Footwear is the engine of growth for the entire Leather Industry in India, which is the second largest global producer of footwear after China. The de-licensing and de-reservation of the entire leather industries has paved the way for expansion on modern lines with state-of-the-art machinery and equipment.

India currently manufactures 909 million pairs of leather footwear and 1056 million pairs of non-leather ones. The recently concluded IILF organized by India Trade Promotion Organization (ITPO) was a witness to this fact. The fair attracted a large number of participants and equally enthusiastic visitors. Team StitchWorld evaluates some of the technologies presented at the fair.

The assembly of shoe uppers is a labour-intensive activity requiring highly developed manipulative and supervisory skills to ensure economical production of adequate quality. A typical manufacturing unit might at any instant have in process –say 20-40 or more shoe styles, each one comprising left and right, each with ten sizes and perhaps as many as twenty components in the upper alone. The rising labour wage component and increasing demand on quality, clearly indicate the use of automation in machinery. Moreover, automation becomes all the more important in these times of slowdown as even the most difficult and tricky operations can be carried out with ease at high speeds, thereby becoming cost-effective.

Strobel’s 141-23EV, a single thread overseaming machine with gathering device is used for sewing insoles to shoe uppers. Represented in India by HCA.

In relation to the conventional lasting-method the Strobel method saves quite a lot of material. With this machine, leather or textiles up to a thickness of 7 mm can be sewn. The gathering device helps to sew in fullness of the upper. Different feed and front cups (Optional equipment) enable the machine to manufacture children shoes or very delicate material. Even kits for string lasting with strings up to 1.7 mm or up to 2.5 mm diameter or for California type shoes and thread lubricator are offered by the company. The machine operates at a speed of 2300 RPM.

Highlead has two very popular models GC24518-1 – GC24518-2 post-bed series and GC24699 high post bed lock stitch Machines. Represented in India by HCA.

The GC24518-1 & 2 series adopts top and bottom feed by needle bar and feed dog. The thread is taken up by the sliding bar and is caught by the vertical rotating hook to produce double lockstitch. It uses cog belt for arm shaft and hook shaft driving. The post bed of 178 mm offers flexible and free working space, fitness for sewing several layers of different material with beautiful stitches, preventing any displacement between the layers.

With a maximum sewing speed of 2500 RPM and a stitch length of 0-5 mm, it has a needle bar stroke of 33.4 mm. The presser foot lift by hand is 7 mm and by knee is 10 mm. The auto-lubricated machine has needle size of DP X 5 ranging from 11” to 4”, a needle gauge of 2.4 mm with a vertical rotating hook.

Highlead’s another model GC24699 is a serial product of the company’s high post-bed lockstitch sewing machines. The machine is ideal for boots, handbags, hats, periwigs, etc. It is designed with compound feeding mechanism for stitching multi-layer materials, high post-bed and special needle plate for stitching surfaces with small radius. The special high post-bed with a height of 450 mm can be tilted toward the machine operators to put material to be sewn onto or remove it from the high post-bed.

The machine, with a vertical rotating hook, runs with a maximum sewing speed of 1600 RPM. It has a 36 mm needle bar stroke; the stitch length varies from 0 to 7 mm. The presser foot lift by hand is 8 mm and by knee is 15 mm, with presser foot alteration between 3 mm and 5 mm. The semi-automatic lubrication machine has a 370 W clutch motor with a running capacity of 1400 RPM.

Advanced Vision Controlled Stitching Machine by Orissol, enables complete automation of stitching process. Represented in India by Star International.

Orissol, SEE.N.SEW-5035 is a computer controlled stitching machine for shoes and leather goods production. The machine is meant for joining and sewing applications for athletic, causal, safety and dress shoes for men, ladies and children. All types of decorative and re-enforcement stitching can be done on shoes, bags, leather goods, technical articles, webbings, etc. The complete Orissol system enables the automation of the complete stitching process from the design of the shoe upper to the closing of a three dimensional upper. Shoe geometry may be either imported from a shoe design system or directly digitized into the company’s ‘SewCAD’ software where stitch and milling programmes are produced. SewCAD is compatible with most leading footwear CAD systems. The graded geometry is imported into the SewCAD for easy and rapid preparation of stitch programmes. While doing manual designing, SewCAD helps in computerizing the designs and preparing them for automated sewing.

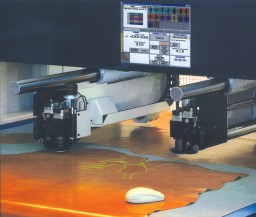

Italian Cutting Solution specialist ComeltZ offers CMM44CN

CMM44CN is a knife cutting machine for leather, and synthetic materials. The knife cutting technology eliminates the cost of cutting dies while taking the advantage of direct connection to the CAD system to immediately begin production. It cuts the material after direct transfer of patterns from any CAD system where the file is in SXF or HPGL exchange format. The two cutting heads in a compact area served by a powerful local vacuum system and two cutting heads share the work of maximum optimization of operations. The rear table allows independent removal of cut pieces. The machine allows continuous nesting without pause or change of workplace; thus, the operator maintains full focus on nesting the pieces on the skins carried by the conveyor belt. Due to the coordination of the conveyor belt, skins as wide as 1.5 m and unlimited length can be fed, positioned and cut in sequence under full control of the operator. For synthetic materials, in one or more layers, the automatic nesting function can perform fast piece positioning. Therefore, the cutting heads are well exploited and the operator is freed from nesting activities. So, he can fully focus on the collection of cut pieces.

Romans CAD 2D, Romans CAD 3D Bag and Contour Lumiere 2 from Lectra speeds up designing and cutting room activities specific to the Leather Industry.

Lectra’s RomansCAD Software Data Management is a unique comprehensive PDM, 100% dedicated to the Footwear Industry. It speeds up the collection creation process by enabling real-time sharing of all product development information – including technical documents or highly advanced synthesized images – between decision-makers, designers, suppliers and customers. Due to new 3D imaging and electronic transmission capabilities, the time needed to develop a new collection can be reduced by more than half. Speaking about Romans CAD, Phillipe Albert, Business Developer Footwear and Leather, Lectra explains, “With traditional processes, a company with multiple sites needs 4 to 6 months of time to develop a model from the first sketch to design approval. With the tools Lectra is offering, the time needed to develop and approve a virtual product and produce the only physical prototype necessary for final validation is significantly reduced to 4 to 6 weeks. Lectra’s RomansCAD Software 2D has been improved to suit the specific work of the leather goods industry more closely. It integrates pattern design functionalities such as interactive management of work by symmetry, a baluster function, as well as management of lengths and quotations. RomansCAD Software 3D Bag enables leather goods companies to simulate a model in 3D easily and quickly, using the organization given by the whole software range. With RomansCAD Software, the creation and execution of production orders, operator and machine parameters, interactive marker-making by video projection and automatic marker-making are managed and totally integrated into the company’s technical data management. Lectra’s Contour Lumiere 2 software includes high-performance tools for nesting and cutting prototypes, samples, short runs, extreme sizes, repairs and production. The software allows two hides to be laid out simultaneously. One hide is marked while the other is cut. Contour Lumiere 2 can be installed “on line” with the nesting devices as part of the cutter or “off line” when necessary to nest the hides on a separate station to optimize the cutting time and to manually position some pieces.