Modular manufacturing, teamwork, group systems, self-managed work teams, drum buffer rope manufacturing, Toyota Sewing System (TSS), flexible manufacturing, lean manufacturing and a flurry of other terminologies, are commonly used for a system of assembling garments where a small group of workers share work content to complete the sewing of one garment. However, there are many wrong notions about teamwork.

In common parlance, teamwork is a group effort where all operations of one garment are done by a small group of multi-skilled operators where benefits of division of labour and special machinery and infrastructure are optimally utilized. In teamwork sewing typically there are no supervisors, or quality checkers. Team members are empowered to take decisions themselves (often through team leader), self-check and are not allowed to make any defective pieces. In case of any defective piece produced, team members themselves have to discuss and resolve the problem.

Somewhat similar to progressive bundle unit (PBU) working principles, multiple members in the teamwork concept can start work on different components simultaneously, and gradually finish in a converging flow of materials where usually one operator completes the last operation. The operator may work in seating position, can maintain a healthy work in progress (WIP) between operations. This was necessitated in the Western countries in response to market pressure of quick response to retail sales as well as to reduce occupational health injuries associated with PBU. The objective was to minimize long lead time of PBU system, and reduce ergonomic vulnerability of repetitive work through job rotation.

One particular extreme form of teamwork called TSS, in fact, revolutionized and popularized this concept amongst industry practitioners, although not necessary or mandatory for any team to follow. This generated and/or necessitated some associated practices and jargons that became synonymous with teamwork. In TSS, group of operators work in PBU/UPS system in a standard sewing mode where there are more machines than number of workers.

Single piece flow is mandatory for teamwork sewing

Wrong

To reduce sewing lead time, it is mandatory to reduce Work in Progress (WIP); however it is not mandatory to have a single piece work flow. Team can work with any number of pieces as long as lack of WIP does not hamper production of any operator. Actually while working with bare minimum WIP the concept of KANBAN (Kanban means visual signal in Japanese) is followed. The last operator of the team visually controls the maximum WIP that can be kept between any two operations. The kanban concept helps convert the flow of material from push to pull. Once the last operator picks up pieces from WIP bin to work, the predecessor operator gets a kanban signal to replenish the WIP, so he/she picks up pieces from previous bin to work, thus creating a kanban signal to predecessors’ predecessor operator and this way the signal goes down the line till the first operator.

Practitioners and enthusiasts kept reducing the WIP from number of bundles to zero, thus popularising the concept of single piece flow (also called ‘zero WIP’ concept). The moment the WIP becomes single piece, the component actually started moving from one operator to another.

Interestingly the pieces in the teamwork are not passed on from predecessor to successor, rather the operator actually takes the piece from predecessor and keeps working till his/her successor takes the piece from him/her. (Thus the jargon ‘hands-off’ originated).

WIP generally buffers the disparity or gap in the work content of different operators. Gradual decrease of WIP to single piece necessitated operator to hand over the piece to next operator rather than disposing it in the bin to be picked up by next operator.

Teamwork sewing is always done with machine-to-worker ratio of more than one

Wrong

It is always possible to have teamwork sewing with machine to operator ratio as 1:1. Teamwork demands sewing operations to be grouped together based on the required pitch time, similar machines and skill of operators. While grouping the operations from PBU to teamwork, sometimes it is felt that different types of machines/attachments are necessary while work content is very less. In high labour cost countries it was also felt sensible to keep number of operator as minimum as possible. So more number of machines’ work was allocated to less number of operators. In extreme form of teamwork in sewing, i.e. TSS, the number of machines is higher than number of operators and typical ratio is of 5:3. This means for every 5 machines there are 3 operators. For a 5:3 machine to operator ratio, the maximum machine utilization is 60% as 2 out of 5 machines are idle at any given point of time. This ratio is workable in the higher labour wage countries where cost of maintaining a worker is higher than cost of maintaining a machine. As the machine utilization is very less, the machine productivity is also less compared to PBU system of working.

Why stand up sewing? Stand up workstation is mandatory for teamwork sewing

Wrong

In a higher machine to operator ratio scenario, operator needs to get up from one machine, walk up to the next, sit and position and then only start work. Lot of time is wasted on unproductive work which require maintaining huge WIP. To reduce the unproductive time, ‘stand up’ workstations were introduced where special double pedal operations (and many other high technology features) are present, so that team workers can move from one machine to another and start work instantly without wasting much time in settling down. The PBU system was also vulnerable to RSI (Repetitive Strain Injury) of upper body parts which were eased in stand up sewing. The stand up sewing also facilitates single piece movement as successor operator actually walks up to predecessor operator to fetch the piece. In high intensity production situation, the successor operator actually bumps back to predecessor operator and takes the pieces (Thus the jargon bump-back system started).

U-shaped layout is mandatory for teamwork in sewing

Wrong

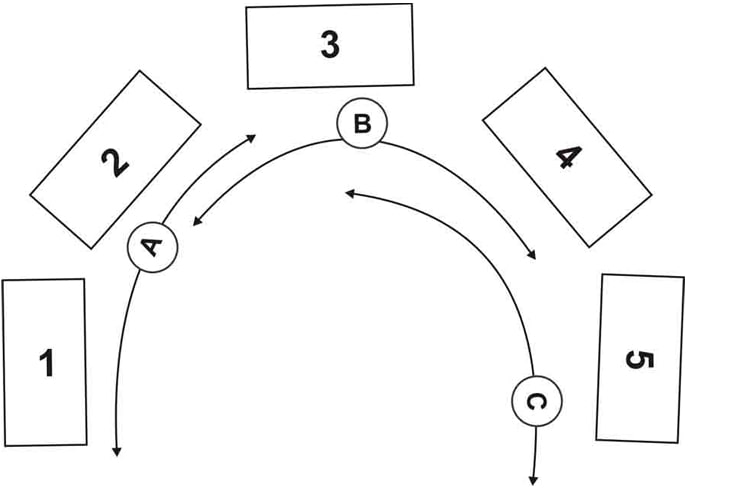

The machine layout in teamwork can be of any shape. However in TSS, where one operator is supposed to move from one machine to another, the walking time should be bare minimum. Therefore, the machines are arranged in U- or C-shaped layout, so that operators can reach different machines much faster. In the given diagram, if an operator has to reach from 1st to 5th machine, he/she can just turn around and reach, whereas in linear layout he/she has to walk long distances. In case machine to operator ratio is 1:1, operator need not move between one machine to another, so machine layout does not matter. Even when machine-to-operator ratio is more than one, but work in progress (WIP) is large, then frequency of movement of operator from one machine to another is less; therefore traditional linear layout is ok.

Stand up sewing system can be tiring for workers

Wrong

In fact this is a mind block. On manufacturing floor itself there are many operations which are done in stand up mode, such as ticketing, ironing, cutting and many more. The moment we think of sewing, we visualize sitting operation. In reality, double pedal control, tummy or voice activated sewing, laser alignment of piece can deskill the sewing process and bring comfort level as well.

Teamwork sewing helps to reduce throughput time

Right

Throughput time is a factor of SAM value and WIP in the line. Low WIP (or zero WIP in single piece flow) directly cuts down the waiting time of partly sewn pieces, which otherwise are languishing in PBU system. Therefore, teamwork reduces the throughput time by reducing the waiting time component.

Teamwork sewing always results in higher operator utilization

Right

Operator utilization in PBU system depends on balanced efficiency of the line. In a poorly balanced line, a significant time is wasted by operator waiting for the pieces from predecessor. In TSS teamwork sewing, the line is self balanced; there is always a piece in every operator’s hand. Theoretically, operator utilization is cent per cent.

In TSS system, operator snatches pieces from the predecessor, which may create quality problems

Wrong

Actually due to hands-off system, sometimes operator leaves a sewing operation midway (half way) allowing the successor operator to complete. This may sound unrealistic for those associated with PBU or makethrough system. In TSS, the machines are armed with deskilling devices to the teeth. A folder/guide and needle positioning system ensures that work piece is not shifted during the changeover.

TSS in sewing results in lower machine utilisation

Right

TSS works with machine to operator ratio more than once. As number of machines are always more than operator, and operators move from one machine to another at any given point of time some machines are always idle. Therefore, machine utilization is very less in TSS.