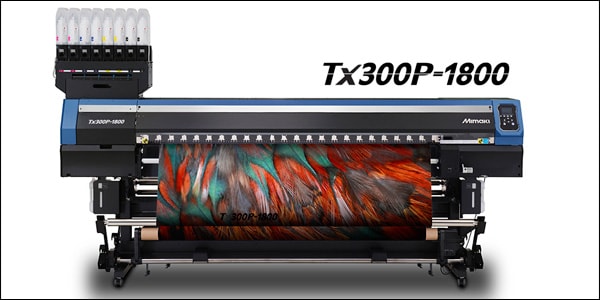

Mimaki USA, a leading manufacturer of wide-format inkjet printers and cutters, has announced the availability of the TX300P-1800 roll-to-roll, direct-to-textile inkjet printer for order in the Americas.

Also Read – Mimaki to unveil UV-curable inkjet printers next month

The 75-inch wide printer is engineered exclusively for direct-to-fabric applications and is capable of utilizing five types of textile-specific inks that can be directly printed on a wide variety of synthetic or natural fabrics.

The TX300P-1800 printer includes advanced piezo electric print heads enabling printing on various types of textiles ranging from fine to heavy denier, woven patterns or raised fibre surfaces, while maintaining accurate ink droplet placement. With optimum waveform control, the print head jets each ink colour at the appropriate jetting angle without losing precise ink droplet circularity.

Incorporated with a reliable textile handling system, the printer uses a combination of tension bars and drive rollers to maintain the appropriate tension, for any variety of textile used. The Auto Media Feeder applies calibrated tension to the media used, maintaining stable and precise media feed and take-up on rolls.

Also Read – Mimaki launches new UV LED flatbed printer

Besides, Mimaki’s direct-to-fabric printer is incorporated with Mimaki Advanced Pass System 4 (MAPS4) technology which reduces banding, uneven ink drying and bi-directional stripes, resulting in smoother images with no distinct bands. The machine is also equipped with Mimaki’s TxLink3 Lite software that delivers exceptional colour management and colour replacement. Moreover, NCU (Nozzle Check Unit) and NRS (Nozzle Recovery System) assure high quality transfer prints by providing continuous printing and minimize waste by ensuring any clogged nozzles do not reduce the print image quality.