Fashion businesses, including manufacturing, across the world, are rapidly moving towards digital transformation which is what makes technologies like ‘digital twin’ strongly shift from concept to reality. IBM defines digital twin as “a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.” Simply put, digital twin is an exact virtual replica of a physical process/product/factory or any real-world item.

Now one may think how different is a digital twin from a digital avatar? A digital/online avatar doesn’t act as a hub of information, does not collect data and does not run simulations to make accurate predictions. On the other hand, a digital twin, in the manufacturing context, runs a physical process in virtual space to help humans understand the possible challenges in the production processes.

In the fashion manufacturing industry, the digital twin of a given garment can contain every information from the design origin and fabrics used to create it, to production process detailing. The most visible advantage of using digital twin in the manufacturing industry is fabric wastage reduction, while there are numerous other intangible benefits too such as enhanced speed to market, efficiency improvement etc.

Fabric gets wasted majorly in two processes in an apparel factory – pre-production and production. It’s estimated that fabric loss is around 10-15 per cent during cutting process, while inefficiencies on the sewing floor (waste during sewing process, rework/rejection etc.) just add the number to the loss. Most of the factories generally do not have any idea about how much fabric wastage they generate, let alone the ways to reduce it! Digital Twin can help factories reduce this wastage along with many other benefits, as it helps create an exact copy of physical operations in real-time.

Today, there are precisely two areas in an apparel manufacturing unit where digital twin can effectively be used – (1) Digital Twin through 3D in product development processes; and 2) Digital Twin through AR/VR in production processes wherein production run is simulated in virtual space to understand production’s problem, wastage and efficiency issue.

Digital Twin in product development at fabric sourcing level – true advocate of sustainability

The fashion industry is one of the largest contributors to pollution and waste in the world. The fashion industry creates more than 100 billion clothing items in a year, and as per BBC Earth, 80 per cent of discarded clothes end up in landfill within 12 months. And all these items are manufactured using 1,000 different types of chemicals, making the recycling process challenging and complex. The bottom line is that the planet is paying a high price for cheap apparel. The rise of e-commerce has made access to fashion and apparel far wider around the world. The consumption of apparel has increased enormously, and with increased consumption comes huge growth in the quantity of clothing that gets discarded.

Traditional sample making is NOT sustainable at all. One of the reasons for waste and excess emissions in the fashion industry is investments in physical sample-making. Over 30 per cent of the material is wasted during the sample-making process. On an average, for a single piece of clothing, there are around seven stages of sample making. When a prototype sample is finally made, manufacturers usually have to create the samples for their buyers in different colours, patterns and fabrics. Most of these physical samples go directly from the factory floor to storage and ultimately to landfill.

The fashion manufacturing industry is gradually adopting 3D virtual sampling in its product development process and there are established players in the market with their 3D technologies such as TUKATECH, LECTRA, CLO3D, BROWZWEAR, and OPTITEX among many others. However, unlike before, the technology companies have now created 3D digital fabric/material swatches as well, eliminating the need for using physical fabrics in sampling to minimum.

In an exclusive conversation with Team Apparel Resources (AR), Victor Chao, CEO, Frontier – a Taiwan-based 3D material innovator, said, “On the savings side, using 3D materials to design and prototype speeds up the sampling process from 3 months to 3 days (30x), increasing speed to market. Fashion businesses can cut costs associated with sampling by 50 per cent or more when implementing digital prototyping, which includes shipping, sample yardage, Salesman samples (SMS) and re-approvals.”

A simple, ordinary scanner or a multi-functional office printer (which is probably already in the office, to begin with) is all that’s needed to get the fabric library digitised and ready for use. There’s no additional software to install and learn, so the mills/factories can get their digital swatch libraries up and running promptly.

However, time is only saved in the sample design and making stage. The industry still needs more than three months for fabric sourcing and narrowing down the material into the prototype stage, which is a consequence of the industry’s inefficiency in scaling up the material digitisation process. The current way is to ship the fabric swatch to a specific scanning centre or to invest in a dedicated lightbox and fabric kit to get the metadata layers and physical properties. It is challenging to achieve digitalisation on a large scale with the amount of money invested and staff training. And this is where Artificial Intelligence comes to support the industry.

“Thanks to AI technology, we can effortlessly digitise the fabrics at the sourcing stage. The supply chain only needs to use a standard home or office scanner to scan the physical fabric swatch, and the AI engine will generate its texture maps and physical properties. The result will be tens of thousands of Fabric Digital Twins to save time from the starting point. From inspiration to sourcing and design can be shortened from 6 months to 7 days. The brand designers benefit from scalable results from AI at the sourcing stage instead of waiting to receive physical samples from all over the world,” averred Victor.

Another 3D material company is South Korea-based SwatchOn that’s a member of the CFDA Materials Hub. SwatchOn’s wholesale fabric offering of 200,000 SKUs has made its VMOD 3D library a global resource for independent labels, mid-size brands and the apparel manufacturers in the world. In 2019, well before the pandemic, SwatchOn created a digital twin of its first fabric. VMOD uses the latest technology from Vizoo to achieve high-resolution surface scanning, capturing seamless PBR (Physically Based Rendering) texture maps. The technology has also seen investment from CLO3D, signifying the need for using more of 3D materials in product development.

Most of the new-age AI engines used in the digital material twin generation are said to be over 90 per cent accurate, making digital twin a favourable technology for large-scale adoption in the garment industry.

Industry’s comments on Digital Twin’s use in apparel manufacturing

“We feel 3D design is the present and future. 3D sample reduces enormous cost, time consumption and increases speed to market. We, at EPIC Group, are also using predictive analytics so that we can help our customers reduce inventories and tell them in advance what would be the trend next season! We are not just simply manufacturing the product but providing full-service solution by understanding data end-to-end and speeding up the supply chain. This is greatly helping up reduce inventories, markdown and input costs for our customers,” Roger Guy Young, Chief Strategy Officer, EPIC Group.

“We have started to adopt digital sampling technologies since 2017 and it has been gradually accepted by our customers. This demonstrates our sustainability commitment in redefining how we manufacture jeans. Recently, the trend of digital twin in sampling is particularly accelerated during the times of social distancing. 80 per cent of our self-developed products are using virtual samples in the product development stage as of 2021, while we aim to take it to 90 per cent,” Miles Lam, AGM (Product Development) of Crystal Denim – a sister concern of the world’s leading garment manufacturing group Crystal International.

“Just like apparel factories are creating ‘Digital Samples’ of their products, we came up with the same in denim fabric, 3D rendering of which is 99.99 per cent close to our physical samples. We understood that physical samples will not be in demand from now onwards due to a lot of cost and time-related reasons, so we created Digital Twin of our denim fabrics. All our customers are embracing the newly developed digital samples,” Srihari Balakrishnan, Managing Director, KG Fabriks Ltd.

Digital Twin on apparel production floor is massively underutilised!

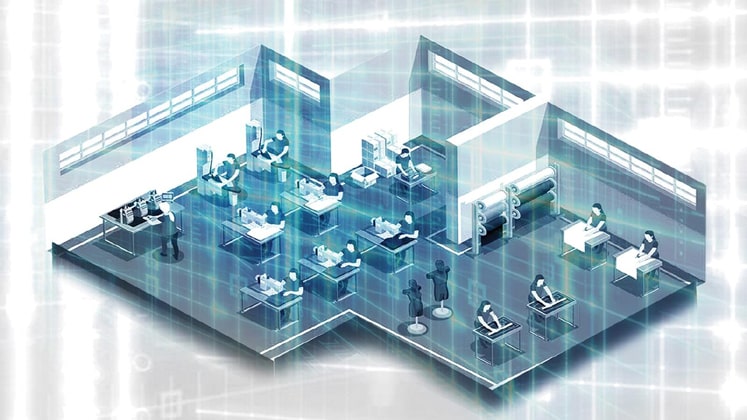

A shopfloor digital twin requires a model of the factory as it exists, or a simulation of how it wants to exist, and data from the factory floor for understanding and improving processes. Typically, this data may not be readily available from the factory floor because of limited IT resources or infrastructure. The Industrial Internet of Things (IIoT) and cloud computing make this data more readily available than it has traditionally been and reduce the infrastructure necessary for a factory floor digital twin.

However, the understanding of usage of Digital Twin on production floor is limited. In the words of Joachim Hensch, Founder of Joachim Hensch Consulting – shopfloor nowadays is a digital desert! Although some apparel factories have started to trace and track pieces on shopfloor through RFID trackers, barcode scanners, but the industry is far away from talking digital twins on shopfloors. Reason? Most of the decision makers are from an era which would always work on reducing the man-machine ratio and simply follow the analog business principle. And the problem is that they don’t understand what to invest into as they don’t feel the process and its gaps, whereas the ones who feel it, don’t have decision making power.

Digital twin in apparel factory can help make profits significantly, provided the factory goes about it step-by-step. The industry should understand they just need not do heavy investments that are not even factory-friendly but they should invest in those innovations which a factory really needs to pace up with standards and make it cost-competitive in true sense.

“In an unbelievable span of different ages of industrialisation and technological adaptation, some factory owners don’t realise that digital twin or digital part of their factory needs the same attention and the same care as the physical twin as, in the physical factory, they rarely disconnect cutting with sewing, sewing with finishing, and packaging with warehouse! But after investments into digitalisation, they screw it up,” mentioned Joachim.

Creating a digital twin of the shopfloor means creating a virtual copy of all the manufacturing equipment, operators and even operations. Integrating the data of product digital twin, it is then possible to simulate the entire factory and the chances of error can be eliminated even before a garment is actually produced. Different combinations of machines, operators and assembly lines can be analysed to compare throughput as well as the ergonomic risk between manual and automated operations.

- Digital Twin of operators’ soft training

One of the areas where Digital Twin can be applied is operators’ soft training, quality process integration, product information and machine information using AR and VR concepts. For example, a factory, using AR tablet, helps operators capture the machine image. Once the image is captured, the tablet can use this virtual image and play a video process of the maintenance and lubrication of this machine, so that the operator can understand the whole process by himself, over and over again. This is simply digital twin of a physical process (maintenance and lubrication).

- Digital Twin for product development training

Another training area can be enhancing and digitalising the Product Development Training process through VR. The screen of VR tablet can show a list of products and list of operations in each garment product. A video – made using Digital Twin – can be played for each of the operations for operators to understand the critical points of a particular garment product. This way they can know potential quality defects in advance and take care of it when they work on garments.

- Digital Twin for monitoring of product usage

Digital Twin can further be used to monitor product usage on the shopfloor. A finished product’s digital twin can be monitored in real-time, as the product digital twin continually records the product usage status data, uses environment data, operating parameters, etc. Secondly, the virtual model can confirm about the probable effects of the different environmental parameters so that they can be controlled. Furthermore, based on the real-time data from physical products and historical data, the product digital twin is able to accurately predict the product’s remaining life, breakdown chances, etc.

Benefits of Digital Twin for Manufacturing Companies

- Reduces product defects: Virtual representation of the product can undergo a number of conditions and based on the results, necessary adjustments can be done that can be mapped to the physical product.

- Reduces production costs: Mapping digital shopfloor for capacity planning and possible downtime can cut down on the production costs.

- Real-time monitoring: A user can monitor the working of the product or process in real time sitting anywhere in the world and can even change the reason of the defect.

- Shorten time to market: A well-mapped product and production processes will perform efficiently in the real world, thus saving time and money in simulation, testing and analysis.

- Extend the life of equipment and assets: Digital twin allows companies to have a complete digital footprint of their products, thus eliminating any chances of wear and tear, and extending their life.

Digital Twin of sewing operators’ skill mapping – NIFT Delhi takes a step forward

The use of digital twin technology for sewing operators is a sort of new concept for the industry but this can help factories understand operators’ skill strengths and weaknesses in terms of their skill attributes which will enable rational job allocation to improve productivity and quality. India’s NIFT (National Institute of Fashion Technology) is probably the first institute across the world which has a patented technology for this purpose.

According to Prabir Jana, Professor, NIFT Delhi, this digitalisation is necessary for sewing operators and unfortunately, it’s not found in the industry. “The factories generally prepare just an operation matrix, which tells us who can perform what operation. However, two different operations may require similar skills. We have revolutionised this process with a system which can actually measure any operator’s generic skills objectively, create digital twin of the operator and facilitate fair wage, transparency and job portability. This has been a dream of many high street retailers as they talk about fare wage,” commented Prabir.

When it comes to middle management and top management, their resume and communication skills tell companies about them if they switch jobs. However, the sewing operators don’t have anything to prove their expertise on sewing machines. But now, with NIFT’s system, if operators are shifting job from one company to another company, they don’t need to prove themselves as the digital certificate tells everything about their skills. “This is really helpful in operator portability and in making factories smart and future-ready,” informed Prabir.