Fashinza, a global B2B apparel manufacturing platform headquartered in India, has announced to expand services to New York (USA) in partnership with a few leading brands.

The business model of Fashinza includes solving some of the toughest apparel supply chain challenges by helping apparel brands to work directly with manufacturers in a transparent manner, with the help of their unique digitised supply chain.

Backed with funding from Accel Partners and Elevation Capital, Fashinza seems equipped to carve their space in New York’s apparel industry, with the goal of reinventing the US $ 800 billion global fashion manufacturing business for the e-commerce era.

According to the company, the pandemic has caused great levels of turmoil in the global apparel industry and the structural issues that were dependent on long lead times, high cost of operations, low efficiencies and huge inventory problems have now been exposed.

“Moreover, it’s surprising that in the age of Amazon and Shopify, the supply chains are still managed on emails and spreadsheets. The mammoth coordination effort without technology results in delayed deliveries and long turnaround times,” reads a Press Release of Fashinza.

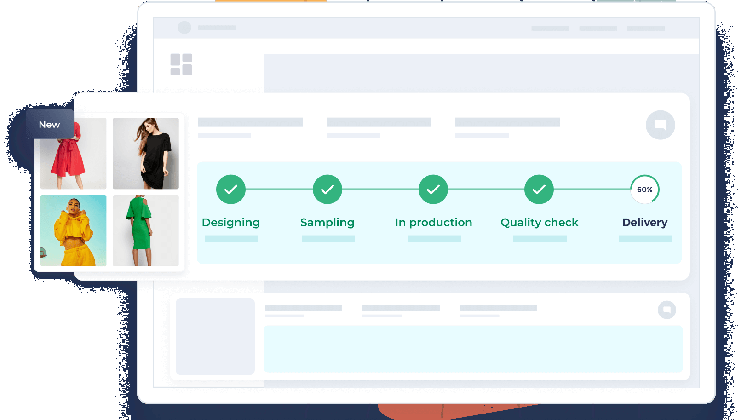

Fashinza’s platform allows apparel companies to track the daily progress of their orders on an AI-regulated dashboard, with live updates from the factory floor, eliminating the need to make a hundred calls and emails for follow-ups. It also helps brands to reduce wastage, inventory forecasting errors and enables quick replenishment of bestsellers with a fast turnaround time.

Pawan Gupta, Co-founder, Fashinza, said, “For fashion brands, outsourcing overseas comes with a whole lot of challenges – from finding an ethical supplier to implementing quality checks – the pain points are numerous. Our policy of ‘complete ownership’ solves this problem for brands since we take care of the entire production process from designing to delivery.”

Pawan further averred that they have all seen cases where clothes were being manufactured under dangerous conditions and the brands were oblivious to it.

“This is not just a risk for the concerned brand’s reputation but is also a humanitarian crisis. By making ethical working conditions a mandate for all our partner factories, we ensure our associate brands never have to worry about these problems,” concluded Pawan.