The pandemic has today made it necessary for companies to adopt technology to function effectively and efficiently. That’s become the necessary requisite to survive and succeed in this ‘new normal’ world – the new normal that is marked by social distancing and everything that’s virtual.

However, there were few advanced and fast-paced companies that already knew about this direction, and had embraced the best of technologies to stay competitive much before the pandemic had arrived.

They were thus prepared to not only adjust to the ‘new normal’ world, but also come out winners in these tough times.

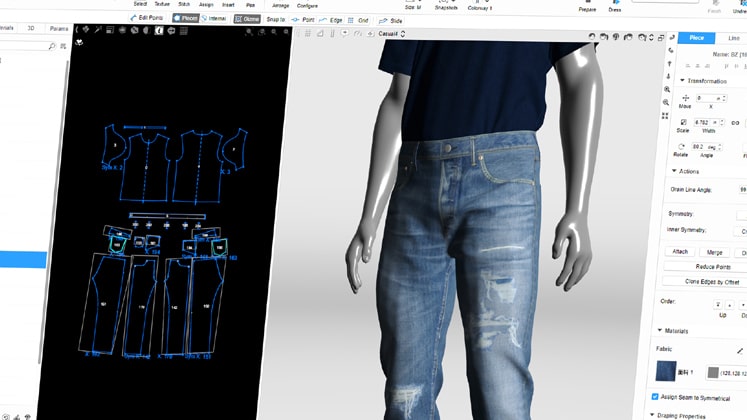

The renowned Hong Kong-based apparel manufacturer, Crystal International Group Limited is one such company that has scaled up 3D virtual sampling to redesign the product development process and thereby accelerated its digital transformation journey.

The Group’s search for a versatile and flexible technology ended back in 2017, when it first adopted 3D virtual sampling, and ever since it has been witnessing a remarkable growth in the number of samples that are being virtually developed every year. Importantly, it’s been a hit with customers as well.

In today’s times, when people are wary of going out and work from home (WFH) is the ‘future of work’, everything that’s virtual works and Crystal Group, as always, has been ahead of times. It’s already done what many are now planning to do.

While virtual sampling saves the cost and logistic time taken to deliver physical samples, it also helps bringing down the production time.

And it doesn’t end here! It’s eco-friendly too. Over 75 per cent of physical samples as well as associated materials, water and energy consumption can also be drastically reduced following adoption of virtual sampling.

We do not know how quickly world may be able to eradicate the pandemic, but social distancing and WFH are here to stay for some time and that’s why when the company says that by next year, 80 per cent of its self-developed products will be using virtual sampling, it holds relevance.

The company believes the numbers to go up to 90 per cent in the years to come. Virtual sampling too is the ‘new normal’.

The Group, which has around 20 production facilities across Vietnam, China, Cambodia, Bangladesh and Sri Lanka, endeavours to continuously enhance overall efficiency as well as accuracy, and lower production cost while meeting quality standards consistently.

It generates revenue of US $ 2.43 billion.