Transforming a ‘science fiction’ into a ‘science fact’ yet again, the future of fashion and of consumer products lies not only in modernizing the very basics of designing, manufacturing and retail, but also in advanced technologies and materials, that are giving rise to a whole new world based on 3D technology. Costing millions of dollars in the past for developing expensive haute couture and avant-garde designs, 3D printing machines now cost as little as $ 1,000 and are about to become the next must-have technology for the masses to ‘value add’ garments.

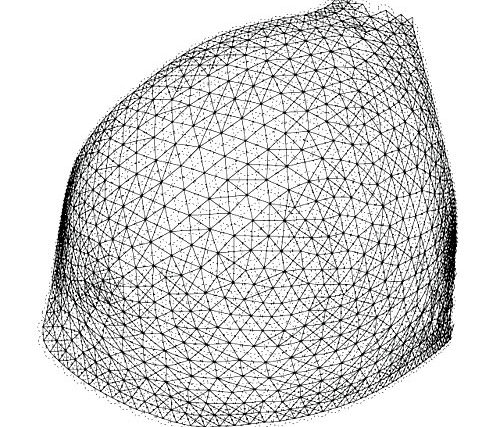

In simple words, 3D printing can be defined as an additive manufacturing process where a machine turns a digital file into a finished physical object by building up that object layer by layer. A 3D printer works by taking a 3D computer file and constructing from it a series of cross-sectional slices. Each slice is then printed one on top of the other to create the 3D objects. Once a novelty reserved for architects and product designers, 3D printing has been around for 25 years but it is only now that it is making its way into nearly every corner of the industry.

With designers and researchers experimenting for a long time with this technology for clothing, it is only now that they have tasted success, making it an affordable design.

One of the newest and most production savvy innovation in apparel 3D printing is the N12 bikini. It is the world’s first fully 3-dimensional, printed ready-to-wear swimwear created by Jenna Fizel and Mary Haung of Continuum Fashion in collaboration with 3D-printing company Shapeways. By using nylon discs of varying sizes connected by springs to create bikinis that “flow” around the contours of the body, the nylon is the perfect choice as its water proof quality makes it remarkably comfortable, even when wet. Now available in sizes ranging from 32 to 36 and cup sizes from A to D, the founders are working on a system that lets customers send in body scans and get their clothing “printed” according to their body shape.

One of the newest and most production savvy innovation in apparel 3D printing is the N12 bikini. It is the world’s first fully 3-dimensional, printed ready-to-wear swimwear created by Jenna Fizel and Mary Haung of Continuum Fashion in collaboration with 3D-printing company Shapeways. By using nylon discs of varying sizes connected by springs to create bikinis that “flow” around the contours of the body, the nylon is the perfect choice as its water proof quality makes it remarkably comfortable, even when wet. Now available in sizes ranging from 32 to 36 and cup sizes from A to D, the founders are working on a system that lets customers send in body scans and get their clothing “printed” according to their body shape.

The 3D technology has only recently found adaptation in clothing industry, as it gets faster, more user-friendly, with better quality and colour and less expensive, whereas it is already being used in various sectors like architecture, industrial design, engineering, automotive, aerospace, dental and medical industry, disaster response and the arts sector.

The garment industry abandoning the use of the traditional needle and thread, through this technology has brought different innovations in clothes, a substantial increase in speed of manufacturing the garment, and undoubtedly a huge reduction in the required labour inputs.

Meanwhile, the production of clothing can become more personal, can produce a variety of new customer needs style, and more and more ideas and designs can be developed using this technology.

The 3D technology has only recently found adaptation in clothing industry, as it gets faster, more user-friendly, with better quality and colour and less expensive, whereas it is already being used in various sectors like architecture, industrial design, engineering, automotive, aerospace, dental and medical industry, disaster response and the arts sector.

With the increased affordability of this process, it’s not hard to envision a world in which, 10 or 20 years from now, every home will have a 3D printer. The customers making shopping almost obsolete can print out a shirt that fits them perfectly and can create their own patterns, and plug in their own measurements for custom-made clothes, sports equipment, jewellery, or virtually anything one can imagine.

The 3D printing wave has at the moment caught the attention of some of the world’s biggest technology companies. HP, the largest paper-printer maker, has started reselling 3D printing machines made by Stratasys. And Google uses the CADspan software from LGM to help people using its SketchUp design software turn their creations into 3D printable objects.

As it is still too early to pick an industry leader for this technology, there are only a few companies in the field, and major players will enter as the technology becomes even more affordable. With so much possibility of exploration, altogether new businesses have cropped up such as Freedom of Creation, based in Amsterdam, designs and prints exotic furniture and other fixtures for hotels and restaurants. It also makes iPhone cases for Apple, eye cream bottles for L’Oreal and jewellery and handbags for sale on its web site.

Companies like Bespoke Innovations have used 3-D printers to make prosthetic limbs for the disabled. And in Belgium, a 3-D printing company named i.materialise just opened the first store for 3-D printed housewares.

Being observed as one of the most promising emerging technologies in the world, the key for investors is to figure out who will bring those 3D printers to the masses – and what company will provide the necessary cartridges, to make this the next big thing!