Pattern tacking applications range from simple bar shaped tacks in trousers to large area pattern formation for car air bags, etc. This article, last in the series on Sewing Technology, will focus on the different levels of technology solutions available for an operation, makes and models of machinery and equipment available in the market and also Return on Investment (ROI) comparison for the basic and highest level of technology.

Articles on technology for spreading and cutting, piped pocket making, time and motion study, dart making, shirt finishing and belt loop attaching have already been published in earlier issues of StitchWorld. This article by Parul Singh a student of B.F. Tech (Apparel Production) and Professor Prabir Jana, Chairperson, Dept. of Fashion Technology, NIFT takes you through the technology options for various needs and for various scales of operation. As always, wise investment yields the best value for money.

[bleft]Bar tacking is the most simplest form of pattern tacking; simple shape, small area covered under clamp and simple mechanism, but most universally used”[/bleft]

Pattern tacking is the term used to describe the sewing of small stitch patterns, which are generally used for reinforcing other garments. It can be done in various shapes such as square, rectangular, triangular, bar, semicircular, and so on.

Apart from the functional use (i.e. reinforcement), pattern tacking is also used for aesthetic purposes like semicircular tack in piped pocket end, cross tack in Velcro attachments for cargo trousers, among others.

Basic Level of Technology (Manual Operations)

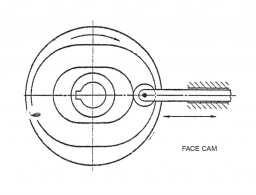

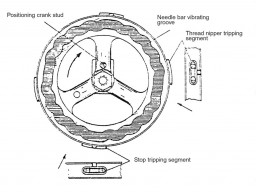

The sewing patterns are generally limited to a specific number of patches in the range from 10 to 100 stitches per pattern and cover only a small area of workpiece. This operation is performed by moving the workpiece under the needle and this motion is achieved automatically by means of a work clamp, which is mounted for movement along two axes relative to the needle. Work clamp movement is controlled by a style or a feed cam, which is operatively linked to the clamp. Thread cutting is controlled by a second cam connected to the same shaft. In this manner, a limited amount of automatic operation is achieved.

The variety of patterns is limited by cam design and the gear ratio between the needle drive shaft and the camshaft, since each pattern must be completed within one rotation of the cam. The gear ratio is the relationship between the numbers of teeth on the two gears that are meshed. This necessitates replacement of the style cam for each change in pattern and in addition, if the number of stitches in the pattern changes, a new gear train must be installed. This effort may take anywhere from 2 to 8 hours by a skilled mechanic and results in a significant loss of production.

The fact is that mechanical cam follower driven lockstitch pattern tacker is no longer available from majority of sewing machine suppliers. Old machine models like PFAFF 3339-5/01 series and similar ones are still being used by the industry. The main disadvantage of these machines is their limited flexibility. The CAM needs to be replaced every time the shape of tacking requires a change. It results in 3 to 4 hours of machine downtime for each changeover.

Intermediate Level of Technology

In order to eliminate expensive changes resulting in a loss of production, there was a need to invent an automatic pattern tacker, which would be free of the restrictions of the style cam.

In order to convert the standard pattern tacker sewing machine to numerical control, the style and knife cams are removed from their shaft.

The knife cam is replaced by a new cam, which is operatively connected to its shaft through an electronically operated clutch.

Electronic pattern tacking machines have replaced the mechanical cam-follower controlled machines; eliminating machine downtime and opening an array of stitch options and flexibility under touch of a button”

The stepping motors are controlled by numerical control systems, which can be adopted to generate signals to cause movement of the workpiece clamp.

The computer controlled bartacking machine has seen radical changes in its evolution to be an easier-to-use machine.

Straight bartacking, square bartacking, cross tacking, crossed stitch tacking programs have been preset in the sewing machine and can be selected according to specification.

Advanced Level of Technology

There has been remarkable development in the pattern tacking machines from the basic level.

As compared with the conventional models, the basic performance has been dramatically improved.

For example instantaneous acceleration (deceleration) at the beginning (end) of sewing and high speed thread trimming have contributed to 24% to 35% shorter total cycle time as compared with that of the conventional machines.

In addition, sewing machine functions and patterns can be input through the operation panel. With large storage capacity, the machine supports embroidery patterns with large numbers of stitches.

Functions that are frequently used in programming works, such as normal sewing (linear sewing and spline sewing), point sewing, jumping, and thread trimming can be allocated to specific keys mounted on the operation panel. The use of these keys reduces the time required for data entry.

Functions that are frequently used in programming works, such as normal sewing (linear sewing and spline sewing), point sewing, jumping, and thread trimming can be allocated to specific keys mounted on the operation panel. The use of these keys reduces the time required for data entry.

The advanced level can sew free pattern, part sewing and reinforcement sewing with equal élan; attaching labels, emblems, attaching Velcro, shape tacking pockets and special Bartacking and large area cycle sewing (specially car air bags), are all possible in a single machine.