Vertical and renowned textile giants like Vardhman, Nahar, Trident; top domestic brands like Monte Carlo, Madame; illustrious companies catering to export as well as domestic markets like Kudu Knit Process, Bhandari Hosiery Exports Limited; hundreds of growing domestic brands and thousands of unorganised players… nearly all segments of the textile industry in Ludhiana, a leading Indian knitting hub, are moving forward with full enthusiasm. With an overall annual business of more than Rs. 50,000 crore, there are plenty of challenges for all such segments, but coping with these obstacles, the industry is marching ahead, especially SMEs, which are as much impacted with all difficulties and have limited resources. Team Apparel Resources discussed at length with the industry players about the various issues ranging from industry’s growth, Government support and policy execution on the ground level, to the direction of Ludhiana’s apparel trade as well as individual development of companies.

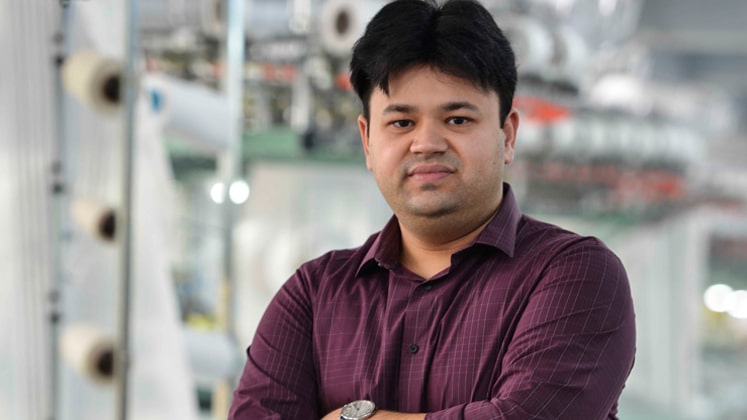

SME players unanimously agree on two points: the Government is not supportive at all and infrastructure is top priority. Government policies are not working right now and need a major revamp. Every Government promises to support new investment but in reality does not bother for the existing industries; so in this way, Government creates unhealthy competition for the existing companies. Ajit Lakra, MD, Superfine Knitters, is of similar view , “SMEs are in a very difficult stage even if they have good orders. This segment is not growing at the desired pace. One of the main reasons for the same is that entrepreneurs are forced to indulge in unproductive things (useless formalities and paperwork regarding various Government departments). They can’t afford highly paid professionals to tackle these tasks.” Associated with many trade organisations, Ajit Lakra is one of the most respected names in Ludhiana’s apparel industry.

It is pertinent to mention here that the industry was promised electricity at Rs. 5 per unit but rather than fulfilling that commitment, the State Government has increased the security amount and pressure on manufacturing companies. By and large, the industry strongly believes that the administration is not supportive and the majority of the policies detailing and implementation are so cumbersome that their benefits don’t percolate to the needy ones. Even in some cases, Government employees are not aware of the schemes and unnecessarily object to the execution of the specified policies. Forget GST, even old VAT refunds are not cleared.

Ajit informs, “We have invested around Rs. 7 core in the last three years but did not apply for any support in this regard as we don’t wish to waste our time and energy as we are not sure we will be getting any benefits.” He further adds that the industry needs ease of business keeping good infrastructure on top.

Sanjay Jain, Director, Ferro Sona Garments, has experienced the same, “We could not avail any major benefit as policies of Government are quite typical and very hard to understand. There is corruption everywhere and all this is hurting business growth.”

Akhil Sachdeva of Pinnacle Knitwear also shares similar thoughts, “Regarding policy and support, nothing has reached the grassroot level. We want that Government should come up with some initiatives – be it general infrastructure and financing the capital for investment. Incentive programmes are really needed. Even the land available in Ludhiana, be it textile or apparel park, is not at the preferred scale or level and access to that land is not too much easy.”

“There is a very important fundamental shift happening in Ludhiana; buyers who were placed out of place in the organised and export segment had a fearsome image of Ludhiana, and were surrounded by several apprehensions. I think that there has been a change in the thought process now. There are few set–ups including us who are focusing on this as an opportunity and we are able to get better business Y-o-Y from this segment. Buyers need to be more open-minded; they don’t have to carry that stigma or hallow effect of old Ludhiana image. They must explore new-age business from Ludhiana,” mentions Varun Mittal, Director & CEO, Kudu Knit Process.

This is the transitional period to discard conventional technology and opt for new technology but proper support is not there like poor execution scheme for technology upgradation. Apparel entrepreneurs have raised valid objections like in case of Government imposing import duties even when most of the machinery are not manufactured in India. Why are these machines not manufactured in India?

CETPs: Work in progress… Near completion!

Some of the infrastructure-related issues seem to be pointing towards the solution. One of the most important of them being Common Effluent Treatment Plants (CETPs). There are around 300 good dyeing units in the city and to support them, 3 CETPs, with a total capacity of 105 MLD, are under process. Overall investment in these CETPs is more than Rs. 155 crore (collectively by State and Central Governments as well as by the industry members). The issue is pending for almost 10 years and finally got some speed, as overall 75 per cent work has been completed so far. Civil work of CETP at Focal Point, with a capacity of 40 MLD, has been completed by more than 92 per cent in the meanwhile. Deadline for the same is 31st March 2020. Punjab Pollution Control Board (PPCB) has warned that no further delay will be tolerated in this regard and funds from the Government regarding the same will be issued on priority basis. CETP at Tajpur Road with 50 MLD capacity has been completed by 45 per cent. It is expected to start now on 31st June 2020. CETP of 15 MLD Bahadur Ke Road has also started. Though the industry needs two more ETPs to work comfortably.

No new dyeing unit will be allowed to function within the municipal corporation limits once CETP comes up in the city.

Meanwhile, Punjab Dyers Association (PDA) also got some relief, as the National Green Tribunal (NGT) has directed the Ministry of Environment and Forest (MoEF), Government of India, and the Punjab Pollution Control Board (PPCB) to remove the condition wherein the association was asked to construct an irrigation channel for availing the grant of Rs. 22.5 crore for the CETP project at Tajpur Road.

It is pertinent to mention here that all treated water from these 3 CETPs will not be reused and will flow to Budha Nala (a seasonal water stream) as the project to use this water for agricultural purpose is still on hold with the Soil and Water Conservation Department.

Company growing

Superfine Knitters

Strength/capacities: One of the most advanced garment manufacturing companies in Ludhiana serving as the turnkey project for many leading brands and retailers. The turnover of the company has increased and is expected to touch Rs. 100 crore and further profits are also expected to increase.

Expansion: The company started upgrading three years ago, achieving most of its targets like production efficiency. It also invested in six circular knitting machines (including lycra-based open width) which are of high speed. Similarly, its washing plant with a capacity of four tonnes per day (specially for dyed yarn) is working very well. The company has also invested in screen printing infrastructure.

Companies on their toes to grow

Kudu Knit Process

Strength: Promising end-to-end solution for all the gauges, ensuring all permutation and combination of processes so that all kinds of knit-based requirement can meet at one point. It deals in all kinds of knitted fabric and apparels including tops and bottoms, men, women and kids. Its forte are sportswear and performancewear.

Expansion: The company invested good amount on the modernisation of the plant; new plant of knitting commissioned recently where 22 knitting machines were added (open width with spandex, single and double jersey). Its further target is now on garmenting. The company partnered with Adidas for fabric supply.

Capacity

Yarn dyeing: 5-6 tonnes per day

Fabric dyeing, procession: 450 tonnes per month

Fabric printing: 75 tonnes per month

Garment: 3 lakh pieces per month

Strategy: The company’s focus is on organised segment including domestic brands and exporters. Following SDG seriously, the company is focusing a lot on sustainability. Recently the company got GOTS approval, BCI, Sedex and is in further process for GRS. The speed of R&D has increased quite a bit, as the speed at which the company is making a new product is higher than ever before.

Growth: 12 per cent Y-o-Y, but in the current scenario, it will be a little less.

Pinnacle Knitwear

Strength: 6-year-old woollen garment company which is now entering into other segments also like woven

Expansion: So far, the company was majorly into womenswear; last year it added menswear and now it is planning to enter into kidswear segment. Kidswear is always a priority for any family and as kids grow very fast, parents have to buy new clothes every year. The company is increasing its production capacity as well as outsourcing heavily as it has good tie-ups with quality job workers. The focus is also to develop own brand, target corporate sector, contract manufacturing and tie-ups with leading brands.

Capacity:100 thousand pieces per year (own manufacturing)

500 thousand pieces outsourced per year

Growth: 20-25 per cent

Ferro Sona Garments

Strength: With in-house knitting, stitching, and finishing, the company produces 10,000 pieces of knitted garments per day which is three times higher than its previous capacity. Producing men’s tees, lowers, and sweatshirts, the company is an expert in chest print. The organisation is working for the domestic market and has good corporate clients like Vmart, Dmart, V2 and many more. It shifted two months ago to its new premise, covering an area of 1 lakh sq. feet due to the expansion plan, added few new clients and increased business with the existing ones.

Strategy: Known for low cost and best quality, the company buys yarn in bulk (at least 100 tonnes) and produces garments in volume. It will keep its focus on basic garments only and will try to continue to reduce costing.

Growth: Every year it has grown by 20 per cent and the same is expected in the coming years.

Future Planning: It may go for automation and can install CAD. It will also explore the export market (especially the Middle East), as earlier it used to do export but discontinued.

- Ludhiana can be much better in synthetic-basedproducts if Chinese import can be curbed.

- Garments made by fancy yarns; newer blends are strength of Ludhiana. The city has good dyeing capacities,and now the dyeing quality is further

- Ludhiana’s tilt towards second machines hasnow reduced. Whatever second–hand machines are in demand, they are branded and in good condition, giving value for money.