According to the World Bank, 20 per cent of water pollution globally is caused by textile processing. Fabric dyeing process is a big source of water footprint, dumping wastewater into streams and rivers poses an especially big problem. Moreover, it is hard to say that the chemicals used to process the fabrics will not harm the skin of the cloth wearer. The textile and apparel industry’s challenge is to adopt more water-friendly technologies to dye cotton and polyester, the two most mass marketed textiles.

Even in USA, which is the largest apparel market in the world, textile production has been suffering due to water crisis especially, Los Angeles and California suffered a lot during 2015-2017 period. Mitigation of the effects of this toxic and water-based dyeing process has become a necessity. With an aim to bring back ‘sustainable’ apparel production in the country, USA-based Apparel Made for You (AM4U) offers the solution of above-mentioned challenge particularly for MMF. Its Active Tunneling Infusion (ATI) coloration technology replaces huge water-based dye houses as no water or hazardous chemicals are used in dyeing process.

Active Tunneling Infusion (ATI)

Active Tunneling Infusion (ATI) is a replacement for both traditional wet printing and chemical dye processes. Developer of this technology, Bill Grier, who is also the Founder and President of AM4U, cites that the technology revolves around one simple concept: the fibre itself contains enough energy to conduct colorization from the energy stored in the fibre, rather than requiring external chemicals to create colour. “What I found is that there was energy stored in the fibre when it was man-made that we could release at certain frequencies,” Grier said to Apparel Resources.

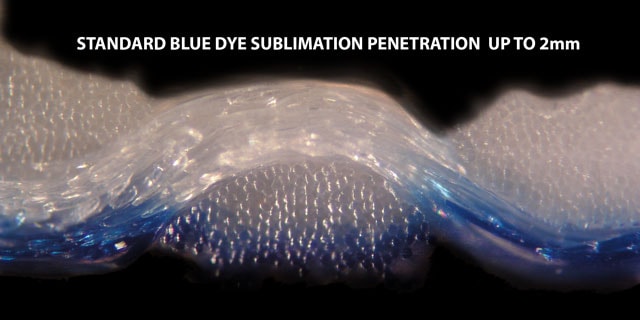

Active Tunnel Infusion (ATI) as a process for particle infusion into polymeric solids uses emitters at the harmonic frequency of the fibre to activate the amorphous portion of the fibres construction to form tunnels with active ripplons (waves) that suck the dye deposited on the surface into the fibre. When the frequency emission subsides, the tunnels contract and seal the dye in the fibre, safe from outside agents like bleach or detergents. The amplitude of the frequency controls the depth of the colour allowing both dyeing and printing to occur on both sides of the fabric in a single pass. Man-made polymers store more energy when they are formed and therefore are more responsive to ATI, natural fibres tend to expand excess energy during growth and may accept colour but are less likely to seal and protect the colour from outside agents.

Bill further explains, “Using energy multipliers ATI vastly improve the energy conservation, product differentiation, and economics of traditional dyeing and wet printing. Using pulsed energy for dye placement and capillary tunneling for penetration and leveling, ATI replaces the toxic reactive chemistry and water processes of traditional dyeing and printing.”

ATI also provides significant improvements in colour stability and inventory control. The Active Tunneling process uses a unique combination of energy emission and transmission environments to multiply the energy efficiency and control needed to produce permanent repeatable coloration of fabrics and other materials. All coloration processes include three steps: Placement of the colour (dye), penetration of the receiving fabric and leveling of the colour to create a permanent and even appearance.

Simply put, it can be said that all polymer fabrics contain amorphous and crystalline structures. The density ratio and elasticity of the regions between these structures determine the effectiveness of the Active Tunneling process in providing a printing or dyeing solution.

According to Bill Grier, this green cost-effective technology has caused a huge shift for the apparel industry in the USA. “ATI is switching supply-and-demand concept to demand-and-supply approach,” informs Bill.

Benefits of ATI Coloration Technology:

The colours produced by this method are so permanent that one could pour bleach on it and the colors will never change, Bill claims. Cleaning agents or bleach cannot affect the coloration of the fabric, resulting in the most durable colored fabrics available. Since water is eliminated in the AM4U colour application process, production is simplified.

Moreover, this technology allows color changes on the fly, any colors and different colors for each garment that includes all over prints and graphics. This process will eliminate finished goods inventory and the related carrying costs will increase retained gross profits by up to 100 per cent.

Most fabric coloring requires mass production through multiple processes and factories, which often result in excess fabric from over-estimating production. This technology enables dying, printing, and labeling only the amount of fabric needed, all on one machine in a single pass and on a much quicker schedule, instead of a designer having to place an order overseas to separate dye houses and printing manufacturers.

Grier said this technology could help bring the textile industry back to the United States instead of relying on large-scale mass printing and production overseas.

“Four out of every five blouses produced overseas are not sold at retail price. That means, we’ve produced four blouses more than we need for the marketplace, and the water use is somewhere around 100 to 150 gallons of water per blouse, so if we don’t produce four of them because the technology is closer to the consumer, we’ve saved water and caused less pollution,” Bill explained. He went on, “Water is becoming a precious commodity, especially in California, and without waterless technology we lose the ability to control our own destiny on the products we produce in California.”

Upon asking how did Bill make it possible to use no water and hazardous chemicals using ATI technology and is there any substitute of water and chemicals, he explains that the process is built on physics not chemistry and the colorant used is generally inert. Since the dye and print are colour-fast at exit from the unit, no post treatment or washout is required.

Making people convinced about the technology is the key…

A certain technology comes with a certain cost and many apparel manufacturers refrain from investing in technologies other than production processes. But, ATI claims to have a much lower capital investment and when made a part of an Integrated Micro-Factory, there is very little setup or clean up. “When integrated with the proper merchandising system the increase in profit is dramatic and even without vertical integration, profit increase can be substantial,” boasts Bill.

However, development and market quality testing of this technology are complete but widespread adoption is awaiting commercial sponsors and further expansion of the demand manufacturing base. “The patent is still in process, as some language has had to be adjusted during review. Discoveries are very difficult to patent, they don’t easily fit in the definitions examiners use like ‘utilities’ or ‘process’ but I am hopeful to see ATI getting patented soon,” concludes Bill on an optimistic note.