Leather garments have a fan following from young bikers to high-society men and women addicted to the skin. From very basic leather garments using cheaper hides to very high-end fashion leather jackets and accessories, the market has something to offer for every enthusiast. A traditional producer of leather, India has over the years positioned itself as a high-end player working in smaller quantities and with greater emphasis on textures, finishing techniques and use of better quality leather. Team Apparel Online met up with four leading exporters in leather garments who are very upbeat of the future despite a few bad years…

Today, leather garments account for about 12% of total leather exports from the country, which is far below the potential, considering that India is among the top exporters of leather hides to the world. Yet, in the last three years, exporters of leather products have hit a roadblock and in the Delhi-NCR region, which is the hub for leather garments, the number of players has dwindled from 23 significant players five years ago to just about 11 players, all of whom admit that it has been a very difficult phase for the industry. Though factories in north are ahead in innovations and risk taking, factories in the south are cheaper compared as their overheads are less and factories are in remote areas.

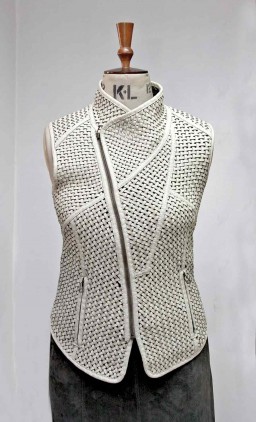

Despite the bad patch, exporters in the Delhi-NCR region are still upbeat and believe that the road ahead for the industry is very positive. “I see a good market ahead, as leather jackets move from winter wear category to fashion wear and India strengthening its position based completely on its ability to innovate for fashion,” says Sunil Kapur, CEO, ABC Leathers. Adds SK Singla, MD, Discovery Leathers, ‘Even today factories which have new techniques to show are in demand for buyers looking at higher end market segment.” No wonder the focus for all exporters today is on innovation, as leather jackets, which dominate leather apparel exports from India transcended from being a very basic and luxury item to a fashion commodity in the past 10 years. Colored leather, washed, metallic and embossed finishes; chemical treatments, contrast and decorative lining, prints, trims and value-added details are the variants most of the buyers are asking for and on which the market is thriving as a whole.

While Mago Exports headed by BB Mago has been getting orders for colours like cognac, fuchsia, camel, tan and blood red and have also produced a lot of pieces with dip dyeing and some pieces with studs and perforations, Discovery Leathers have witnessed a demand for navy blue, parrot green, mango in addition to red, camel and tan for colored jackets. With some orders for croc textures, metallic finishes and wax treatments; it has also successfully catered to orders for raccoon fur for the Russian clients along with a demand for pastels for the fall of 2014.

Though coloured leather has been a craze in the last decade, the range of colours in a collection has declined and while earlier exporters were doing as many as 50 colours at a time, now brands are playing with two-three major colours in a season. A brand’s complete collection will move around those colours. This is also a strategy to keep their inventory down, as managing so many colours is difficult. Exporters working with different buyers are aware of the colour |scheme for the season and they work accordingly.

At ABC, the feel of the garment is a very important selling point and though most tanneries are using chrome based chemicals for finishing, the company is now looking at using vegetable and semi vegetable dyes, which are expensive, but are much more environmental friendly. “Even as the world goes eco-conscious it is important to start looking at options and I firmly believe that in the next 5 years chrome-free tanning will be a norm, similar to azo-free dyes,” says Sunil. Currently a lot of R&D is going into finding cheaper ways to replace chrome in tanning.

For India the way forward is to give value-added product and most of the R&D is at the tanning stage. In such a situation having control over the tannery is a distinct advantage. In fact Saru International, which is catering to French, German and Spanish buyers and working with brands like Zara, T&H, Tommy Hilfiger, Camel Active and Z&V claims that it is a preferred supplier as they are backward integrated and using latest Italian machinery and software like Gerber for pattern cutting. “We have everything in-house from raw skins to shipping, so buyers know that they can depend on us. Also since 80% of the cost of the product is skin and innovation is at the tannery, we can give new finishes and washes that justify our fob of around US $ 80-90,” says Sandeep Mago, Director Saru International.

BB Mago, MD, Saru International with son Sandeep Mago, Director, Saru International

Sanam Siddiqui, Executive Director Evergreen International agrees that having a tannery is at the core of growth. “I personally look after the tannery we have in Hyderabad and initially it was difficult being a girl, but that is where the value comes from whether it is colour, texture, finish or feel. We work to give new looks on the skin and one of the most important, but underrated jobs is to assort the skins. In fact, selection of the skin is important for any new development for consistency and finish in the final quality of the product, which fetches us higher UVRs,” says Sanam. From selection of the skin to using the best chemicals to experimenting in finishes, buyers appreciate and pay for the value added by each process.

Interestingly, while most agree that having one’s own tannery is a distinct advantage, Sunil begs to differ. “We closed our tannery two years ago as we felt that it was restricting our creativity,” says Sunil. The company now has the option to work on many types of skin and scout around for innovations while offering shorter lead times, as they don’t have to wait for the tannery to give prepared skin, but can straightaway buy as per their requirement. “As our parent company Richa Global is having a very good washing unit we are experimenting a lot on washing techniques on skin, mostly lamb to show our buyers. Since buyers prefer to give their own cuts, our contribution is giving them new concepts in techniques, lining options for the jackets and accessories to work with,” adds Sunil.

Reasons for decline in business

Despite a traditional base in leather, many factors have played devil in retarding growth including the lack of timely Government support and the rise of Pakistan as a low cost option in the mass category, eroding the volume business in the last few years. “Even as fob prices rise, the cost of raw materials have seen major increase by around 30-40% in the last two years,” says Singla, who is working with buyers like C&A, M&S, Miss Sixty, P&C and Diesel in Europe, besides some buyers in the medium to upper segment

in the US.

The steep price hike in raw materials is also because of the fact that China has been blocking leather capacities over the two years ago from major leather centres like New Zealand, UK and South Africa, and the best leather produced in the country is being exported to Italy, Spain and China, where they fetch much higher value than if they are sold to Indian leather manufacturers. “The biggest constraint today is the unavailability of quality leather. Even importing good quality is difficult as good quality leather is scarce and those who do have the required quality are asking down payment, as there is a cash crunch in the market,” says Sunil. The major buyer for ABC is Hugo Boss.

The steep price hike in raw materials is also because of the fact that China has been blocking leather capacities over the two years ago from major leather centres like New Zealand, UK and South Africa, and the best leather produced in the country is being exported to Italy, Spain and China, where they fetch much higher value than if they are sold to Indian leather manufacturers. “The biggest constraint today is the unavailability of quality leather. Even importing good quality is difficult as good quality leather is scarce and those who do have the required quality are asking down payment, as there is a cash crunch in the market,” says Sunil. The major buyer for ABC is Hugo Boss.

[bleft]INTERNATIONAL LEATHER TRENDS

- Coloured leather: teal tones, ox-blood red, tan and brown

- Short biker jackets and trench coats for women

- Fitted jackets and trenches for men

- Combination of leather with fur and animal prints

- Patent and matt leather finishes

- Pullover like shirts in leather

- Quilted leather for puffer jackets

- Zipper details, perforations and riveting [/bleft]

Ironically, while the value of exports has continued to register growth, mostly because of the increasing FOBs, the volumes have been decreasingly consistent at around 20% in the last three years. It may be surprising for many, but China is not really in competition with us, as they are much bigger players and over the last two years with cost of production going up they have been refusing orders that are very price-competitive preferring to work on higher values. Pakistan, which has lesser players but bigger setups has taken major strides giving us really competition on price. “We are offering leather garments for an average US $ 80, while Pakistan is offering an average price of US $ 45, mainly because of scales and more basic styles,” says Sunil One of the biggest losses for the Indian market in the price war has been the loss of GAP as a buyer. At one point of time Gap was purchasing huge orders from India with ABC claiming to have done on an average 40,000-45,000 pieces per style regularly at an average FOB of around US $ 50. But as raw material became difficult to procure and cost of production increased Gap moved into Pakistan and Indian exporters lost out on the volume business. The global market slowdown too has had its impact, as the overall demand has also dwindled.

Industry looking for Government support

SA Siddiqui, Chairman, Evergreen International

Even as the industry players on individual level step up their efforts to give value, they are also looking for Government support to give necessary trust to the industry. The industry is pursuing the Government to monitor leather exports and give first preference to domestic consumption rather than allowing the best hides to be exported. “We are asking the Government to create a hide bank, which can store a basic stock of raw materials so that industry players do not have to decline orders for want of good quality hides. Also we are requesting for loans at nominal interest rates from banks to finance business,” says SA Siddiqui, Chairman, Evergreen International and Member Administration Committee, Council for Leather Exports (CLE).

Another demand is the setting up of a leather cluster like those coming up for textiles with complete infrastructure to enhance global business. Siddiqui informs that the cluster exercise is already in process at Sohna near Gurgaon where almost in 100 acres of land has been allotted to CLE. “Trained manpower is a major constraint in the leather industry, but now with the allotment of land to create a leather cluster we are setting up training facilities which will be a big support to the industry,” informs Siddiqui.

[bleft]

India’s export of leather garments increased from US $ 309.91 mn in 2006-07 to US $ 572.54 mn in 2011-12, growing at a CAGR of 13.06 per cent.

India’s export of leather garments accounts for a share of 11.76 per cent in India’s total leather trade of US $ 4,868.71 mn in 2011-12.

[/bleft]

The industry is also demanding an enhancement of drawback duty as other promotional schemes are not much helpful and require a lot of paper work. Bounded warehouse is another requirement especially for north to reduce leather scarcity. The industry is also looking at support to enhance the tannery base so that Indian exporters can grow on the value business. “China may be looking at higher value business, but the reality is that they have the reputation of a copier, while we do most of the things by hand. So we have the scope but we are not cashing on it because of constraints beyond our control,” argues Siddiqui.

Many of the exporters are now looking at new markets for growth. “The Council for Leather Export is doing good job in aiding new market access by extensive market research and regular BSMs. Our company got good response from South Africa, China, Canada and Russia as we took part in some BSMs. Latin America, Middle East is another good market which we need to explore,” says Singla. However BB Mago of Saru International differs. “One should explore new market, but in this tough time it is very risky. We have seen that even if you produce hundred per cent quality products, new buyers raise questions and create problems in payment. So the best option is to work with old buyers with whom you have good relation and faith. Taking too big orders is another risk in current phase,” he argues.