India’s leading garment manufacturer Matrix Clothing has implemented WFX Smart Factory to digitally transform its manufacturing facilities and improve production floor visibility. Gurugram-based Matrix has been using WFX’s ERP (Enterprise Resource Planning) system since 2003 to manage operations and production. Matrix recently upgraded its systems with WFX’s Smart Factory shopfloor management solution.

WFX Smart Factory is a factory optimisation and production performance monitoring software from WFX – World Fashion Exchange. With over 600+ clients across 50+ countries, WFX is a market leader in developing modern, easy-to-use, comprehensive digital solutions such as WFX Cloud ERP, WFX Fashion PLM, WFX Virtual Showroom and WFX Smart Factory for the global fashion industry.

Founded in 1980, Matrix Clothing manufactures womenswear and menswear for big brands including NEXT, Ralph Lauren, Hugo Boss, Chico’s, Nautica, Debenhams, Esprit, Hollister, Napapijri and Timberland, among others. The group owns and operates five production facilities in Gurugram with a production capacity of over 6 million units.

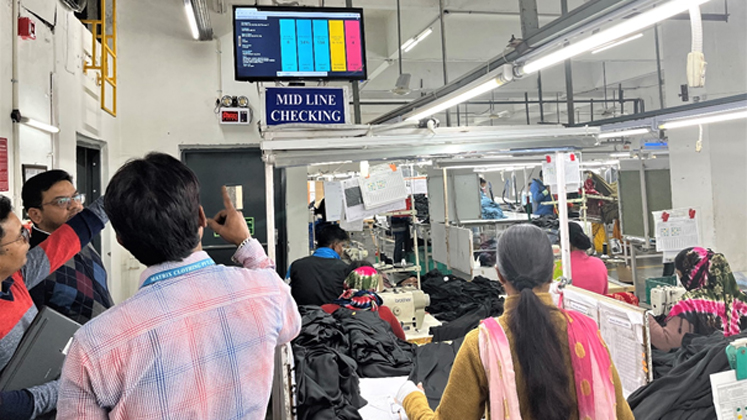

For its factories, Matrix wanted access to real-time production data with metrics such as hourly output and quality DHU (Defect per Hundred Units). After evaluating multiple solutions in the market, Matrix chose WFX’s Smart Factory because it allowed the company to integrate its entire workflow into one seamless shopfloor solution that makes it easier to take data-driven decisions. Matrix also liked WFX Smart Factory’s flexible nature to customise as per their specific needs.

Jeewan Joshi, Head of IT and Digitisation, Matrix Clothing elaborates, “Matrix has been using WFX ERP since 2003. And earlier we were using Zilingo to monitor factory performance, but it was standalone software and not integrated with our ERP. Due to this disconnect, our team had to update the daily production data again in ERP which was duplication of work and we wanted to eliminate this.”

Jeewan adds, “With WFX Smart Factory, we are able to access more features and functionalities—such as line-wise dashboard visualisation or management/factory dashboards and tablet-based real-time data capturing—which helps us make smarter, more informed decisions about how the shopfloor processes are moving in real-time with the opportunity to fix quality and any production bottlenecks instantly.”

WFX Smart Factory is helping Matrix Clothing achieve significant improvements in its production process:

- Better production floor visibility through real-time data access via desktop/laptop/mobile devices

- Faster response time for quality control issues with automated alerts

- Elimination of manual records which means better data accuracy and no manipulation in production data

- Improved scheduling accuracy with better visibility of work hours utilisation and KPIs

- No duplicity of work thanks to complete integration with WFX ERP and other systems

Jeewan says, “WFX Smart Factory has helped us create a seamless digital ecosystem across our entire production chain. Our teams are very happy using WFX Smart Factory, especially Line/QC Supervisors, Production Managers and Factory Heads, as they have live data visibility which helps them take immediate corrective action wherever required.”

To learn more about WFX’s digital solutions designed for the fashion industry, visit www.worldfashionexchange.com.