Team Apparel Resources (AR) presents a series of five technical articles based on the premium sewing thread range offered by A&E and Gütermann – a leading high-end thread provider – and its importance in the garment factories. The series will talk about the five different challenges faced by Sewing Machine Operators in factories. In the first offering, the detailing is shared by Seam Puckering which includes causes, contributing factors, and ways to minimise the same using its premium products in the portfolio. With an in-house sewing lab facility and Tech Centre based at Bawal Factory, A&E and Gütermann provides technical consulting services to brands and factories as the lab enables the company to perform R&D and random testing on the threads on all sort of new-age sewing machines such as SNLS, overlock, heavy-duty, flat lock, and button-hole offered by premium sewing brands such as Juki, Duerkopp Adler and Yamato.

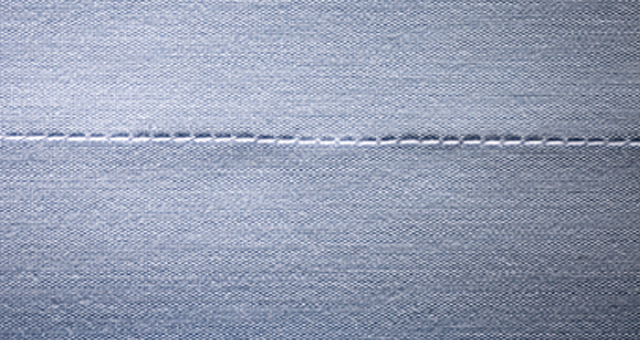

Seam Puckering is one of the persistent issues faced by the garment factories during sewing operations, causing to impact garment production time and quality drastically. It refers to the gathering of a seam during sewing, after sewing, or after laundering, causing an unacceptable seam appearance. It is observed that Seam Puckering is more common on woven fabrics than knits; and it is prominent on tightly woven fabrics.

The highly equipped Tech Centre and sewing lab facility addresses all the puckering issues head-on, caused by one or more of the following conditions –

- Yarn Displacement (structural jamming of fabric yarns)

- Tension Puckering (excessive thread tension and recovery)

- Machine Puckering (uneven ply feeding)

- Shrinkage (where seam components have differential shrinkage)

The lab gives relevant solutions as well on all the above-mentioned issues – that’s what makes A&E Gütermann far superior than other thread manufacturers in the market.

- Yarn Displacement (structural jamming of fabric yarns): Identification and solutions

Seam Puckering is more prevalent on very tightly woven fabrics because the yarns are oriented in tight layers that cannot shift easily to compensate for the thread as it is inserted into the seam. This causes these tight yarns in the fabric to draw up giving a rippled appearance along the seam line. This is usually more of a problem when seams are sewn in the warp direction than in the weft (filling) or bias directions.

Solutions to puckering caused by yarn displacement

There is a well-defined corrective action to minimise puckering caused by yarn displacement. The factories should use the smallest thread size available that will maintain adequate seam strength and sewing performance. Sewing threads specifically designed for minimising Seam Puckering on lightweight fabrics include brands Mara, Ultimate, Supra Seam, Perma Core Tex size ranging from 18 to 24. These threads are very strong for their size and have excellent frictional characteristics allowing them to be sewn with minimum machine thread tension.

Using smallest possible needle size will not cause excessive sewing problems. It is recommended for factories that they use a needle with a longer needle point, if available, which will have less resistance as it penetrates the seam. Another important step to minimise the impact of the said problem is using a needle plate with a small needle hole and finer feed dog.

Further, the number of stitches per inch (SPI) can also be reduced, so there are fewer yarns displaced in the stitch line to cause Seam Puckering.

When possible, cut the garment pieces so they can be sewn on the bias or in a direction that allows the different yarns in the construction of the fabric to be displaced.

- Tension Puckering (excessive thread tension and recovery)

If a thread is sewn into the seam with excessive machine thread tension, the thread will try to recover or return to its original length. This will cause the seam to pucker immediately as the seam comes out from under the presser-foot. However, sometimes the sizing or resins in the fabric will initially maintain a flat seam but later in the day, the seam will appear puckered. This phenomenon also occurs after the garment is laundered and the sizing materials are removed causing the seam to pucker and the inspector to think that there was too much shrinkage in the thread. Excessive thread tension during sewing will not only cause puckered seams but also cause other sewing problems including thread breakage and skipped stitches.

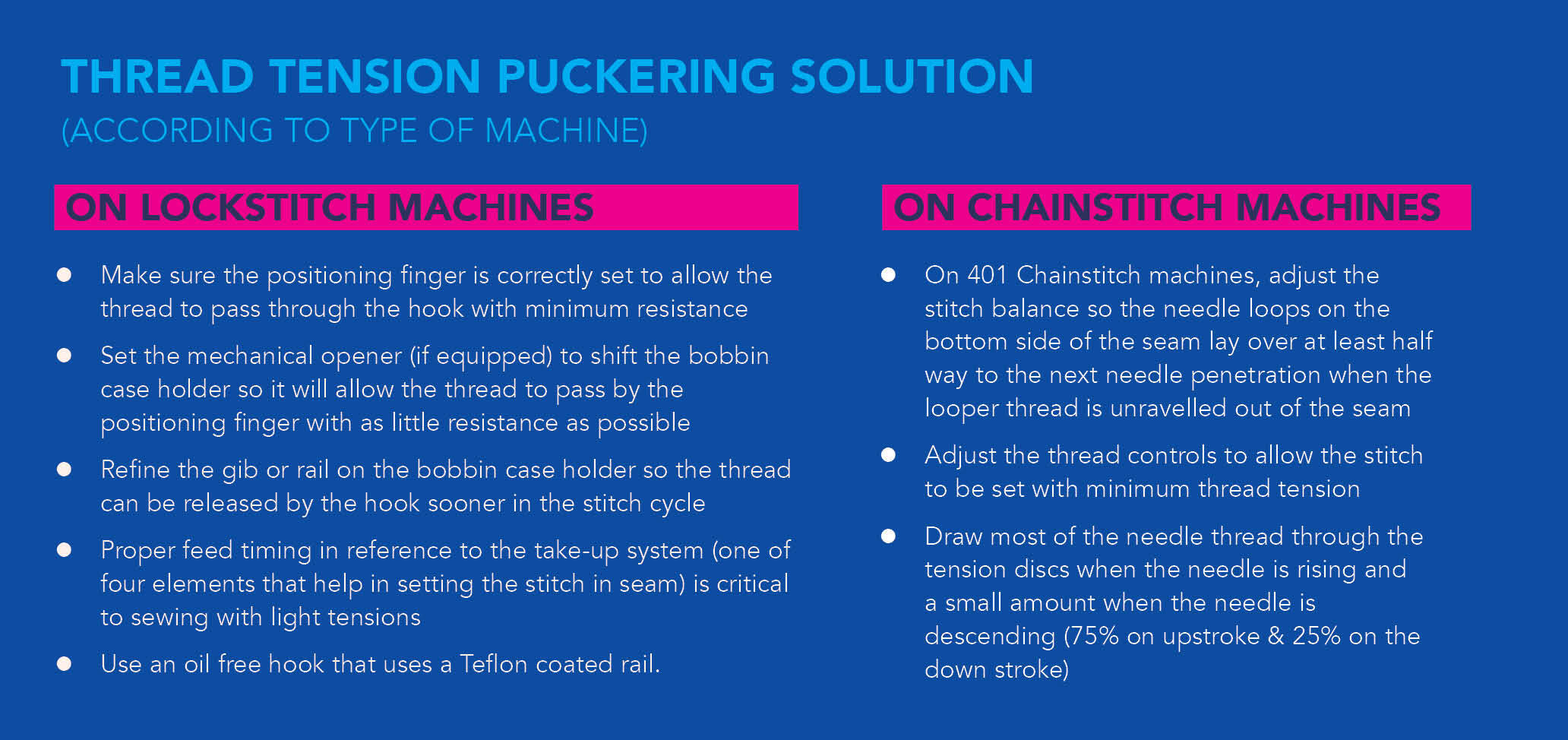

Solutions to Tension Puckering

The factories can use a thread with a low elongation or high initial modulus to minimise stretching during sewing. Additionally, using a thread with good lubricity characteristics that will allow it to be sewn with minimum machine thread tension is also a good way. We recommend to use Mara, Ultimate, Supra Seam, Perma Core brands as these are specifically designed to have these physical characteristics and they too have very high initial modulus or resistance to stretching under normal sewing tensions.

Alternatively, the use of very light machine thread tensions will also work. To do this, one has to begin by setting the bottom thread tension (bobbin or looper) as light as possible but still maintain the proper thread control. Now adjust the needle thread tension to a minimum level necessary to maintain a closed seam and a balanced stitch. This not only reduces the elongation of the thread in the seam, but also improves loop formation and sewability.

Reducing the thread size with lighter machine thread tension can also work because a smaller thread requires less tension to pull it up into the seam and set the stitch. We recommend using Mara, Ultimate, Supra Seam, Perma Core Tex-18 to 24 depending upon the GSMon ‘wrinkle-resistant’ or ‘no-iron’ lightweight fabrics, suits, coats, etc.

Also Read: A&E and Gütermann: A trendsetter that redefines the way thread industry works

Polishing or replacing all eyelets and thread guides can be a handy solution to make sure they do not affect the frictional properties of the thread. On some machines, a rotary tension system is available that meters the thread more uniformly than conventional tension disc systems. On other machines, the thread control guides and eyelets can be adjusted to control the thread more efficiently, so less tension is required. This is advisable when possible.

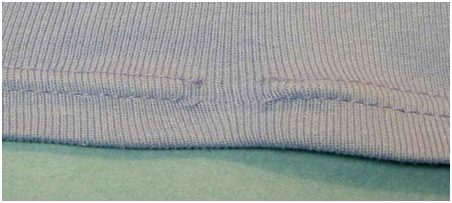

- Machine Puckering (uneven ply feeding)

Feed puckering occurs when one of the fabric plies is fed into the seam at a different rate than the other ply or plies. This causes a gathering effect in the over-fed ply. Ply mismatching usually occurs when –

- The presser foot holds back on the upper ply as the bottom ply is being fed into the seam at a higher rate by the feed dog;

- The operator holds back on the bottom ply and pushes the top ply into the machine so the fabric edges will come out evenly.

Many seams observed display both of these conditions, with the first usually contributing to the latter because the sewing operator will attempt to correct for the uneven feeding of the sewing machine.

Solutions to Feed Puckering

To minimise Seam Puckering caused by uneven ply feeding, the following corrective actions should be used:

- Use the minimum presser foot pressure that will maintain uniform feeding;

- Make sure the presser foot is clamping the fabric properly both in front and back of the needle. When the feed is up and moving the fabric, the seam should be clamped by the entire bottom surface of the presser foot. This can be checked by inserting a piece of paper under the foot from different angles and observing if the foot is clamping the fabric properly.

- Set the feed dogs at their proper height and check for back-feeding. The feed dog should have the optimum teeth per inch and number of rows of teeth for the operation and fabric being sewn.

- Use the correct presser foot and needle plate for the material and operation being sewn. The needle plate and presser foot should have relatively small needle holes in relation to the needle size being used.

- Use a low friction presser foot: Teflon coated roller bearing, ‘feeding foot’, etc.

- Use an ‘anti-puckering’ needle plate with a retaining spring that holds back on the bottom ply to match the top ply.

Apart from these solutions, A&E and Gütermann strongly recommends using machines equipped with auxiliary top feeding mechanisms such as walking foot, puller, top driven roller feed, upper belt feed, etc. On machines equipped with differential feed systems, set the differential action to slightly stretch the bottom ply to match the top ply so they are fed evenly into the seam .

- Shrinkage (where seam components have differential shrinkage)

Shrinkage Puckering can be caused when one of the components sewn into a seam shrinks at a different rate than the other components. Typical components include the shell fabric, interlining, zipper tapes, stay tapes and the thread. All these components should have minimum shrinkage to produce the flattest pucker-free seam.

Solutions to Shrinkage Puckering

A&E and Gütermann brands Mara, Ultimate, Supra Seam, Perma Core have been designed with controlled elongation with minimum shrinkage and the company recommends the mentioned brands to minimise Shrinkage Puckering.