TUKATECH, a leading CAD/CAM and product development solution provider, began work on new software, the e-fit Simulator by TUKA in 2004, with the goal to create virtual garment on the computer from actual patterns. The virtual garment not only showcases how the garment fit on a virtual dummy while static, but also highlight the shortcomings while it is in motion, such as walking, bending, etc. This motion can also be customized for a particular garment application. Talking about the software, founder of TukaTech Ram Sareen said, “We wanted this ‘digital garment’ to be portable, so that people all over the world could view the garment. We also wanted it to be easy, so that patternmakers of all levels could use it as part of their development process.”

TUKATECH, a leading CAD/CAM and product development solution provider, began work on new software, the e-fit Simulator by TUKA in 2004, with the goal to create virtual garment on the computer from actual patterns. The virtual garment not only showcases how the garment fit on a virtual dummy while static, but also highlight the shortcomings while it is in motion, such as walking, bending, etc. This motion can also be customized for a particular garment application. Talking about the software, founder of TukaTech Ram Sareen said, “We wanted this ‘digital garment’ to be portable, so that people all over the world could view the garment. We also wanted it to be easy, so that patternmakers of all levels could use it as part of their development process.”

Can you imagine making the whole car from a sketch and then see how everything looks? For that matter can you imagine making a tall office building and then try to change location of elevators, windows or doors? Of course not; 3D modelling is extensively used to develop almost all products these days and ‘e’ plays a major role. The truth is that, if we made cars or buildings the way we make apparel, it would cost heaven. However, in the Apparel Industry, we physically make the entire garment (first sample), and then see how it looks, modify by making another sample to see the changed look and then try to fit the garment while making yet another sample.

In the process, the average number of samples before a product is released is three and it takes approximately six weeks for approvals. Often the iteration extends to 4/5 times depending on various factors like raw material, style complexity, supplier capability. In this fast moving world, faster and fastest is still not fast enough. Although we all recognize the need to get faster approvals for samples to get faster production, we continue to oil and grease the same old machinery hoping to make it go faster.

But things are set to change … The buzz in fashion technology today is e-fitting, also called virtual prototyping, or virtual sample making. Most people know it has something to do with 3D and computers, but what exactly is this process, and how does it work? How will it help the fashion industry? Who can really implement this technology?

Let’s Review Some Facts:

- Average markdown in retail is 31%, (too big a number to ignore)

- Average labour cost from exporting countries is between 8% and 12%, (too small a number to panic, even if I save 25% labour, it will be 2% to 3% of total selling price, can we use them for other processes)

- Average cost of importing goods is 8% for QC, commissions, travel, sourcing executives, (I could have made it in the country where we sell for almost the same cost but faster, lowering the risk of markdown)

- Average cycle time from concept to consumer is 150 days, (big problem, need to address)

- Average concept to Tech Packs to approval time is 90 days. (It was faster, but not cheaper to do it in-house)

- Average cost of sample in USA is running at $ 400 to $ 1200 depending upon garment and label. The buyer, on an average spends up to $ 1200 to arrange for a fit model, the designers and technical experts to give a fit approval. (We really need that exporter in cheaper labour countries now to help)

- The number of units per style is down and will continue to decrease; this will add workload to develop more new styles to maintain volume of business. (This will be the right time to panic).

The reality is that every label and brand has only one thing constant and that is his or her fit. In fact, consumers are willing to pay extra for the perfect fit and often justify paying higher price for Brands that can provide the combination of fit and fashion creating brand loyalties. With fitting so critical to success, the concept of e-fitting was born.

The reality is that every label and brand has only one thing constant and that is his or her fit. In fact, consumers are willing to pay extra for the perfect fit and often justify paying higher price for Brands that can provide the combination of fit and fashion creating brand loyalties. With fitting so critical to success, the concept of e-fitting was born.

What Does e-fitting Mean?

E-fitting stands for electronic fitting, which is a way of saying, “testing fit on the computer”. Just as you have a fit session for a garment in real life, with a fit model and a design team, e-fit Simulator takes digital patterns and turns the pattern pieces into “virtual cloth” that can be sewn in the computer and tested on a 3D fit model, right in the software, showing you exactly how the garment is going to look before you sew a single real sample.

This means that you can make design decisions by visualizing the garment digitally – no need to buy fabric, stop work on the project until the Fed-Ex representative arrives, or wait your turn in the sample room line before seeing how your creation looks.

Another advantage of e-fit is getting excellent and accurate drapability of different types of fabrics

Most industries these days use computers to test their products before they produce them in real life. Why not the garment industry? Rather than producing a physical sample before we test a garment’s look and fit, e-fitting means we can see our garment on the computer first, to detect and correct problems early in the development process, rather than weeks down the line.

As a patternmaker, it is often difficult to understand exactly what needs to be done to correct a pattern until you have seen it sewn and draped on a mannequin or a person. E-fitting allows you to create patterns efficiently and accurately, which ultimately reduces the time spent making samples and getting approvals.

How Can It Help?

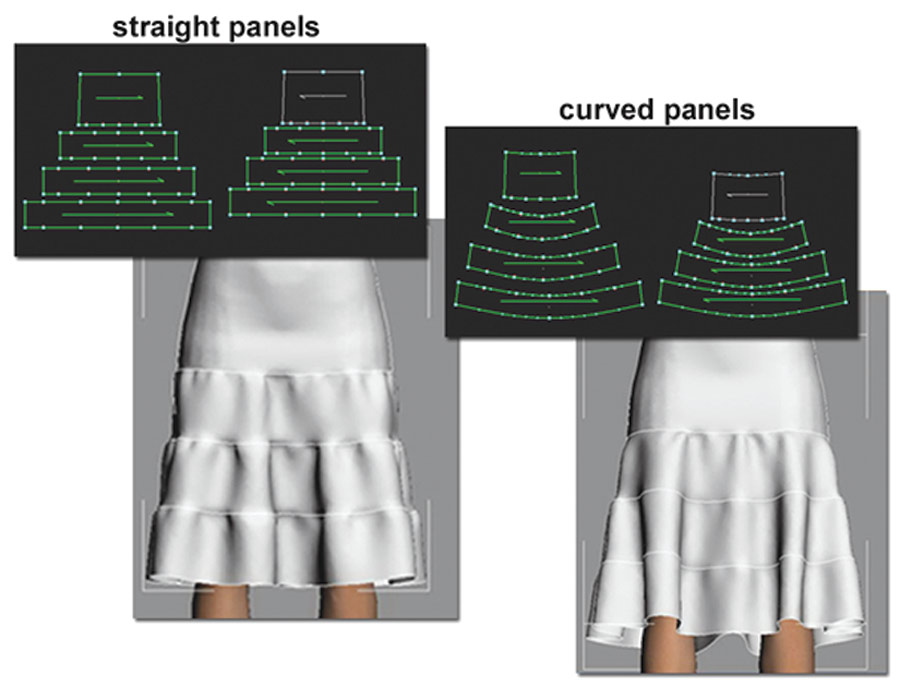

Consider this real-life example of a common problem in garment exporting: A buyer sends a vendor a dress pattern along with a sketch of what the garment should look like. The vendor is told that they must use this pattern block, because the fit has been pre-approved for this size. However, the vendor, upon viewing the pattern, suspects that the garment will not drape the way it looks in the sketch. The sketch has length-wise conical folds down the dress, but the pattern has straight pattern pieces, without any curve in them – straight pattern pieces tend to create scattered folds, not conical folds. What to do?

At this point, the vendor has two options: Sew a sample and let it come back rejected, because the conical folds in the sketch aren’t visible in the garment, or send two samples, one using the original pattern and one using the suggested pattern, to show the difference. In either case, everything from pattern development to costing has to wait until the buyer sees both samples, and chooses one of them – a process that could take 1 to 2 weeks.

With e-fit Simulator, the vendor doesn’t have to guess, or wait for both samples to be created before finding out whether his or her suspicions are correct. The pattern can be imported and draped in the software, and quickly we can see which pattern produces the correct result.

Then, a movie and screenshots can be sent along with the digital patterns back to the buyer via e-mail. Within a day or two the decision is made, and a costly pattern error is detected and corrected before a larger, more time-consuming problem occurs.

As lead times get shorter, and more and more seasons get added to the retail cycle, the industry must adapt and adopt new ways of approving and quality-checking garments quickly, across the global marketplace.

3D simulation is quickly becoming a fact of life in the Apparel Industry today.

Why didn’t 3D Work? Many Suppliers have it and had it for Years!

Simple, you can write code for software but understanding what to write needs industry experience and product application knowledge. Several CAD suppliers got in the market for 3D products but without real focus, it sounded good, looked good, and had many opportunities in Internet retail, virtual try-on in stores. 3D solutions were developed but did not sell.

The biggest flaw in most of the 3D products is the way models are being created… created from measurements. There are measurements and there is shape, there is no way to replicate 3-dimensional shape. Shape and measurements are so important to be consistent that most of the designers prefer to work with same model at the same time every day so they can have consistent measurements at every crucial fitting area.

Most designers calibrate their models by measuring them periodically so to make sure there are no measurement changes. The industry which runs on such stringent guideline cannot take the risk by allowing CAD operator to have ability to Morph/change or even develop a computer fit model, especially when operators try to make the model bigger or smaller by just inserting measurement values. Imagine just changing the waist and human body just grows equally only in one area.

Designers need to see how it fits while a model bends, walks, sits, etc. Earlier 3D CAD software showed static picture, may be with different poses but no real time motion. Without this live feedback, there was no confidence from design community.

90% of the CAD users make patterns by hand, on paper. Most of the CAD users digitize, grade and make markers on CAD. Especially in exporting countries where we are trying to push product development, 3D solutions will never work until patterns are made digitally and tested on 3D and that too in ‘motion’ depicting all movements.