Lay planning, cut planning, lay lot planning, or cut order planning are the most crucial activities in a cutting room which decide how an order should be cut. To begin with, how many and which garment sizes should be there in the marker, what type of marker combination should be used and how many layers of fabric should be laid out in one lay, are all critical issues that need to be considered. Once all these parameters are determined, it is the endeavour of the cutting room to complete the cutting work in the quickest time by consuming bare minimum fabric, at least labour costs and by incurring minimum total cost.

Team SW reviews the common features of five Cut Order Planning Software solutions available to the industry to optimize cutting operations…

COP is a powerful integrated tool to optimize fabric utilization, cutting room process, timing and manpower, rapidly creating schedules and adapts them in minutes in daily production requirements, saving on time by up to 15%

In spite of several complicated and complex calculations of how many layers in a lay and what marker combination is required, the optimal solution is often underestimated and accomplished by the cutting master who uses nothing but one register wherein he records the spread and cut quantity sequentially and follows reducing balance techniques. In reality, the cutting master may have probably achieved one of the correct solutions but in reality it may not be the most economical or the quickest one. With tighter profit margins, manufacturers should explore every possible opportunity and realize the untapped potential of optimizing cut order planning.

Once considered a very scientific process and one of the most complicated software solutions to be used by garment manufacturers around the world, nowadays there are several apparel CAD brands offering user-friendly version of cut order planning solutions.

How does a cut order planning software work?

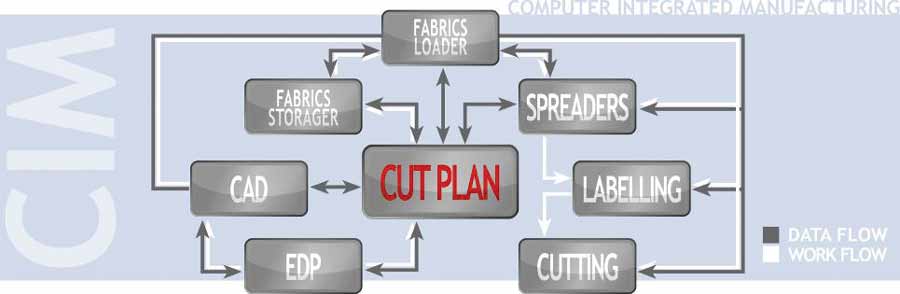

Cut order planning (COP) is a powerful integrated tool to optimize fabric utilization, cutting room process, timing and manpower by allowing the operator to choose the appropriate, balanced decision as per the scenario of style, orders, fabric availability and other specifications of the cutting room. The integration starts from fabric roll management, order management, marker management and interface with auto spreaders, auto cutter, auto labellers, bar code system, and ERP system for error free instructions and data management across departments. The costing module of COP finds out the optimized cost of cutting process before starting the production.

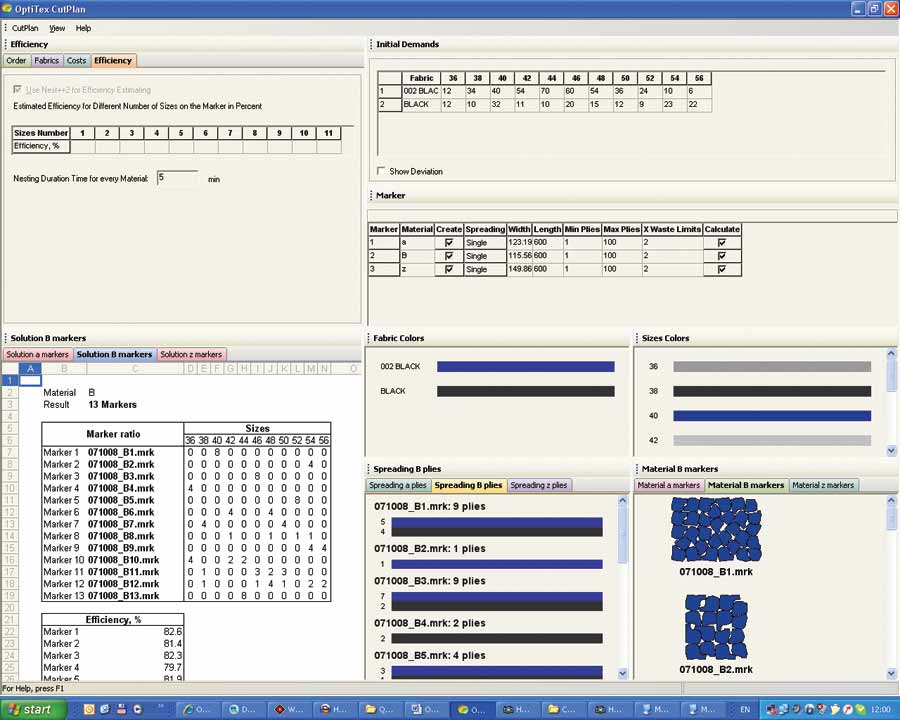

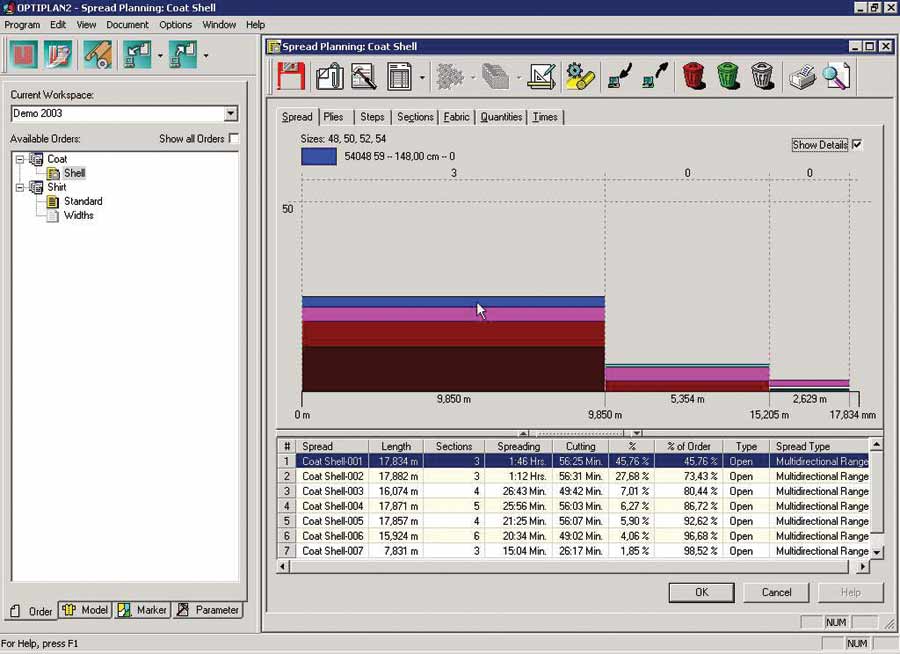

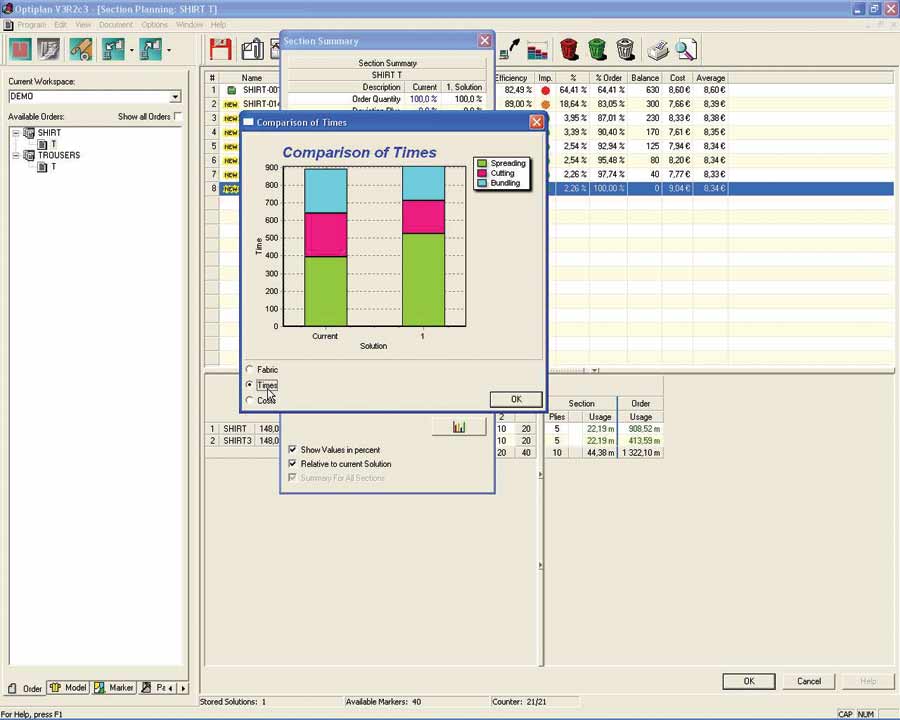

Cut Planning uses an efficient three-step process that begins with planning the optimum markers and plies required. Markers can be planned automatically or manually. Based on this information, a spread plan is automatically created that shows the required markers, marker lengths, material plies, and relationships to the cuts. When the spread plan is approved, cut orders are also automatically built, saving the labour intensive time associated with manually building cut orders.

The Fabric Roll Manager Module maintains the inventory of rolls with all information like supplier details, lot reference, received date, quantity and stock availability. It re-groups the rolls automatically as per width, colour, shade, shrinkage and provides the metreage of each group for effective cut planning. The Roll Assignment Module assigns the suitable roll to each lay of a cut order automatically and interactively. The Marker Manager Module manages the CAD marker database with details of style, size, and consumption. Before making any new marker, the module automatically checks the available markers to avoid any repeat. The new markers of an order are queued for auto nesting with necessary setting for one way garments, shrinkage, block cutting requirement and buffer. The Order Manager can combine, split, modify orders and increase or decrease the order quantity by percentage or available material quantity. The original order quantity and modified order quantity are stored for any future comparison. The program automatically/manually calculates the optimized/ best possible plan as per user settings.

Priority for fabric or time savings or both:

- Spreading type (face up, zig-zag, face-to-face)

- Maximum table length (lay length)

- Maximum height of spreading (number of plies)

- Single colour or mix of colours or step lay (for smaller orders)

Cut Planning uses an efficient three-step process that begins with planning the optimum markers and plies required. Based on this information, a spread plan is automatically created that shows the required markers, marker lengths, material plies, and relationships to the cuts

Cut order planning software determines what markers should be made; how fabrics should be spread and cut; the most cost-effective number of plies, colours and size mixes. It provides ongoing status report, stores data and nested marker (MRK) files, calculates quantity of order bundles and marker definitions, creates nesting markers for production, reduces material consumption, maximizes marker efficiency, and provides detailed spreading information for multi-colour plies. Such a software saves time when managing multi-colour orders and calculates production costs accurately for better management, while minimizing time-to-market by dramatically reducing development cycle.

Morgan Dynamics 903 Cut order planning

This is a fairly new solution offered from Morgan Dynamics, Italy. It includes CAD and product data management (PDM) in its software product range, and cutter, spreader, fabric loader and plotter in hardware product range. Thus it offers possibility of seamless integration amongst its product range. The only thing that goes against this solution is the lack of many peer installations for potential investors to compare. www.morgan-dynamics.com

Optiplan from Lectra

Lectra offers the legendary Optiplan software which was originally developed by Roger Dennison. The current version is made user-friendly and has many installations for peer review by potential investors. Lectra also offers CAD and PLM software solutions and spreader, cutter hardware solutions. The integrated product engineering solution is added benefit for future integration while absence of loaders is a negative. www.lectra.com

Cut Plan from Optitex

Optitex Cut Plan is a fairly new offering from Optitex family, known for its legendary CAD solutions. Optitex started offering cut plan solutions from 2009 onwards as advanced module under its CAD range of software. Like Lectra it has a strong integrated product development software suite, but it does not have its own hardware range of spreaders, cutters and loaders, making the seamless integration dependent on compatibility with other hardware. Being a relatively new offering in the market, number of installations is also limited. www.optitex.com

PolyPM

PolyPM cut plan is the offering from Polygon Software, US. Polygon software is very old software, offering CAD solutions to the world market and had a brief presence in the Indian market during 1990’s. The company recently re-entered Indian market with a whole range of software solutions. CAD and PLM and integrated ERP gives additional advantage for seamless interconnectivity, however as Polygon Software does not offer spreader, cutter, loader the investor has to depend on other brands for hardware solutions and connectivity. www.polypm.com

IMA 300 Cut Plan

IMA from Macpi Group of Italy is a fully independent joint-stock company. The IMA range of products includes spreader, cutter, loader and software solutions like Genious Evo CAD. Although spreader and cutters are well established, software products are just getting established. The advantage of IMA cut plan is that its software solutions like CAD, spreading and roll optimization software are integrated with cut plan software and having own spreader, cutter and loader is added advantage towards building a total cutting room solution. www.imaitaly.it

AMS Cutplan

AMS Inc. was founded in 1978 in US by apparel manufacturing managers with the goal of solving the optimization challenges presented in the fabric cutting process. AMS Cutplan is probably the only company which offers only specialized cut plan software without any other software solutions like CAD. Although AMS Cutplan have very strong presence in US and South America, it is relatively unknown in Indian subcontinent. The negative about this solution is that investor has to ensure seamless interconnectivity with other brands of CAD software and hardware products like spreader, cutter and loader. www.cutplan.com

Cut order planning benefits

Although every solution is different, there are many similarities between them and the overall benefits that can be achieved by using cut planning software are many. Among the most important is that the software helps in optimizing material stock management and achieves substantial material savings, as it allows precise calculation of how much material has been used and exact amount of fabric needed to manufacture, taking account of one’s specific environment, thus avoiding waste and stock shortages. Further, by streamline processes and maximizing production by grouping together the different planning stages into a single, automated process, fabric consumption can be reduced by up to 5%.

The cut planning software rapidly creates schedules and adapts them in minutes to ones daily production requirements. Through task automation, it also optimizes CAD and cutting activities and reduces the risk of error. The time saved by operators because of this application enables them to refocus on their core activities and save time in production management by up to 15%.

The multi-application versatility of the software automatically manages data sent by CAD and ERP systems via the automated import of new manufacturing orders and markers. It also links the different technology islands (planning, CAD, ERP and cutting room) and improves productivity as the software simulates production activities based on scenarios and measure their impact on material consumption and productivity.

No doubt, by working with integrated cut planning, businesses are able to maintain their production data in one central database which creates a more efficient operation and reduces errors while also facilitating decision-making.

Conclusion

While deciding on which cut plan to select, one must consider two things: What is the priority and return on investment. There are feature heavy solutions that may not be right for everyone. One should be very careful not to create islands of solutions. You may have the best CAD from one brand and best cut order planning solution from another brand; but they may not have seamless interconnectivity. Unless you’re in-house IT capabilities are very strong; you should stick to those which come integrated with CAD, spreading and cutting solutions. You must check whether you can set multiple priorities and generate different what-if situations.