Today, the Indian garment industry is facing a fierce competition in global market, where price is order qualifier while transparency in system, excellent service, quality goods and timely delivery are order winners. To increase productivity, reduce costs, adapt to demand cycle and improve quality. One way is to have access to accurate and timely information on real time basis, which will help the decision maker to take quick and right decision. Playground is one such tool developed indigenously by Mathew V Thomas, Xcellent Technologies to address such needs.

Very few production houses in this industry are gathering the shop floor information and using it to take decisions to optimize the production process. At the earliest, they do it at the end of the day and that too the information is collected manually for the next day’s planning. They never know which operator will report for duty tomorrow and which will not. Usually, present Indian industry has a postmortem approach. It has been recommended that the manager/ supervisor should do the planning thrice a day for efficient output. For that, one should have accurate information of each machine on the floor.

Present Method

- One production head having reasonable educational background looks after the entire system.

- One or more supervisors per line are generally promoted from the operator level, not having even high school level education.

- One person keeps the data of the operators’ output and maintains the register. He reports to the supervisor and his CTC is Rs.4000/- month.

- Large size units are not organized and it becomes impossible for them to gather the sewing room production information manually and accurately.

So there is dire need to develop a system, which can reduce various production losses and help in timely execution of various jobs.

Production Losses in Garment Industry

Production loss in garment industry is mainly of two kinds :

1. Unavoidable losses

- Machine set up time.

- Material handling.

- Personnel fatigue time.

- Delay allowances like re-threading, bobbin change, needle change, etc.

2. Avoidable losses

- Response time for system balancing.

- Poor shop floor planning and balancing.

- Machine down time.

- Frequent machine breakdown.

- Inefficient Material handling.

- Late starts, early stops, low speed, extensive breaks.

[bleft]The system consists of several microcomputers and a host computer. Each sewing machine has one microcomputer installed at a convenient position for the operator’s use.[/bleft]

There is absolutely no doubt that increased machine uptime gives greater benefit. The greatest productivity loss is caused by idle machines and poor balancing. Unavoidable machine idle-time can be controlled and probably reduced.

But avoidable machine idle-time represents significant opportunity for productivity improvement through management action. If production managers or supervisors get timely high quality information, they can routinely assess performance and isolate the problems to increase productivity.

How Play Ground System Works

System Description

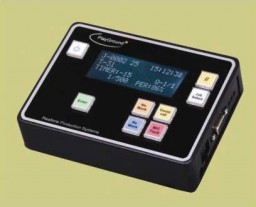

The system consists of several microcomputers and a host computer. Each sewing machine has one microcomputer installed at a convenient position for the operator’s use. Each microcomputer is connected to the host computer through a network. The microcomputer collects data on completion of each operation. The operation count can be taken automatically on thread trimming operation on a UBT machine and at stop motion on Buttonhole, Bartack machines, etc., without the intervention of the operator. For basic sewing machine, a switch is provided to enter the production count. If an operator does not finish the operation within the allowed time, the device will beep and intimation will go to the supervisor’s screen.

The device transmits data instantly to the server computer on all other status like NO-work, Machine Fault, Re-Work, Doubt and pause. The server analyses the data and generates various reports like production, WIP of each operation, efficiency of operator, status of job on hand, etc. These reports provide valuable and important information to the managers, supervisors and customers at any time. The device also provides cost effective logistics of material movement to meet a planned schedule. It also builds up the data bank for generating norms for standard sewing time of various processes.

Single Board Microcomputer

It is an 8-bit micro controller based system with a 128KB programmed memory to store. It has an eight-LED keyboard for inputting data manually. It has 20 characters, 4 line LCD display-to-display information like day’s production target, finished quantity, performance in % by the operator, name of the operation, job ID, operator ID, etc. Each operator can handle up to five types of work. It has also Real Time clock to get various event times.

The microcomputer requires separate DC power, which is fed through a separate bus system.

Auto Signal Capture

It is a contact type circuit, which senses the event of thread trimming on the sewing machine for production count. The number of thread trimming events can be selected to count as one pc finished e.g. on a buttonhole machine 9 thread trimmings count one pc as finished. This system does not require frequent intervention of operator to input data and thus eliminates wrong counts.

Networking

Movement of data is handled using latest bi-directional multi-drop Industrial data acquisition & communication protocol. Line PC is connected to several addressable microcomputer boards sharing cable. Thus it saves cable cost. Since it employs differential voltage transmission technique, data is transmitted efficiently.

Conclusion

The Play Ground system is a proven and most sophisticated technology available in the market today. It has tools and features that are designed to address the most important demand of the industry – Real Time Information on the production and resources. The system delivers an improvement of 15% – 20% higher efficiency through better management of the labour, WIP and time.

The hardware cost per machine is roughly INR 6500-7000 while the software cost depends on the number of licenses required. It is very cost effective compared with any other production system available.