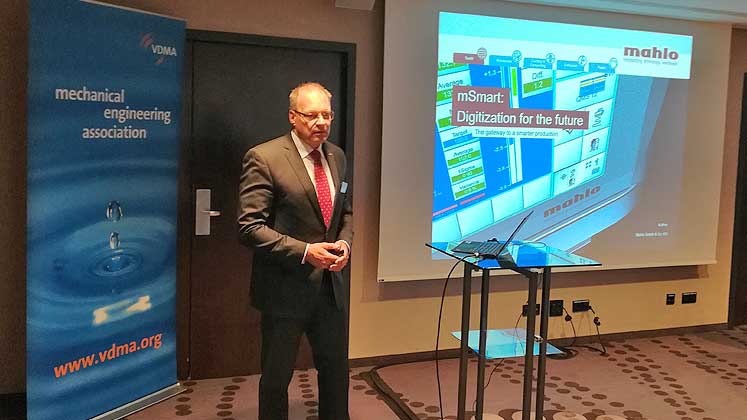

On the occasion of a VDMA press conference themed “ITMA countdown” in Frankfurt, speakers from member companies Lindauer DORNIER, Herzog and Mahlo showed how Industry 4.0 solutions are going to impact the textile process chain and what technologies visitors can expect to see at ITMA 2019.

On the occasion of a VDMA press conference themed “ITMA countdown” in Frankfurt, speakers from member companies Lindauer DORNIER, Herzog and Mahlo showed how Industry 4.0 solutions are going to impact the textile process chain and what technologies visitors can expect to see at ITMA 2019.

The products examples of the respective companies made clear that Industry 4.0 is no end in itself but helps to improve production processes and results and supplements the range of services.

Herzog, the leading company in braiding technology, CEO, Dr. Janpeter Horn, took the opportunity to introduce the company’s latest Industry 4.0 product. It unveiled an app-box with which the customer can easily access the data of Herzog and other machines, for example, on a PLC (Programmable Logic Controller).

The data can be visualised on dashboards created by the customer on terminals or others. The data can be processed, for example, by creating key figures, alarms or analyses. “Starting with Industry 4.0 does not necessarily mean to end up in a huge project and to employ software and consultant teams. We are offering an organic start into Industry 4.0 scenarios,” said Horn.

To realise this lean approach, the solution makes use of cloud technologies on the shop floor; open source technologies for inexpensive apps; no internet connection is necessary. The main advantage, however, is the “one-click” installation of apps which have been applicable only for smartphones and tablets.

Mahlo, the company that develops and produces measurement and control equipment for the textile and non-woven industry, introduced a new platform with the ideas of Industry 4.0 with digital technologies. In the digitisation concept for all Mahlo products, the functionalities are grouped, optimised and standardised as “services.” This results in modular hardware and software function blocks that can also be retrofitted resulting in more efficient and faster controller. “Evaluations confirmed by customers prove that the control module regulates 20 per cent faster and more precisely than before. Better straightening results reduce the production of second-choice goods and the need to pass the same fabric through the stenter several times.” Rainer Mestermann, Managing Director, Mahlo.

Dornier, leader in weaving machine technology, will present a new customer portal based on state-of-the-art database technology and will provide an online shop with permanent availability for original parts for all product lines. The innovation features remote maintenance and networking of weaving machines to improve run characteristics.

Also, the development focuses on making the job of machine operators and production planners easier. “Even in a 4.0 future, personal installation and maintenance support will remain an indispensable part of services but the portfolio will be supplemented by digital solutions,” stated Peter D. Dornier, CEO, Lindauer DORNIER.

“The future success of the textile industry is more and more determined by Industry 4.0. As seen today, Industry 4.0 has many dimensions and possible fields of application. In Smart Services, Operations and Factory, key solutions are provided by the machinery industry. Today’s presentations are just a few examples for innovative Industry 4.0 solutions.

At ITMA in Barcelona, visitors will have the chance to see the whole range of I4.0 and other innovative solutions offered by VDMA member companies,” said Thomas Waldmann, Managing Director, VDMA Textile Machinery Association.