are generally backed by number of running hours warranty which vary from 20,000 hours to 50,000 hours. Considering a run for 40 hours a week, 50,000 hours will be around 24 years. Also the product comes with a timer, and users can track the run time of the fans.

Zero maintenance: No gears, no oil, no friction – owing to gearless next generation direct-drive DC motor which is three times smaller yet five times more powerful – HVLS fans require absolute zero maintenance.

Lot of options: The HVLS fans come in 2-blade, 3-blade, 4-blade, 5-blade and 6-blade versions, and in 8-24 feet diameter.

Reduces ducting work: HVLS fans minimize the need for expensive ductwork in new construction for both heating and air-conditioning systems, and provide a constant even temperature from floor to ceiling and wall to wall.

Companies manufacturing and supplying HVLS fans

MacroAir invented the High Volume Low Speed HVLS fans for agricultural processes. Currently different models are available for use in various industries and warehouses. AirVolution D3 is a three-blade design which is specifically designed for medium to large spaces. With diameter ranging from 3.05 m to 7.32 m, spaced 16.80-29 m apart, AVD3 has a 1.05 horsepower direct-drive motor and weighs between 58.50 kg to 73.50 kg.

AirVolution-D550 and D780 are six-blade designs, designed specifically for medium to large and extra-large spaces, respectively. AVD-550 has a diameter ranging from 2.44 m to 5.49 m, spaced around 18.30-29 m apart and works with a 1.05 horsepower direct-drive motor. AVD780 comes with 6.10-7.32 m diameter, spaced 32-35.10 m apart and runs with 2.10 horsepower direct-drive motor. Both the models are equipped with AirBrain processor. If the fan is struck by an object, shaken by an earthquake, or bombarded by high winds, the AirBrain processor will detect the disruption and turn off the fan automatically. The processor also adapts to the building’s input voltage, generates and seamlessly resets fault codes, and integrates into building automation systems.

More and more industries are installing High Volume Low Speed (HVLS) fans as a complement to their HVAC systems. With an approximate price tag of US $ 6,000 for a 24 feet diameter 3-blade model, how the garment manufacturing facilities will adopt to the new generation technology, is yet to be seen.

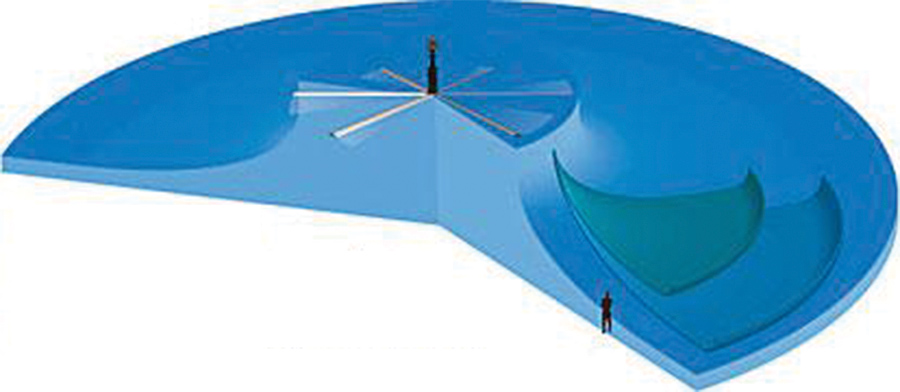

MacroAir also offers AirViz service which is a virtual installation model that precisely tracks the pattern and speed of the air in colourful 3D motion video. With this unique virtual “try before you buy” service, clients get a fully customized AirViz simulation of the proposed workplace.

Envira-North Systems Ltd. designs, manufactures and sells the most innovative ventilation solutions in the market today. Their HVLS fans are equipped with patented Tubercle Technology™ by Whalepower Corporation. The technology is a precisely engineered version of series of bumps applying to the leading edges of various rotors circulating fluids. These bumps on the edges of rotor blades enable more air movement, allowing fans to work quietly with less power usage. Tubercle Technology blades outperform all conventional air foils by offering stall angles as high as 22°, therefore always stalling gradually. This technology eliminates the primary cause of efficiency loss in all rotating systems, span-wise pumping and blade noise, damaging vibration, and tip stalling.

The Altra-Air model of the company comes with five blades and ranges from 3.7 m to 7.3 m (12-24 feet) in diameter and operates on 0.75 to 1.5 kw (1 horsepower to 2 horsepower). It is capable of moving nearly 188,000 l/s (3,97,701 CFM). Alite 3 is another three-blade model which minimizes weight while providing continuous air movement throughout the area of influence. A true cost alternative, these HVLS fans are available in 15’ and 23’ diameters operating on 1 horsepower and is capable of moving nearly 1,77,184 CFM. Envira-North’s safety system prevents a rotor from falling or a blade from coming off.

Rite-Hite is the world leader in manufacturing, selling, and servicing of loading dock equipment, industrial doors, safety barriers, HVLS fans, industrial curtain walls, and more – all designed to improve safety, security, productivity, energy savings, and environmental control. The two-blade model – The Revolution® is Rite-Hite’s original HVLS fan, standard for low cost, high-efficiency climate control. The fan features blade made up of aluminium with mill-finish standard and diameter up to 24 feet (7,320 mm), The Revolution is ideal for large facilities with high ceilings, as the end of a 20 feet-wide HVLS fan blade moves 10 times faster than its base, requiring a twisted and tapered shape to maximize air movement.

The Revolution® 4-blade model has unique Propell-Aire blade design that has a complex contoured shape (tilt, taper and twist) that varies along the length. It is the shape, not the number of blades that generates the large volume of air movement needed for an effective HVLS fan. The fan has hub connection which is critical since exactly like the blades of a helicopter, a combination of centrifugal force and air pressure causes the blades to move upward during the operation. These fans possess a three-way motor-to-hub safety connection. When the Revolution® starts funtioning, air is pulled from the above and pushed down in a conical shape to the floor. Air travels in this conical shape until it hits the floor and then moves in a horizontal stream away from the diameter of the fan. The fan will move air up to 85 feet or 50 feet from the fan’s centre in all directions.