China is the world’s manufacturing hub for OEM (Original Equipment Manufacturer) sewing machines, and keeping up to that reputation, approximately 80+ Chinese OEMs were displayed at CISMA. The epicentre of sewing machine manufacturing in China is Zhejiang Province (known as China’s Sewing Machine Capital). Cities like Taizhou (Jiaojiang, Huangyan, Luqiao districts) and Ningbo host hundreds of manufacturers and are home to global brands like Jack, Zoje, Typical, Shunfa, New Baoyu, Jiaolong and many mid-size producers. As many as 36 OEMs from this province displayed at CISMA. So did the visitors witness some revolutionary technologies in sewing machines? The answer is yes and no.

First the Yes Part: visitors saw some machine features, once thought ‘exclusive’ as standard in each sewing machine. There are some fundamental changes happening in the industry and machinery technology also has to be in sync with it. As Jack puts it nicely “Clothing production is shifting from large scale single production to small scale flexible production” and hence the machinery needs to be flexible. With personalisation of clothing, transparency in transaction and ‘free information – increased awareness’ syndrome, quality becomes important again. The age-old stitch quality parameters such as consistent stitch length, no-birds nest, no-pucker seam, etc., are becoming relevant again.

First is the stepper motor-driven feed system that offers inherent mechanical benefits which align with sewing applications as under:

- Precise, repeatable positioning: Each pulse corresponds to an exact movement—no need for feedback loops.

- High torque at low speed: Excellent for stable fabric feeding without slippage.

- Simpler, cost-effective control: Open-loop systems reduce complexity and cost.

- Reliable and durable: Fewer moving parts mean longer motor life and low maintenance.

- Excellent response characteristics: Rapid acceleration, deceleration and reversals—ideal for precise stitch control. Stitch length can be controlled by an accuracy of 0.1 mm.

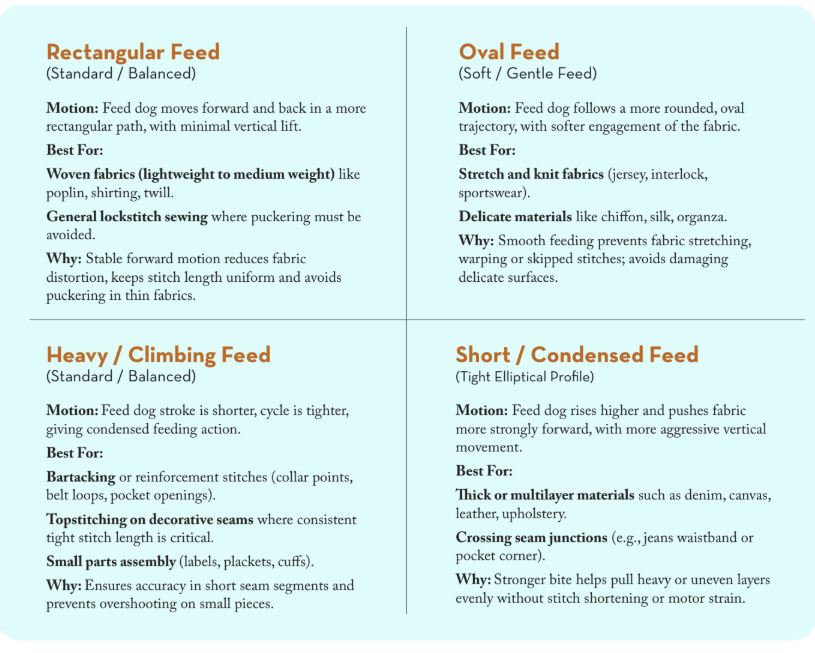

The light weight, medium weight and heavy weight concept may be a thing of the past. Because the stepper motor digitally controls the locus of the feed dog. We can now sew different fabric types more accurately in the same machine, merely by changing the feed trajectories.

Second is digital control and better sewing ergonomics. Large touchscreen panels (often with voice prompt) allow basic set-up of sewing parameters to programmable job storage, on-screen diagnostics, animated tutorials, USB connection; everything for the digital ‘touchscreen happy’ generations. Integrated needle light, higher horizontal clearance towards the right of the needle, higher vertical clearance below the machine head help in sewing ergonomics. Not only big Japanese names like Juki, Brother, but also leading Chinese brands (Jack, Gemsy, DUMA, Zoje, etc.) are offering these features in their models.

While the above features are being democratised across brands, the leaders are trying to raise the bar further. Jack A10 has taken digitalisation to a different level through cross platformisation and cross device and cross platform data connection. The embedded 3-in-1 touchscreen display combines sewing system, hanging system and production management system. A10 offers visually controlled sewing parameters setting, remote parameter adjustment, remote service request, etc.

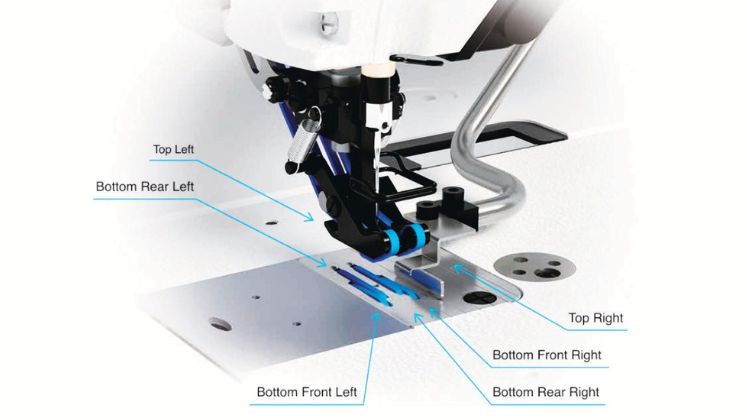

Juki DX 01 has taken deskilling to the next level. It’s the world’s first 6 belt feed assist feed mechanism which makes easing and curve join super easy.

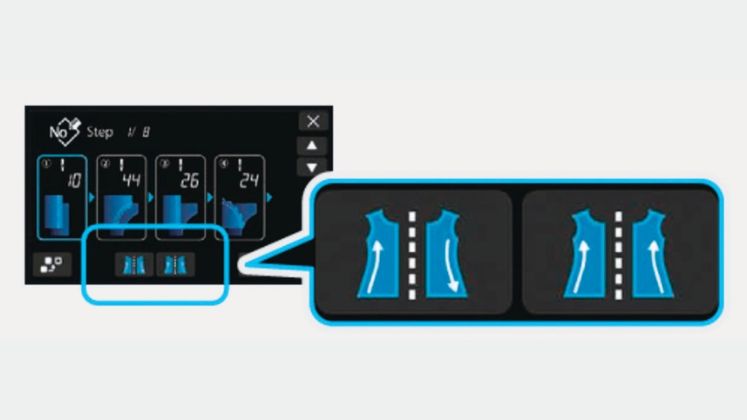

The unique feed mechanism enables independent control of the feed dog and needle bar drive. The upper and lower belt securely grip hard to feed fabrics, ensuring strong feed force during high speed and reducing defects such as skipped and jumped stitches. It’s interchangeable top feed belt and standard presser foot allows the machine to be used as a conventional drop feed machine, with unmatched flexibility. Ratio-based input for optimal feed setting, customisation of pre-registered patterns, one touch reversal of left-right sewing patterns make this a powerhouse of flexible automation.

The World’s First! 6-belt feed-assist mechanism Curved processes like easing are completed efficiently and beautifully

DX 01 also offers another world’s first customer centric innovation, ‘threadless preview’. High precision trial sewing with minimal risk of fabric damage is achieved by sewing without thread yet securely gripping the fabric between the upper and lower belts.

Now the NO part: what is surprising is that in the IoT feature category, no new sewing machine brand made an entry in CISMA. Since Brother introduced Nexio IoT sewing machine more than a decade ago, there are only three brands (Big Three) – Juki, Brother and Jack – which are struggling to make IoT a success. How far the IoT can solve the real time production data, capturing and translating into a meaning production related matrix will be the real biggest breakthrough.