Chargeurs PCC, a leading name in the production of interlinings and inner components for apparel, recently showcased its latest innovations at 2024 Bharat Tex in New Delhi, the global textile event focusing on sustainability and resilient supply chains. Chargeurs PCC presented the Lainière Paris, Bertero and Fusion Line collections and GMP and weft-insertion technologies at the fair, among other products.

Gianluca Tanzi, CEO and Chairman of Chargeurs PCC commented, “India is the key market for the future, with its rich textile heritage, skilled workforce, and immense potential for growth. By participating in this trade fair, we aim to showcase our exceptional range of inner component solutions and our commitment to innovation, sustainability, and Made in France quality that aligns perfectly with the emerging trends and demands of the Indian textile industry. Through our participation, we are sure to engage with industry professionals, forge strategic partnerships and further establish our presence and strengthen our position as a leader in the interlining industry.”

Lainière Paris has been the leading knitted interlining collection for over a century, supplying the world’s most important haute couture and ready-to-wear fashion houses. Made in France at the historic Lainière de Picardie factory in Péronne, Lainière Paris interlinings combine lightness, fluidity and softness with an imperceptible and delicate coating, perfect adherence, and bi-elastic properties.

Chargeurs PCC also presented its exclusive GMP technology for coating process and weft-insertion technology. The unique Global Molecular Point (GMP) process, patented by Chargeurs PCC, was created to develop a coating with optimal adhesion for a diverse range of fabrics, while preventing strike-through. GMP ensures ideal garment stability over time, respecting the integrity of the fabric and preserving its flexibility and durability.

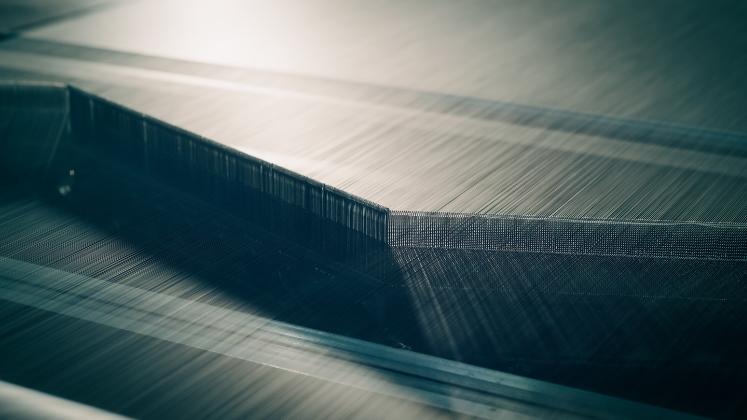

Through close collaboration with Karl Mayer, a leading figure in textile machinery construction, innovative machines featuring weft-insertion technology were developed. The weft-insertion technology allows for the incorporation of supplementary yarns across the fabric’s weft direction. This opens up a wider range of design possibilities while enhancing fabric quality and performance. The technology delivers remarkable resilience and recovery in the weft direction, while ensuring breathability, high stability and control in the warp direction.

Chargeurs PCC offers end-to-end solutions for the world’s leading fashion houses, designing and producing interlining, the technical fabric used to help garments maintain their shape and structure. It produces more than 350 million metres of interlining a year serving more than 7000 customers. It has a global presence with 8 production sites, 21 testing laboratories, 39 subsidiaries and sales offices and more than 1000 employees worldwide. It serves more than 90 countries on all continents. It includes the Senfa division which provides innovative coating solutions. Chargeurs PCC Fashion Technologies is part of the France-based Chargeurs Group, listed on Euronext Paris and founded over 150 years ago.