You never change things by fighting the existing reality. To change something, build a new model that makes the existing model obsolete,” said American architect Buckminster Fuller.

That idea captures the quiet revolution happening in the apparel industry, from the cutting table to the cloud. From cutting rooms to finishing lines, digital tools are reshaping what efficiency, accuracy and sustainability mean in practice.

At the centre of this change is precision. For instance, modern marker-making and nesting systems have evolved far beyond layout planning. They now optimise fabric usage down to the last centimetre, accounting for every variable such as width, grain direction, defect zones and tilt angles. Multi-core processors and auto-compaction features enhance speed and yield, while visual interfaces allow technicians to rotate and align complex fabrics like stripes, plaids and lace with absolute accuracy. What once took hours of manual tweaking can now be simulated, refined and completed in minutes.

But material optimisation is just one part of a much bigger shift. The traditional ‘island’ approach, where planning, production and maintenance ran separately, is giving way to unified digital ecosystems. These factory operating systems bring every process together under one roof. Supervisors can see live production data, defect trends and work-in-progress updates on a single dashboard, reducing delays and decision gaps.

Crucially, these systems don’t demand that factories change who they are. They adapt to how each one works. With features like offline data validation and multilingual interfaces, technology becomes easier to adopt, even in regions with connectivity challenges.

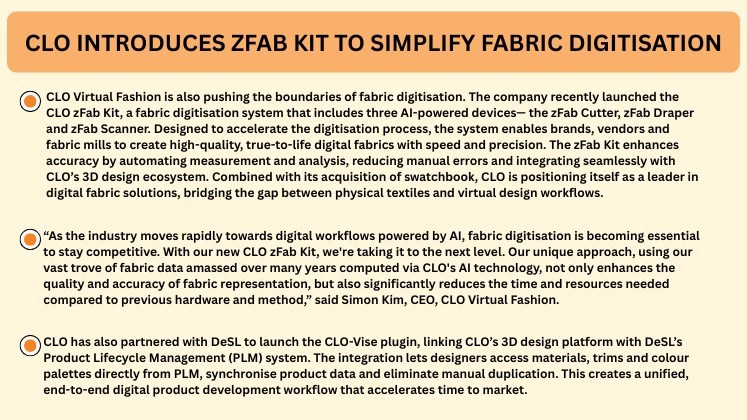

And upstream, in design, the next transformation is unfolding through fabric digitisation. Using AI-driven scanners, cutters and drapers, manufacturers are turning physical textiles into high-fidelity digital materials that capture the fabric’s texture, drape and stretch. These 3D-ready assets enable faster sampling, fewer approvals and more sustainable workflows.

Smart Tools for a Connected Factory Floor

Experts note that while digitalisation offers clear benefits, each manufacturer’s priorities differ.

“When we enter a factory, we start by understanding how work actually flows. Everyone asks for visibility, but nothing changes until the data foundation is fixed,” said Anuj George Kurian, Chief Business Officer, Solvei8. The cloud-based platform operates across India, Bangladesh, Sri Lanka, Indonesia, Vietnam and Myanmar, digitising planning, production and quality through its Factory OS suite.

He added, “This is why Solvei8 has focused on fixing the data pipeline. When planners and production teams get real-time, validated information, they finally move in sync. Timely data turns planning into control and production into flow.”

This is the gap Solvei8 has solved. Customers such as Arvind, Matrix Clothing, Texport, Shiva Texyarn and Premier Knits now operate on a unified, validated data layer that helps teams make decisions faster and with far less friction.

Other digital solution providers driving similar change include STITCH, MES, Jaza Software, Coast Digital, Method Apparel, CTeBS, Codeverse, WFX, BlueKaktus and Datatex.

Whereas, players like Optitex, which develops end-to-end fashion design software including 2D CAD/CAM pattern design and 3D prototyping for fashion, apparel, automotive and upholstery, are taking precision a step further with digital solutions that streamline fabric use and design. Its Nest++ marker helps optimise fabric consumption by arranging pattern pieces in the most efficient layout.

Features such as Parallel Nesting, Spacing Optimizer and Auto-Compaction reduce waste and save time, while Match++ ensures perfect alignment for striped, plaid and lace fabrics. Specialised options for leather and lace nesting further improve yield and quality.

Optitex also offers three levels of automated nesting: Basic (Nest++), Advanced (Nest++2) and Professional (Nest++Pro), delivering up to 4% higher fabric efficiency compared to manual methods. The system can generate detailed reports on cut orders, marker files and fabric rolls, helping factories plan material use and control costs more effectively.

Its Fabric Meter application completes the loop by digitising fabric testing—measuring stretch, stiffness, weight and thickness in under 15 minutes, then storing results in a shared fabric database for design and production teams.

Beyond cutting, Optitex’s Pattern Design Software integrates 2D design and 3D visualisation, allowing manufacturers to create, simulate and refine products faster while ensuring a better fit.

“When we sell the nesting solution, it serves two key purposes—production and costing. Some customers use it to run simulations to measure efficiency, which directly affects cost calculations. This data is often shared as part of the costing process. It’s a good example of how we connect buyers and suppliers, allowing them to exchange efficiency and costing information seamlessly,” said Frank Maeder, President of NedGraphics and Optitex.

He noted that today’s designers are fluent in Adobe tools, so Optitex and NedGraphics now offer 3DDI and Adobe plug-ins to make adoption easier for this new generation.

Likewise Browzwear, Tukatech, Lectra, Optitex, CLO3D and Style3D are advancing in the same direction.

| “When we enter a factory, we start by understanding how work actually flows. Everyone asks for visibility, but nothing changes until the data foundation is fixed. When planners and production teams get real-time, validated information, they finally move in sync.” – Anuj George Kurian, Chief Business Officer, Solvei8 |

| “When we sell the nesting solution, it serves two key purposes—production and costing. Some customers use it to run simulations to measure efficiency, which directly affects cost calculations. This data is often shared as part of the costing process.” – Frank Maeder, President of NedGraphics and Optitex |

The Hurdles of Going Digital

Apparel factories may look more digital than ever, but beneath the surface, the transformation is still incomplete. Despite major strides, efficiency gaps and data silos remain stubborn challenges.

Anuj noted that slow processes such as GRNs (Goods Received Note) taking hours to update often leave planners stuck. Even the most digitized functions like planning and production scheduling struggle without timely, accurate data. “People end up reacting all day instead of actually running the day,” he said.

That’s why solution providers aren’t rushing into AI. The industry first needs a strong foundation of accurate, real-time data before moving towards automation or advanced analytics. Many current ‘AI’ tools are still rule-based, unable to handle the complex, interlinked nature of apparel production. Real AI needs continuous learning from live data, something most factories don’t yet have. Another roadblock is the lack of openness amongst technology providers. Most build closed systems, forcing manufacturers to use only their products.

Maeder added that while the apparel industry is evolving, it still relies heavily on physical sampling, one of the biggest barriers to speed and sustainability. Digitisation offers a clear solution, but challenges persist. “It’s extremely difficult to represent fabrics accurately in a virtual environment,” Maeder explained. “Texture, thickness, surface effects and colour, all behave differently under changing light and conditions.”

“We have some experience addressing this through NedGraphics, but it’s still a very complicated problem to solve. In industries like automotive, conditions are more controlled, so investments in colour-accurate systems are feasible,” he admitted.

However, experts sounded optimistic that as data becomes faster, systems more connected and visualization more lifelike, apparel manufacturing will shift from isolated systems to an ecosystem that learns, adapts and creates in real time.