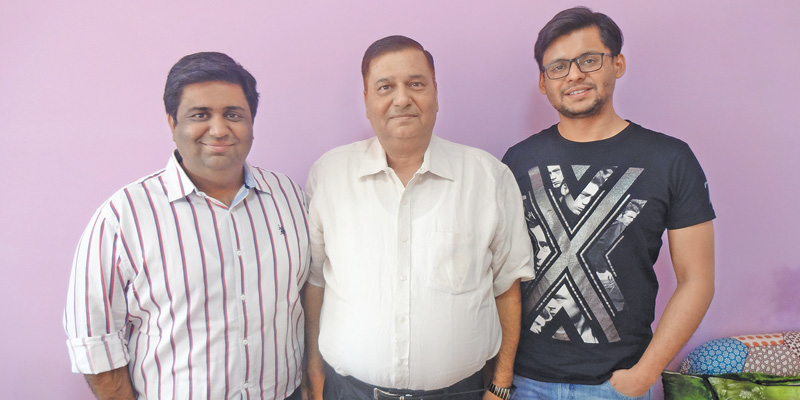

Be it home furnishing or apparel business, the number of 100 per cent EOUs in India is continuously decreasing. Convergence of global and Indian markets is on the increase and most of the manufacturers feel that now there is no major difference in working and expectation of both markets. Conditions are becoming same and global markets are losing their craze which earlier was a big factor for many manufacturers to opt for exports. Bella Casa Fashion & Retail Ltd. (formerly known as Gupta Febtex), Jaipur’s biggest and first ever public ltd. textile-based company, and the only one doing turnover of more than Rs. 100 crore (US $ 16 million) has lived through this journey from being a complete export-oriented unit to a majorly domestic manufacturer. Apparel Online recently met the duo of Harish Gupta, Chairman and Saurav Gupta, CEO of the company who have more than 55 per cent of share of business in the home segment for an exclusive interaction.

The company that completed two decades of its existence in February this year, was till 2004 majorly into exports, but disheartened by global market conditions and lack of buyer loyalty, the company changed its focus and strategy which proved fruitful. From a turnover of Rs. 8 crore in 2004, the company is now expecting a Rs. 125 crore turnover in current fiscal and the target is to double the turnover in next 2 to 3 years. Harish, who claims to have been instrumental in bringing many organized retailers to Jaipur, answers why this shifting took place, “I don’t see much difference in working of export and organised domestic retail markets, almost the same processes are in place, be it testing, delivery or quality parameters. We don’t like to work every time with new buyers, which is a common tool of growth for most of the exporters. Our priority is our old customers that are mainly into domestic retailing or a few that are working in Middle East countries. We don’t see any additional benefit or profit in exports. Whatever capacity we have is already booked by domestic brands/retailers. We are the highest tax payers and have highest number of employees (nearly 1,600) as far as Jaipur textile industry is concerned. Market is very good for us as we don’t see any problem in procuring orders from various sources, be it export or domestic. What else can one expect from their business?”

The company has a very saleable product mix which is created by a team of 10 designers. Customers select their collections directly from these designs; this strategy gives 4-5 per cent premium on rates to the company. “Be it quality of finished product, infrastructure or raw material usage, we are as good and advanced as any other top exporter,” claims Harish. Bombay Dyeing, Landmark Group, Lifestyle, Pantaloons, Reliance, D-Mart and HyperCITY are some of the top clients of the company for both home and apparel products.

The growth potential in the domestic market is immense according to the duo and Harish claims that expanding to a turnover of Rs. 1,000 crore is not difficult as his customers are asking everything from him; be it kids’ wear/men’s wear or anything in textile segment. “Being a master in textile I can do many product categories and customers come to me on their own,” he claims, but simultaneously argues that the same is not true for exports. “There is value for increasing capacity in exports only when we can dedicate a complete floor to a particular product category; however, all this is possible only if we can manage labour and land issues, further orders in exports are small and not regular. Currently, we are reasonably stretching our capacities which we can manage easily. Areas of 2,00,000 sq. feet is already available and construction is going on for one more floor. Though we are always on time in domestic production, but even a single day’s delay in deadline is an issue for exports and you are totally depending on the mercy of buyer which we don’t want. Further, we can’t sell that merchandise to others while in domestic if one does not take it, another will happily go for it. Whatever we do is quite on time, but international buyers don’t have any loyalty or stability to appreciate that,” Harish adds.

DESPITE customization and various product categories, the company runs its factory on shift system. the Management makes it sure that every shift should start under their supervision so that it does not hamper productivity. There are multiple assembly and finishing lines in the 3-product divisions.

Non availability of talented medium-level management professionals is another obstacle to focus on export, he continues. Family involvement is must in this business due to labour dependency. “The owners have to be involved and spend nights in the factories during production to ensure that everything goes on smoothly. There is no professional who works like an entrepreneur despite offering a good salary, proper support and guidance. I am missing result-oriented middle-level management who can work with the entire team. Whatever salary they want I can afford but they have to give quality production on time. It is not only my problem, but the problem of this hub,” he says.

The company has an automatic quilting plant and Harish shares an interesting memory about it. “I saw automatic quilting plant in China and was impressed as the meanwhile was making a quilt within a minute. We were not having even a single buyer of quilt at that time and the machine was costing us almost Rs. 1 crore, yet we decided to install it and invest this huge amount; besides it was easy to operate also. Even today, none of the companies in Jaipur have this facility. We run quilts 12 months on this plant and there is no off-season for this winter-base product. Due to this we are very cost-effective and are able to offer quality products.”

GenNext point of view

The company is a perfect combination of GenX and GenY as brothers Harish and Pawan Gupta initiated the business and now their sons Gaurav and Saurav carry forward the tradition. Saurav, Ex-Niftian and CEO of the company who joined business in 2004 is focused more on mass manufacturing concept. “We prefer the products which have replenishment demand. We invested a lot in machines after having consensus that we should do everything in-house. From 100 per cent export to a major shift towards domestic market was a challenge, but overall conditions were also in favour to work in domestic market as it was picking up during those days. From last 12 years we are happy with this strategy. Now we are not going to change our basic strategy in terms of market focus and mass production and make basic products completely in-house. In the same way we would like to increase market and production capacities too. All members of the team should follow SOP and nobody should ask for any exception. The salary we are offering is much-much better than any other factory of Jaipur.”