Back in 2024, India marked 75 years of its Constitution—a reminder of how far the country has come in its pursuit of accountability, transparency and inclusive growth. Just a year later, another milestone quietly highlights how those very values are shaping India’s apparel industry.

In June 2025, SGS completed 75 years of operations in India, continuing its long-standing role as a trusted partner in testing, inspection and certification.

It all began in 1950, when SGS opened its first lab in Mumbai’s Worli. Since then, the company has grown with India’s manufacturing ecosystem, especially in textiles and apparel. Over the decades, SGS has supported everything from early-stage quality control to the complex demands we now see around climate action, chemical safety and supply chain transparency.

Today, as Indian fashion brands and manufacturers face growing expectations from global buyers, stricter regulations and more conscious consumers, SGS is helping the industry at every stage of the fashion supply chain. Whether working through a D2C brand to scale private labels with built-in sustainability protocols or guiding a dyeing unit in Tier-2 India through its very first carbon footprint calculation, SGS is helping embed accountability and readiness into every part of the supply chain.

With digital tools like SGS SMART and SGS Cares, full-scope PFAS testing and circularity certifications such as EN15343 and Green Mark, the company is helping Indian exporters meet the world’s toughest sustainability standards.

More importantly, it’s helping them move from ticking boxes to building real credibility—from making green claims to showing science-backed proof. This is especially critical as the industry navigates EU chemical restrictions, MRSL Level 3 protocols and Scope 3 emission expectations.

In this exclusive interview with Apparel Resources, Dipjyoti Banerjee, Executive Director, SGS walks us through how SGS is helping fashion businesses in India stay ahead—not just in compliance, but in building a more responsible future.

AR: As Indian fashion retailers and D2C brands scale up and increasingly invest in private labels—how is SGS supporting them in integrating quality assurance, restricted substances testing and sustainability compliance across vendor onboarding and product development?

We’ve seen a big shift in how India’s fashion and D2C landscape is evolving. The accelerated growth of private labels, the rise of conscious consumerism, increasing regulatory scrutiny and heightened demand for sustainable and ethically produced apparel are driving fashion retailers to reimagine their product development and supply chain strategies.

In this environment, ensuring product quality, chemical safety and sustainability compliance is no longer optional—it’s a critical differentiator for brands aiming to compete both domestically and on the global stage. To support this transformation, SGS India delivers a holistic, integrated system that empowers fashion retailers and D2C brands to confidently scale their private labels while meeting stringent quality and sustainability expectations.

We do this by leveraging a strong network of accredited labs across Chennai, Gurugram, Tirupur and Bengaluru, combined with digital platforms and globally recognised certifications. We help brands embed quality assurance, restricted substance control and sustainability across their entire product lifecycle—from vendor onboarding to market launch. One of the first steps is helping brands through Vendor Onboarding. Through our SMART digital audit platform, we make vendor evaluations smoother and more comprehensive. It gives you a clear picture of a supplier’s readiness, benchmarks them against best practices and identifies any risks early on. That’s crucial when you’re trying to scale and need partners you can rely on. When it comes to restricted substances control, we support brands with thorough testing—everything from MRSL and RSL compliance to BRS300 advanced chemical screening. We also carry out root-cause analysis to ensure any issues are addressed properly, helping brands stay aligned with both domestic laws and international chemical regulations. On the sustainability certification front, we help brands validate claims around recycled or organic content. We work with standards from Textile Exchange and also provide certifications like Green Mark, which really boost consumer trust and brand credibility.

| We offer end-to-end validation for claims such as recycled content, biodegradability and circular material compliance. SGS is also one of the few certification bodies accredited by ENAC to issue EN15343 certification, SGS provides recognised assurance for recycled plastics, a key compliance benchmark for European markets. |

Another big piece of the puzzle is traceability and reporting. Through platforms like SMART Source and SGS Cares, we offer tools that allow brands to track the full material journey, build digital product passports and prepare for upcoming regulations. These tools are designed to make sourcing more transparent and data reporting more structured, which is exactly what global buyers are looking for. We’re also seeing more demand for quality and functional testing. We provide end-to-end physical, chemical and regulatory tests across our Indian labs to ensure that every product meets performance and safety expectations. Something that’s really helped brands speed up their development process is our support for virtual sampling, remote colour approvals and digital preshipment inspections. These tools are game changers for teams looking to be agile without compromising on quality.

We also focus on building supplier capabilities. Through our training programs, we help manufacturers align their operations with the HIGG Facility Environmental Module (FEM), promoting long-term environmental improvement And finally, there’s the environmental compliance aspect. We help brands meet environmental standards through wastewater and effluent testing, eco-claim verification and assessments for CO2 footprint and recyclability – ensuring alignment with global eco-regulations. With this comprehensive support system, SGS India acts as a strategic partner to Indian fashion retailers and D2C brands, enabling them to not only meet evolving consumer and regulatory demands but also build resilient, transparent and responsible supply chains for the future.

AR: How is SGS helping Indian garment manufacturers effectively quantify and reduce their environmental footprint— whether through Scope 1, 2 and 3 emissions tracking or developing new metrics and partnerships to address water usage in dyeing and processing units?

Indian garment manufacturers face mounting pressure to measure and reduce their environmental impact – particularly in areas such as carbon emissions, water consumption and circular material usage. SGS recognises the critical need for actionable, datadriven solutions to support this transition and offers a comprehensive suite of tools and services designed to help manufacturers accurately quantify their environmental footprint, meet ESG requirements and embed cleaner, more efficient practices throughout their operations, further extending to their supply chains.

For Scope 1 and 2 emissions, which include on-site fuel combustion and purchased electricity, SGS enables accurate tracking and reduction through the SGS Carbon Digital Platform. This solution integrates utility data monitoring with globally recognised SGS Green Marks for both Product Carbon Footprint (PCF) and verified emission reduction. SGS has also partnered with Worldly (formerly HIGG Index) to align emission tracking with widely accepted sustainability reporting standards. The outcome is a measurable decrease in manufacturers’ operational greenhouse gas (GHG) emissions and a credible pathway towards carbon reduction.

For Scope 3 emissions, which account for upstream and downstream activities in the supply chain, SGS supports garment manufacturers in collecting and analysing supplier-level data through platforms like SGS SMART and Worldly. This enhanced data intake allows brands and manufacturers to gain end-to-end visibility into their extended carbon footprint and identify opportunities for targeted interventions in sourcing and logistics. To address water use and waste in dyeing and processing, SGS provides wastewater testing and consultancy services that include resource efficiency audits, circularity assessments and sustainability evaluations of water intensive processes such as Reverse Osmosis (RO) usage. For circular material claims, SGS offers verification services for recycled fibres like r-PET and validates organic content through Life Cycle Assessment (LCA) studies. This scientific verification strengthens brand trust and enhances credibility in sustainability claims, especially among environmentally conscious consumers and global buyers.

SGS strengthens ESG transparency and traceability through our digital platforms like SMART Source and SGS Cares, supported by Green Marks certification. These tools enable garment manufacturers to implement structured ESG reporting, demonstrate compliance with sustainability benchmarks and build transparent communication with stakeholders across the value chain. We also conduct social and ethical compliance assessments (e.g., SA8000, SMETA) as well as governance reviews.

AR: Many global brands now ask suppliers to meet higher levels of ZDHC MRSL compliance. How is SGS helping Indian apparel manufacturers move from Level 1 to Level 3, especially when it’s hard to track and verify chemicals used in the supply chain?

That’s a really important question because we’re seeing a clear shift in what global brands expect today. It’s no longer enough for manufacturers to just meet basic compliance or stop at ZDHC MRSL Level 1. There’s increasing pressure to move toward Level 3, which requires far more rigorous chemical transparency and control and understandably, that’s not easy in a fragmented supply chain like ours. Therefore, we’ve been working closely with apparel manufacturers to make this transition smoother and more practical. First, we’ve built the infrastructure to support this journey.

Our ZDHCcertified labs in Chennai (since May 2023) and Gurgaon (since April 2025) are fully equipped to test for MRSL v3.1 across all three levels, so brands and their suppliers can verify compliance at any stage with reliable and consistent results. One of the biggest challenges is tracking what chemicals are actually being used in wet processing. To tackle that, we use chemical formulation screening through our BRS350 analysis, which goes deep into dyes, auxiliaries and heavy metals. The results are backed by clear, auditable reports that help with supplier verification and risk assessments.

We also do a lot of On-Site Audits and Documentation Reviews. Our teams conduct chemical inventory checks, review Material Safety Data Sheets (MSDS) and perform root-cause analyses to identify any gaps. Once we have that visibility, we support the implementation of corrective action plans to help facilities get aligned with Level 3 expectations—even when visibility across the supply chain is limited. We also run hands-on workshops and training sessions around hazardous substance management and ZDHC compliance. These sessions are designed to empower manufacturers and their suppliers to build internal capabilities for long-term chemical traceability and MRSL Level 3 readiness.

| Our GHG accounting and verification services help manufacturers accurately measure Scope 1, 2 and 3 emissions, enabling alignment with science-based targets, net-zero pathways and regulatory disclosure frameworks. SGS empowers businesses to mitigate reputational risk. |

AR: Are Indian garment manufacturers seeing greater demand for sustainability verification and traceability from domestic buyers, not just international ones? How is SGS supporting this shift in the local market?

Absolutely—this shift is happening right here at home too, not just in export markets. With growing consumer awareness and increasing regulatory pressure to combat greenwashing, domestic Indian brands are placing greater emphasis on credible sustainability verification and supply chain traceability. This shift is also driven by emerging ESG compliance requirements mandated for Indian companies. To support this transition, SGS offers globally recognised certifications such as RCS (Recycled Claim Standard), GRS (Global Recycled Standard), RWS (Responsible Wool Standard) and OCS (Organic Content Standard) – enabling garment manufacturers to substantiate their sustainability claims with confidence and transparency. In addition, SGS experts assist manufacturers in accurately calculating, verifying and communicating their carbon footprint, positioning them to meet brand expectations and stay competitive as decarbonisation becomes a priority across the textile value chain.

AR: With growing regulatory scrutiny around PFAS in the EU and other key export markets, what specific testing protocols or advisory services does SGS offer to help exporters ensure compliance and stay ahead of potential bans?

You’re spot on! PFAS compliance isn’t just another regulatory box to tick, it’s fast becoming a litmus test for export readiness. Our dedicated PFAS lab in Chennai offers a full suite of advanced testing, including Total Fluorine Screening (EN 14582) to detect the presence of any fluorinebased substances in textiles. We’ve also adopted the updated EN 17681-1:2025 method, which uses alkaline hydrolysis and LC-MS/MS to pinpoint side-chain fluorinated polymers—a critical area under the EU’s regulatory radar.

We also carry out targeted PFAS analysis that aligns with both EU REACH/POPs regulations and US state-specific rules, including California’s AB 652. But where we really add value is in our regulatory advisory and Green Mark certification. We help Indian exporters go beyond compliance, supporting them in making verifiable PFAS-free claims, strengthening buyer confidence and future-proofing their sustainability profile in key global markets.

AR: As chemical recycling gains traction and EU recycling targets tighten, how are you building credibility around recyclability and circular packaging claims — and what trusted solutions are you relying on to meet these evolving standards?

We are supporting this shift by providing EN-15343 certification service to a wide range of stakeholders, including plastic manufacturers, packaging companies, recycling facilities and plastic processors, as it ensures traceability, sustainability and compliance with industry standards in the plastics value chain.

As an ENACaccredited body, we provide certification that requires a proper documentary system to be put in place. This includes control of input material, control of the recyclate production process, plastics recyclate characterisation, traceability and quality assurance and calculation of recycled content percentage. The benefits of obtaining this certification include demonstrating compliance with applicable requirements to third parties and legal regulations and moving towards a circular plastics sector by reducing reliance on single-use plastics. It also helps companies comply with obligations under the directive on single-use plastics, contribute to the SDGs, the circular economy and the 2030 agenda and reduce environmental impact—while reinforcing their commitment to sustainability and enhancing brand reputation.

AR: With frameworks like ESRS, ISSB and GRI now demanding deeper transparency, how are you aligning your sustainability reporting with global expectations—and what role does your ‘Impact Now’ initiative play in translating ESG data into real business decisions?

As the disclosure ecosystem continues to evolve, organisations are expected to report beyond subjective narratives and disclose complex ESG related information that can only be measured in presence of a robust data collation and analysis system. Further, to demonstrate progress with transparency, organisations are required to put in real-time, on-ground measures to improve the Environmental, Social & Governance related performance that shall then reflect into improved Y-O-Y trends. Since, companies can no longer afford to get away with partial or convenience reporting, it is important for them to deploy experts, resources and effort that deliver real impact.

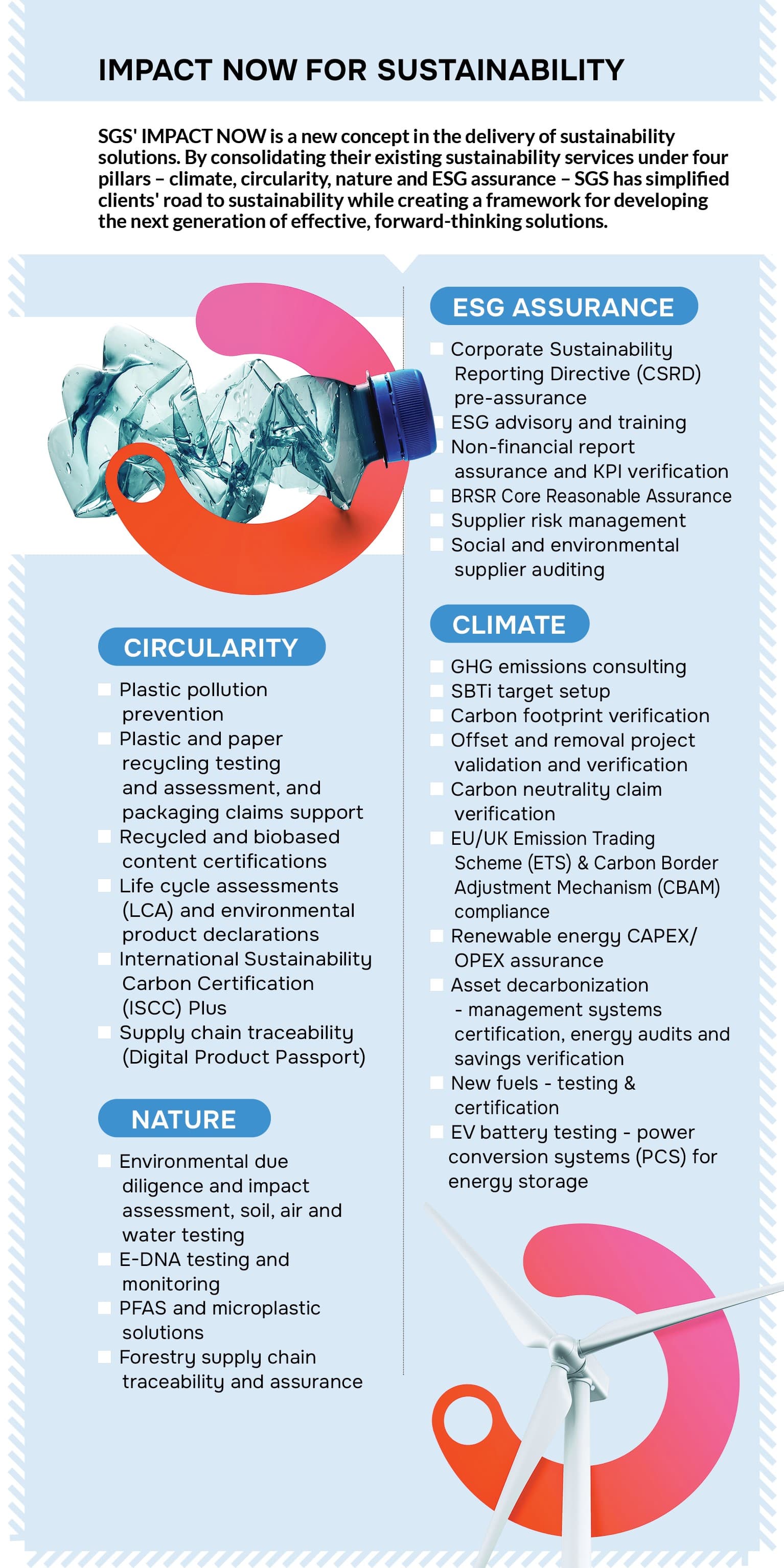

Our ‘Impact Now’ portfolio encompasses a comprehensive range of customisable services across Testing, Inspection, Certification, Assurance, Advisory and Value Chain to truly address every aspect of ESG. This holistic approach is what promises to help organisations across sectors, scales and phases of their sustainability journey. As a team of sustainability experts, we are equipped to handhold and deliver end-to-end services with respect to sustainability reporting, GHG accounting, value chain sustainability, ESG rating improvement, ESG strategy development, climate action and more.

AR: Many domestic apparel manufacturers, especially in Tier-2,Tier-3 cities, are still outside the compliance net. What challenges do you observe in bringing them up to ESG and quality standards—and how is SGS addressing that gap?

Some of the challenges that these businesses face are lack of awareness, limited resources, lack of expertise and misplaced priorities. That said, we have recently seen a shift in these players as the demand for ESG action from various stakeholders is on a rise. We often notice that buyers expect their textile supply chain partners to report on specific ESG parameters with respect to GHG emissions, waste, water, labour and other social KPIs.

Further, some of the big buyers are often listed entities on the NSE/ BSE or are located internationally. As a result, there is rising pressure on the domestic manufacturers to improve their understanding, preparation and disclosures on ESG for their buyers to fully comply with local (BRSR) and international mandates on sustainability. We are equipped to customise our services to best suit organisations in various stages of their journey. For smaller players that are just starting out, we offer gap assessments, materiality assessments, GHG Inventorisation, development of ESG policies and procedures and more.

AR: Looking ahead, how do you see sustainability compliance evolving in the Indian garment industry – which specific areas or nuances like climate disclosures, supply chain traceability or social compliance do you believe will become most critical going forward?

As the awareness and importance of sustainability continue to grow and corporate giants move toward their net-zero ambitions, the emphasis on climate disclosures, including GHG Inventorisation, reduction plans and progress shall continue to rise. Further, as the majority of environmental and social impacts occur within the supply chain, integration of sustainability in the value chain will gain momentum. SGS is not only well positioned to offer guidance and expertise to individual organisations to achieve their sustainability goals, but we can contribute to the development of sector-specific guidelines and monitoring mechanisms that promote adoption and accountability within the industry.