A charming perspective: No stitched seams anymore. Real seamless, on the other hand, still is an exception, like the “seamless” circular knit technology by Santoni and the full garment flat knit technology with Stoll or Shima Seiki knitting machines. Meanwhile, the ultrasonic welding technology moves forward to more and more sophisticated machines which are adapted for the making-up industries.

Ultrasonic welding can be a state-of-the-art technology for high-tech or non-wovens materials and for special applications like waterproof seams, very flat seams, non-wovens and combining textiles with foils and films. One thing is certain: ultrasonic welding won’t replace the traditional sewing for all kinds of applications.

Claudia Ollenhauer-Ries from Germany, reports.

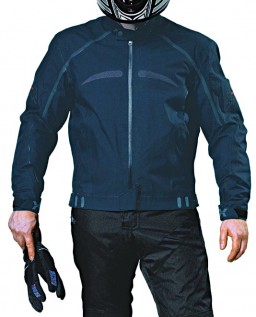

Classic sewing with needle and thread will continue to be the first choice for many applications in textile – from apparel to all kinds of technical uses. The thread is a new component introduced into the work piece. This matters in special cases, where homogeneity of materials is important or the failure of possibly weak components could be disastrous. The fact, that the needle punches holes into the material of the work piece, matters again in special cases, where the holes could damage the super fine knitted material (40 gsm and more) or spoil the liquid, gas or vacuum tightness of the fabric (for example in rainwear, sterile garments, clean room garments or airbags, etc.). In other cases, a traditional seam means more thickness, which is again not desirable for athletic clothing for swimmers and runners, or for body suits.

The ultrasonic welding technology can be the alternative for these, and certainly for a few more applications.

Definition of Ultrasonic Welding

Ultrasonic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld. It is commonly used for plastics, and especially for joining dissimilar materials. The development of the ultrasonic technology started in 1960s for metals and thermoplastics. Common frequencies used in ultrasonic welding of thermoplastics are 15 kHz, 20 kHz, 30 kHz, 35 kHz, 40 kHz and 70 kHz. For textiles it is usually between 20kHz and 40 kHz.

Two processes are commonly used for textiles: The pure welding of materials and the gluing of two materials with an adhesive film or band.

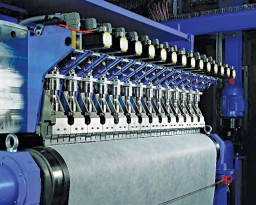

For ultrasonic welding two types of machines are used – First, machines with a fixed sonotrode and a rotating wheel for fast and precise welding (especially for curves) and second, machines with a rotating sonotrode and a rotating wheel for fast welding (for straight seams).

Few disadvantages of Ultrasonic Welding method are:

1. The material thickness can only be limited, as the outer layer may burn from a certain thickness before the inner layer plasticizes.

2. Current limitation of ultrasonic welding is natural fibres. Synthetic fibres with natural characteristics (feel, comfort, moisture regain, etc.) will have to be developed.

As against hot air machines or heat presses for gluing, the ultrasonic technology generates heat only where and when needed. The machine stays cool, the operator will be safe from burnings and the surroundings won’t be heated. More than that, the material can stay for any period of time in the machine without being scorched. In terms of speed, ultrasonic machines can be much faster than hot air machines, which have to wait for the glue to melt. Ultrasonic welding needs significantly less electricity than thermal bonding.

Applications for Ultrasonic Welding

The list of possible applications is long and adds new fields to the classic sewing applications: underwear, outerwear, outdoor clothing, active sportswear, medical products, clean room clothing, technical textiles of all kinds, automotive textiles plus non-wovens and packaging.

Ultrasonic welding is used for:

- Joining fabrics edge to edge without seam allowance,

- Joining fabrics by overlapping with seam allowance,

- Hemming without seam – fixing the edge,

- Hemming with seam,

- Hemming with elastic or not elastic band,

- Straight superimposed seam with cutting in case of home furnishing,

- Ribbons and trims, and

- Ballistic vests and body armour.

Depending on the material, all processes could be executed by bonding with an adhesive film or without it. Thermo sensible materials can be processed without adhesive film; other materials need an adhesive film.

Types of Fabrics Suitable for Ultrasonic Welding

The materials should match several requirements: A broad melting range, a high coefficient of friction, uniform thickness, 65% minimum thermoplastic content, sufficient rigidity and thickness to accept energy at the material interface (0.0005 inch/0.0127 mm minimum). Polyester is considered to be a good material for ultrasonic applications. Apart from polyester, Nylon 6 and Nylon 6.6, polypropylene and polyethylene have good ultrasonic characteristics. Others are acrylic, urethane, polyvinyl chloride (PVC).

The fabrics could be knitted, woven, non-wovens, laminates or coated materials. Films can be added to the textile surfaces.

Whatever be the case, preliminary tests should always be done. Some of the machine suppliers offer testing facilities in their own laboratories.

Selected Suppliers of Ultrasonic Welding Machines

A leader in this area is Schips, Tuebach from Switzerland. The company has over 50 years of experience in sewing automation in the apparel and underwear sector and added the ultrasonic technology to its portfolio. The company offers a high degree of consulting and much specialized machine configurations depending on the need of the customer. Martin Schips, CEO of the company, talks of “plug & play” solutions including optimized details for the welding process.

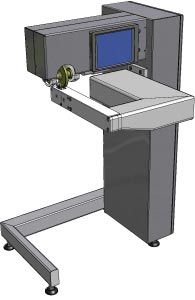

Nucleus, Duesseldorf, Germany has continued to develop the ultrasonic welding technology further for the application on technical textiles, non-wovens and films. The Nucleus Rotosonic V4E is a multi-purpose machine in four variants for flat fabrics, 3D-parts, small parts and preforms. The flatbed machines can be equipped with pillars and downward arms simply by plug & play. Also the wheels can easily be changed. Nucleus offers a retro-fit module for the Pfaff Seamsonic machines.

The new Pfaff Industriesysteme und Maschinen AG, Kaiserslautern from Germany is focusing on innovative sewing and welding solutions under the PFAFF brand name. At IMB they showed the 8310-144 which is a new ultrasonic welding machine with patented double wheel solution. The welding and cutting wheels can be set separately on the 8310-144. This is used for welding and cutting synthetic textiles.

On the Pfaff Seamsonic 8310 parameters such as speed, pressure, etc. can be preset using touch screen controls for each type of fabric whilst layer detection devises change these parameters automatically to cater to different thicknesses and types of materials. The company caters for the sportswear, airbag, waterproofs, medical and protective work wear markets, as well as the filter industry, and many of the machines are individually made to customer needs to provide the best solutions.

Sonobond Ultrasonics, West Chester, USA, is a pioneer in ultrasonic welding. The applications range from metal to plastic and textiles respective non-wovens. Among the machines offered are hand-held compact units suitable for cutting and bonding lightweight synthetics, non-wovens and plastic films. SureCut HC35 has been designed for specialized applications in the textile and plastic film markets. This unit cuts and seals the edges of non-wovens and synthetic fabrics and films in one quick step. It can also accommodate double layers of fabric, as well as single slits of ribbons, labels, and Velcro strips.

TFT (Textile Fusion Technologies), Konken from Germany, cooperates with KSL, Kaiserslautern, Germany to offer special ultrasonic welding machines for technical textiles and apparel applications. TFT develops the welding systems while KSL designs and constructs the robotics. Its main focus is to produce customized machines for the technical textile market, one example being a special ultrasonic welding machine for continuous welding and cut welding of pleated filter media.

This machine incorporates a special guide devise, variable height pleating, variable length of pleated filter, lowering and lifting of the anvil roller by pedal with manual adjustment of welding power output, stop and start.

Welding seam width varies between 2-10 mm depending on the anvil roller. The roller and the sonotrode have separate differentiable drives and welding speed varies between 0.3-7 metres per minute depending on material.

Ever Green Ultrasonic is based in Taipei, Taiwan and offers a series of standard ultrasonic machines for lace “sewing”, rhinestone application, surgical gowns, cutting, stitching and sealing.

Sonic Italia from Rho, Italy, focuses on cutting and sealing of technical textiles and on spot application for cutting and sealing. The ultrasonic slitting method works with a moving fabric and a stationary ultrasonic unit. It produces cuts with smooth edges and can join two or more layers of substrates. The traversing mode works with a stationary fabric and the ultrasonic unit moving across the fabric. This method is used to cut materials to length. In the plunge method, the material remains in a fixed location and is periodically contacted by the machine, which cuts and seals the material. This method is applicable for filters, bra straps, belt loops, and buckles or embossing.