Climate change is increasingly recognized as a major challenge by people, Governments and businesses across the world. This change has been the result of uninterrupted exploitation of Earth’s natural resources for human activities leading to excess greenhouse gas (GHG) emissions. Excess GHG emissions have been primarily due to increase in power generation, industrial production, transportation, land use and waste. Carbon Dioxide is the main component of GHG emissions. Other gases include methane, nitrous oxide, sulphur hexafluoride, etc. These gases result in global warming by accumulating and absorbing radiation, thus trapping the energy received by the Earth’s atmosphere. Samit Jain and Mathangi Ramakrishnan of Advit Foundation, which is dedicatedly working in this core area, share their findings of working with the garment industry to improve energy efficiency…

[bleft]It is estimated that substantial power of over 4.6 lakh units can be saved in the Indian apparel industry. An investment of Rs. 40 lakh can bring an annual savings of Rs. 19 lakh, resulting in a payback period of approximately two years. [/bleft]

With environmental concerns on the rise, leading retailers sourcing from Asian nations are also worried about the high energy intensity of their suppliers and increasing Carbon footprint reduction obligations of the developed world. These days major global retailing firms are taking into consideration not only the cost competitiveness of suppliers but also their social, environmental and Carbon footprints.

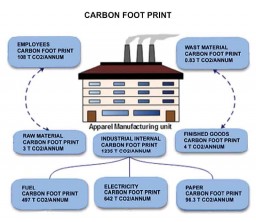

It is estimated that the textile and apparel industry accounts for about 9-10 per cent of the total industrial energy consumed in India and contributes to about 3 per cent of the global GHG emissions. Globally, this industry is facing increasing pressure to reduce its Carbon and environment footprints.

Apparels and Energy Efficiency

Businesses across the world are recognizing the need to be climate responsible and are investing in technologies, products, processes, systems and procedures that enable them to adopt sustainable practices and improve efficiencies. Most importantly, awareness of climate change is steadily influencing the consumer buying behaviour. The apparel units in India are slowly witnessing demands from their global customers to not only become Carbon responsible but also to constantly monitor and report their footprints.

Considering the entire lifecycle of textile manufacturing, main sources of Carbon emissions are farming and spinning. Use of good Carbon management practices can significantly reduce emissions from raw materials, waste and manufacturing. Use of organic cotton from local producers, natural irrigation, renewable energy sources (solar, wind, hydro, biomass, etc.), biodegradable packaging and transportation in following order of preference – water based (shipping), railways, roadways and ‘no airfreight’, can significantly reduce

GHG emissions.

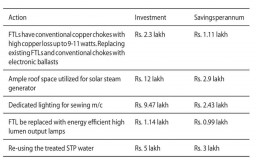

Common energy efficiency measures identified in the apparel units include – Replacement of existing inefficient FTL with energy efficient high lumen output FTL; Installation of voltage optimizer in lighting circuits to achieve energy savings; Replacement of conventional light bulbs with energy efficient lighting like LED, etc.; Installation of solar steam generators to supplement steam generated by diesel fired boilers (the diesel consumption will be reduced); Replacement of existing conventional regulators with EE electronic regulators; Pre-heating of oil with boiler exhaust gases; Reduction in water wastage & replacement of standard motors with energy-efficient ones; and Replacement of existing conventional electro-magnetic ballasts with energy efficient electronic ballasts.

Investments and Payback Period

A successful climate change strategy for apparel industry can bring tangible returns through cost savings from improved energy management and operational efficiencies, as well as greater market share and revenues by means of providing low Carbon apparel products.

[bleft]An energy audit is a great starting point for any organization wishing to reduce its carbon footprint. It was in fact our first real insight into what it really means to ‘Go Green’. The audit has helped us identify and improve performance across various areas not usually monitored in a typical garment factory.” – Akshay Kapur, Director – RADNIK Exports [/bleft]

Based on financial assessment of the energy efficiency opportunities identified for implementation, it has been demonstrated that substantial power and energy can be saved in the Indian apparel industry. It is estimated that over 4.6 lakh units of power can be saved. An investment of Rs. 40 lakh can bring an annual savings of Rs. 19 lakh, resulting in a payback period of approximately two years.

An investment grade energy audit coupled with GHG inventory management is a first step in this direction that helps the units understand current energy consumption scenario across operations, prevailing inefficiencies and energy losses in the process, identification and evaluation of alternatives that will result in energy savings, cost benefit analysis of supply-side investments, annual green house gas emissions resulting from operations and strategy to reduce and monitor GHG emissions.

Need is now to conduct Energy Audits

With the increased focus of global buyers like H&M, Walmart, IKEA, Gap, Indisca, S.Oliver and others, to source from Carbon responsible businesses, the Indian apparel industry needs to move fast towards adopting energy efficiency and GHG reduction measures. To cope up with these emerging trends, the Indian apparel units need to pro-actively initiate measures such as conducting an energy audit of the facility and operations to establish and implement measures that will result not only in energy conservation but also in positive changes in their operations and the resultant bottomline.