Apparel factories today have to majorly restructure the way they run their shopfloors, however only some of them ‘confess’ that they are doing it wrong. Quality issues, defects, scrap, rework, workarounds, waiting time, machine breakdown, downtime, no TnA, and other forms of wastes hugely impact performance and the bottomline of the factory. If they know the problems, then the question is why they are not being fixed? The problem is that the scale and size of these wastes and indicators of its root causes are often not available to the people who are best placed on the production shopfloors to act. It is as if the factory performance is ‘hidden’ from them, so they are unable to make the necessary improvements.

Therefore, exposing this hidden factory performance is the first step towards improving the operational performance and profitability of any sewing factory. The same provides an opportunity to not only reduce manufacturing cost but also gain untapped capacity. There are technologies available now to help factories discover the ‘hidden parameters’ by adopting digital tools and can see massive changes in their factory operations…

Banswara Syntex (Daman & Surat) improves Operational Performance Measurement significantly using STITCH MES…

A prominent vertically integrated textile and apparel company, specialising in the production of yarn, fabric and readymade garments, relooked at its processes in early 2021 and felt the need for adopting manufacturing suite solutions to improve the manufacturing operations in support of their goal to become a smart factory.

The garmenting division of the company had long been grappling with challenges such as errors caused by manual processes, paper-based data capturing, fragmented data obtained from multiple sources; and quality defects rates that were never monitored. These collectively led to factory inefficiencies and margins were eaten away by these inefficiencies.

Read more – A look inside HUGO BOSS Smart Factory

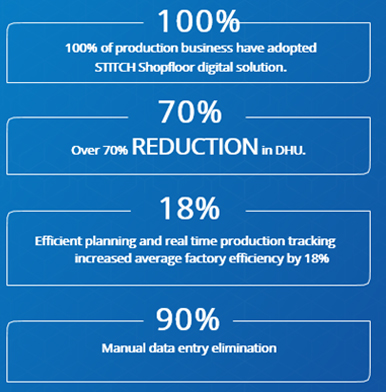

According to the company, it went for a complete Shopfloor Digital Transformation of its 65 production lines in 2 factories in 2021, using STITCH MES that worked with them as a digital assistant which constantly analyses production data, offering their operators and managers alerts and smart recommendations in real-time. This is an important step to reach the competitive edge the company needs and address market challenges during COVID-19 and beyond.

“We’re able to foresee problems now, instead of them just popping up all the time….I’ve seen benefits of astronomical proportions just in terms of a reduction of Defects, Downtime and Cost,” informed Rahul Bhaduria, Operation Head of Banswara Syntex.

“Banswara Syntex’s adoption of STITCH manufacturing suite software has also increased their cut-to-ship ratio by around 10 per cent to over 95 per cent now, while reducing the factory’s reliance on manual processes to improve their real-time visibility and production volumes,” told Durga Charan Das, Co-founder, STITCH MES to Team Apparel Resources.

Laguna Clothing (Bengaluru) collaborates with Jaza Software to enhance quality inspection system and line balancing…

Laguna Clothing, a shirt manufacturing bigwig located in Bengaluru and a subsidiary of CIEL Textile group, has made great strides in this direction… However, even if the company is as big as a producer of over 6 million shirts a year, it still had faced some troubles especially in quality department wherein tracking of inspection at operation and operator level was a cumbersome process and visibility wasn’t there. There were unwanted halts in Predictive Quality Management System; line balancing; and data transparency. Therefore, Laguna collaborated with Bengaluru-based tech company Jaza Software and deployed its flagship product OptaFloor on its production floors.

Read more –Framework for evolving from Traditional to Smart Factory

Jaza team worked closely with Laguna’s quality team to understand requirements and equipped them with real-time information from the quality audits and used the information to eliminate the bottlenecks/defects at source. Now the company reports that its quality team is equipped to handle the issues proactively by using historical data and advanced features of ‘Roaming QC’ feature.

Commenting on this digital transformation, Manish Sinha, Country Head Operation at Laguna Clothing, mentioned, “We have set a vision to make our factories smarter to give smart service to our customers. We want to have smart device in every employee’s hand including operators to have complete data transparency and single portal for real-time collaboration among the departments. We are not looking at only internal digitalisation but also want to provide a unified app to our customers where they can track their orders in a click.”

With OptaFloor from Jaza, Laguna has seen an increase in its efficiency by around 13 per cent, productivity by 18 per cent and reduced defect rate substantially to below 1 per cent now. The company further reports that quality is just one but important aspect of using these tools, but producing world-class premium shirts requires line balancing too with team of skilled workforce, and with advanced feature of line balancing, supervisors now get alert about the skilled operators’ availability and help them to take counter steps without losing the production in first hour. Supervisors have complete visibility of the lines and they know WIP on each workstation that help them in line balancing in real time to avoid bottlenecks.

Md. Jawed Akhtar, CEO & Co-founder, Jaza Software, shared, “Today companies need to be agile, resilient, connected, and collaborative to survive in the long run. To achieve this, mere digitisation of shopfloor data is not enough. This requires holistic optimisation of the entire manufacturing value chain and this is what we are committed to doing with Laguna Clothing.”

Wiintrack Exports (Tirupur) reduces DHU rate and improves visibility into line-wise KPI data using Zilingo Factory…

Founded in 1996, Wiintrack Exports is a reputed kidswear manufacturer (both knitted and woven) that’s located in Tirupur, India. They are an integrated unit comprising functions from spinning to packaging and warehousing. The company has realised that the lack of visibility on the shopfloor made it difficult to analyse if the departments were being overfed or starved; the high rejection rate led to order shortages and increased wastage in the form of rejected stock; and the overall inefficiency of production operations led to an increase in DHU.

Read more – Future factory of apparel manufacturing needs to be smart, agile and result-oriented

To go smarter, Wiintrack joined hands with Zilingo Factory’s production software that helped it get stronger analytics and see greater improvements across multiple operations. The partnership resulted in providing Wiintrack three solutions: Tag Generation; Cut Bank In/Out; and Sewing Endline.

Installation of the Tag Station helped Wiintrack identify a bundle, track garment movement between stations, and aggregate as per the different parameters. It helped identify bundles that needed to be moved to another department or are ready to be stitched together.

Further, the tracking station was installed to make sure that no sewing line was either under or overfed. It also helped maintain optimum WIP in the cut supermarket and track the movement of bundles until they moved to the sewing store.

Sewing endline enabled QC manager to identify the common defect points and also categorise them on the basis of minor, major and critical issues. The defects were further categorised by operation and style to give more accurate information about areas of improvement.

Zilingo reports that Zilingo Factory provided stakeholders of Wiintrack Exports with access to real-time data and enabled them to take quick corrective actions. It empowered them to take strategic decisions based on insights derived from detailed analytics reports and efficiently manage order fulfillment within the lead time.

As a result, Wiintrack Exports was able to increase efficiency to 76 per cent from 72 per cent. The software captured real-time data and provided end-to-end floor visibility. By tracking defect locations, the factory has been able to identify and reduce their DHU rate by 80 per cent, which has resulted in an increase in overall production efficiency.

“We were facing a lot of challenges with identifying the garment’s movement inside the factory. With Zilingo Factory in place, we have clearly been able to reduce this unwanted movement of garments. We have also increased our efficiency and reduced our DHU rate from 5 per cent to under 2 per cent,” commented Prithvi Raj, CEO, Wiintrack Exports.

Digital transformation of factories will continue in India…

The average efficiency of all the labour-intensive manufacturing industries, including apparel, is below 50 per cent and the COVID-19 pandemic has disrupted the manufacturing supply chain even further. There is now an increased pressure to reduce the production cost and lead time that demands increased operational efficiency, more flexibility, and better quality. With the increased focus on sustainability and transparency, the brands are looking for suppliers/partners that are ready to meet the changing needs. The factories in India have started realising the same and they are gradually, yet strongly, moving to digitalisation on their production floor to help track the operations. Apart from Banswara Syntex, Laguna Clothing, Wiintrack Exports, a lot of other factories such as RK Industries, Zedex Clothing, Avanti Overseas, Pratibha Syntex, Carnation World and Panorama Apparels among many others have joined the bandwagon of converting their factories into smart.

Read more – Smart factories are all talks!